Dtc P0327 Knock Sensor 1 Circuit Low Input (Bank 1 Or Single Sensor)

DESCRIPTION

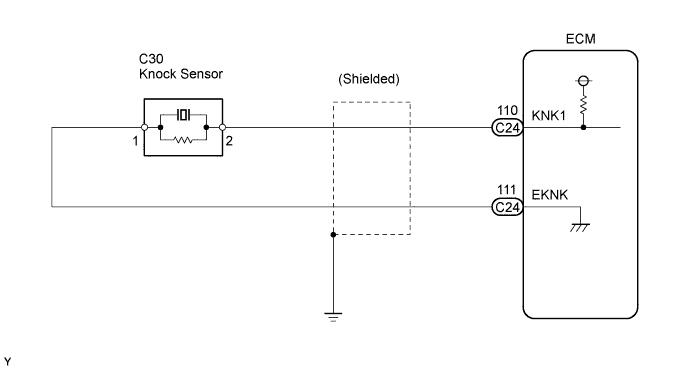

WIRING DIAGRAM

INSPECTION PROCEDURE

READ VALUE USING INTELLIGENT TESTER (KNOCK FEEDBACK VALUE)

CHECK HARNESS AND CONNECTOR (ECM - KNOCK SENSOR)

INSPECT ECM (KNK1 VOLTAGE)

INSPECT KNOCK SENSOR

DTC P0327 Knock Sensor 1 Circuit Low Input (Bank 1 or Single Sensor) |

DTC P0328 Knock Sensor 1 Circuit High Input (Bank 1 or Single Sensor) |

DESCRIPTION

Flat type knock sensors (non-resonant type) have structures that can detect vibrations over a wide band of frequencies: between approximately 6 kHz and 15 kHz. Knock sensors are fitted onto the engine block to detect engine knocking.The knock sensor contains a piezoelectric element which generates a voltage when it becomes deformed.The voltage is generated when the engine block vibrates due to knocking. Any occurrence of engine knocking can be suppressed by delaying the ignition timing.DTC No.

| DTC Detection Condition

| Trouble Area

|

P0327

| Output voltage of knock sensor is 0.5 V or less

(1 trip detection logic)

| - Short in knock sensor circuit

- Knock sensor

- ECM

|

P0328

| Output voltage of knock sensor is 4.5 V or more

(1 trip detection logic)

| - Open in knock sensor circuit

- Knock sensor

- ECM

|

- HINT:

- When any of DTCs P0327 and P0328 are set, the ECM enters fail-safe mode. During fail-safe mode, the ignition timing is delayed to its maximum retardation. Fail-safe mode continues until the ignition switch is turned off.

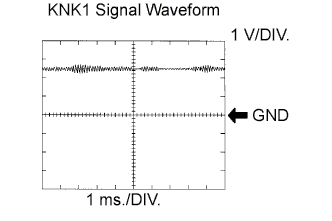

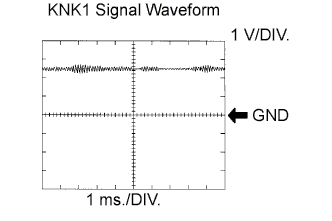

Reference: Inspection using an oscilloscope The correct waveform is as shown.

The correct waveform is as shown.Item

| Content

|

Terminals

| KNK1 - EKNK

|

Equipment Settings

| 1 V/DIV.

1 ms./DIV.

|

Conditions

| Keep engine speed at 4,000 rpm with warm engine

|

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

- Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

| 1.READ VALUE USING INTELLIGENT TESTER (KNOCK FEEDBACK VALUE) |

Connect the intelligent tester to the DLC3.

Start the engine and turn the tester on.

Warm up the engine.

Select the following menu items: Powertrain / Engine and ECT / Data List / Knock Feedback Value.

Read the values displayed on the tester while driving the vehicle.

- Standard:

- The values change.

- HINT:

Malfunction does not occur

| Knock Feedback Values change

|

Malfunctions occur

| Knock Feedback Values do not change

|

- The knock feedback value change can be confirmed by running the engine with a high load, for example, by activating the air conditioning system and racing the engine.

| OK |

|

|

|

| CHECK FOR INTERMITTENT PROBLEMS |

|

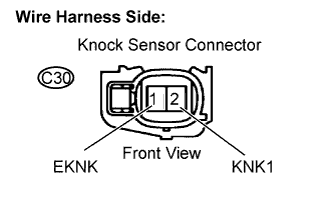

| 2.CHECK HARNESS AND CONNECTOR (ECM - KNOCK SENSOR) |

Disconnect the C24 ECM connector.

Measure the resistance between the terminals.

- Standard resistance:

Tester Connection

| Specified Condition

|

KNK1 (C24-110) - EKNK (C24-111)

| 120 to 280 kΩ at 20°C (68°F)

|

Reconnect the ECM connector.

| 3.INSPECT ECM (KNK1 VOLTAGE) |

Disconnect the C30 knock sensor connector.

Turn the ignition switch to the ON position.

Measure the voltage between the knock sensor terminals.

- Standard voltage:

Tester Connection

| Specified Condition

|

KNK1 (C30-2) - EKNK (C30-1)

| 4.5 to 5.5 V

|

Reconnect the knock sensor connector.

| OK |

|

|

|

| CHECK FOR INTERMITTENT PROBLEMS |

|

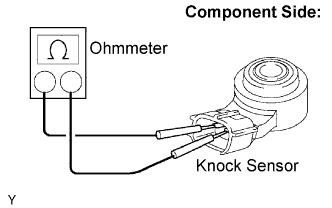

Remove the knock sensor.

Measure the resistance between the terminals.

- Standard resistance:

Tester Connection

| Specified Condition

|

KNK1 (2) - EKNK (1)

| 120 to 280 kΩ at 20°C (68°F)

|

Reinstall the knock sensor.

| OK |

|

|

|

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|