Dtc P0010 Camshaft Position A Actuator Circuit (Bank 1)

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

PERFORM ACTIVE TEST USING INTELLIGENT TESTER (OPERATE OCV)

INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY

CHECK HARNESS AND CONNECTOR (OCV - ECM)

DTC P0010 Camshaft Position "A" Actuator Circuit (Bank 1) |

DESCRIPTION

- HINT:

- This DTC relates to the Oil Control Valve (OCV).

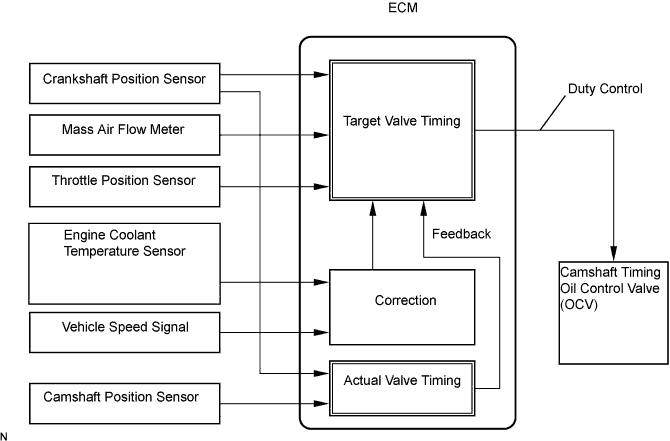

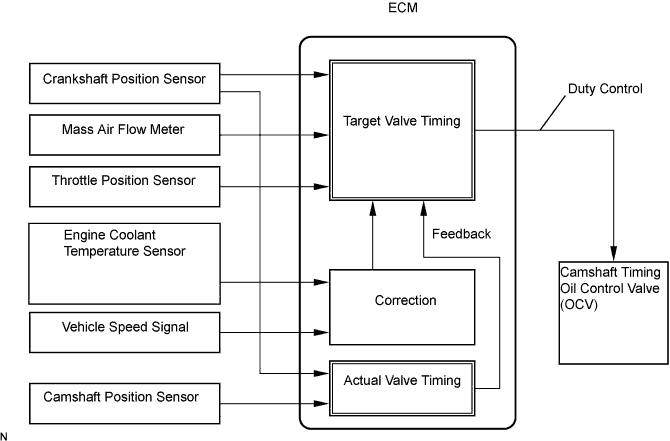

The Variable Valve Timing (VVT) system includes the ECM, OCV and VVT controller. The ECM sends a target duty-cycle control signal to the OCV. This control signal regulates the oil pressure applied to the VVT controller. Camshaft timing control is performed according to engine operating conditions such as the intake air volume, throttle valve position and engine coolant temperature. The ECM controls the OCV, based on the signals transmitted by several sensors. The VVT controller regulates the intake camshaft angle using oil pressure through the OCV. As a result, the relative positions of the camshaft and crankshaft are optimized, the engine torque and fuel economy improve, and the exhaust emissions decrease under overall driving conditions. The ECM detects the actual intake valve timing using signals from the camshaft and crankshaft position sensors, and performs feedback control. This is how the target intake valve timing is verified by the ECM.

DTC No.

| DTC Detection Condition

| Trouble Area

|

P0010

| Open or short in OCV circuit

(1 trip detection logic)

| - Open or short in OCV circuit

- OCV

- ECM

|

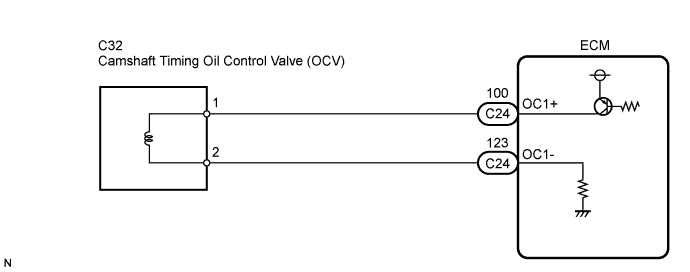

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

- Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

| 1.PERFORM ACTIVE TEST USING INTELLIGENT TESTER (OPERATE OCV) |

Connect the intelligent tester to the DLC3.

Start the engine and turn the tester on.

Warm up the engine.

Select the following menu items: Powertrain / Engine and ECT / Active Test / Control the VVT System (Bank 1).

Check the engine speed while operating the Oil Control Valve (OCV) using the tester.

- OK:

Tester Operation

| Specified Condition

|

OCV OFF

| Normal engine speed

|

OCV ON

| Engine idles roughly or stalls

(soon after OCV switched from OFF to ON)

|

| OK |

|

|

|

| CHECK FOR INTERMITTENT PROBLEMS |

|

| 2.INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY |

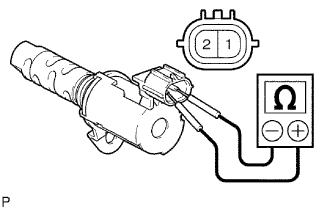

Disconnect the C32 OCV connector.

Measure the resistance between the terminals of the OCV.

- Standard resistance:

- 6.9 to 7.9 Ω at 20°C (68°F)

Reconnect the OCV connector.

| | REPLACE CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY |

|

|

| 3.CHECK HARNESS AND CONNECTOR (OCV - ECM) |

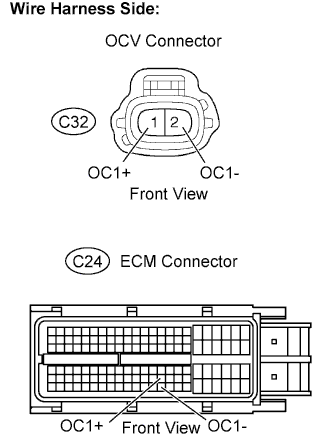

Disconnect the C32 OCV connector.

Disconnect the C24 ECM connector.

Measure the resistance between the terminals of the wire harness side.

- Standard resistance (Check for open):

Tester Connection

| Specified Condition

|

OC1+ (C32-1) - OC1+ (C24-100)

| Below 1 Ω

|

OC1- (C32-2) - OC1- (C24-123)

|

- Standard resistance (Check for short):

Tester Connection

| Specified Condition

|

OC1+ (C32-1) or OC1+ (C24-100) - Body ground

| 10 kΩ or higher

|

OC1- (C32-2) or OC1- (C24-123) - Body ground

|

Reconnect the OCV connector.

Reconnect the ECM connector.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|