Dtc B2282 Vehicle Speed Signal Malfunction

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK CAN COMMUNICATION SYSTEM

CHECK SPEEDOMETER OPERATION

READ VALUE USING INTELLIGENT TESTER

CHECK HARNESS AND CONNECTOR (MAIN BODY ECU - COMBINATION METER ASSEMBLY)

INSPECT COMBINATION METER ASSEMBLY (SPEED SIGNAL)

CHECK HARNESS AND CONNECTOR (JUNCTION BLOCK - MAIN BODY ECU)

CHECK HARNESS AND CONNECTOR (JUNCTION BLOCK - COMBINATION METER ASSEMBLY)

DTC B2282 Vehicle Speed Signal Malfunction |

DESCRIPTION

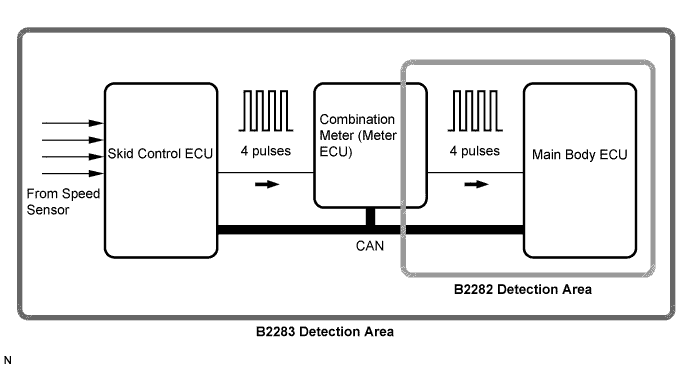

The main body ECU and the combination meter are connected by a cable and the CAN. DTC B2282 is output when: 1) the cable information and CAN information are inconsistent; and 2) a malfunction is detected between the vehicle speed sensor and combination meter.- HINT:

- When the main body ECU is replaced with a new one and the negative (-) battery terminal is connected, the power source mode becomes the IG-ON mode. When the battery is removed and reinstalled, the power source mode that was selected when the battery was removed is restored.

- After the main body ECU is replaced, perform the registration procedures for the engine immobiliser system.

DTC No.

| DTC Detection Condition

| Trouble Area

|

B2282

| When both conditions below are met:

- Cable information and CAN information between the main body ECU and the combination meter are inconsistent

- Malfunction is detected between the vehicle speed sensor and the combination meter

| - CAN communication system

- Combination meter system

- Main body ECU

- Wire harness or connector

|

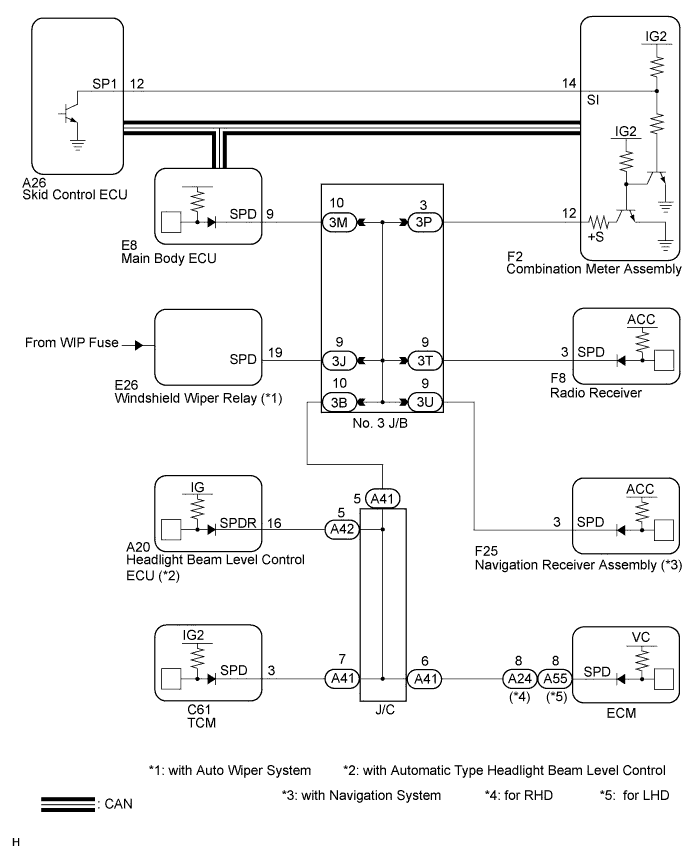

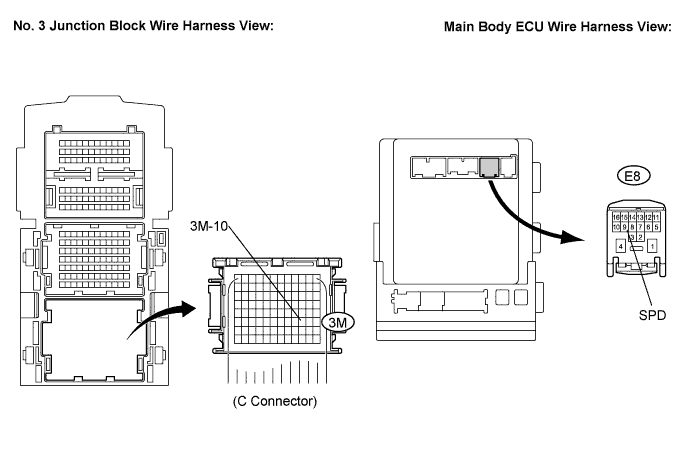

WIRING DIAGRAM

- HINT:

- A voltage of 12 V or 5 V is output from each ECU and then input to the combination meter. The signal is changed to a pulse signal at the transistor in the combination meter. Each ECU controls the respective system based on the pulse signal.

- If a short occurs in an ECU, all systems in the diagram above will not operate normally.

INSPECTION PROCEDURE

| 1.CHECK CAN COMMUNICATION SYSTEM |

Check if CAN communication DTCs are output (for LHD: CAMRY_ACV40 RM000000WI605LX.html) (for RHD: CAMRY_ACV40 RM000000WI605KX.html).

- HINT:

- If any DTCs for CAN communication system malfunction are output, inspect those DTCs first.

- Result:

Result

| Proceed to

|

CAN communication DTC is not output.

| A

|

CAN communication DTC is output (for LHD).

| B

|

CAN communication DTC is output (for RHD).

| C

|

| 2.CHECK SPEEDOMETER OPERATION |

Connect the intelligent tester to the DLC3.

Turn the engine switch on (IG).

Turn the intelligent tester on.

Enter the following menus: Body / Combination Meter / Data List.

Read the Data List according to the display on the intelligent tester.

Combination MeterTester Display

| Measurement Item/Range

| Normal Condition

| Diagnostic Note

|

Vehicle Speed Meter

| Vehicle speed/Min.: 0, Max.: 255

| Almost same as actual speed (When driving)

| -

|

| 3.READ VALUE USING INTELLIGENT TESTER |

Enter the following menus: Body / Body / Data List.

Read the Data List according to the display on the intelligent tester.

BodyTester Display

| Measurement Item/Range

| Normal Condition

| Diagnostic Note

|

Vehicle speed signal

| Vehicle speed signal/Stop or Run

| Stop: Vehicle stopped

Run: Vehicle running

| -

|

- OK:

- Stop (vehicle is sopped) and Run (vehicle is running) appear on the screen.

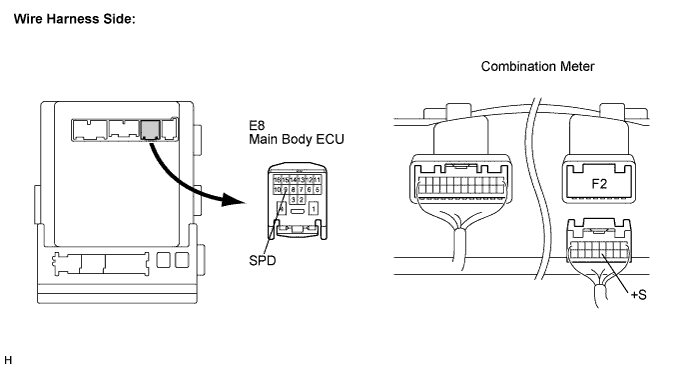

| 4.CHECK HARNESS AND CONNECTOR (MAIN BODY ECU - COMBINATION METER ASSEMBLY) |

Disconnect the E8 ECU connector.

Disconnect the F2 meter connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

E8-9 (SPD) - F2-12 (+S)

| Always

| Below 1Ω

|

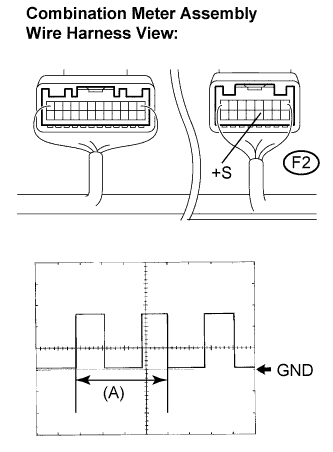

| 5.INSPECT COMBINATION METER ASSEMBLY (SPEED SIGNAL) |

Remove the combination meter assembly (CAMRY_ACV40 RM0000024D701JX.html).

Reconnect the F15 connector to the combination meter assembly.

Reconnect the E8 connector to the main body ECU.

Connect an oscilloscope to terminal F15-3 (SPD) and body ground.

Turn the engine switch on (IG).

Turn the wheel slowly.

Check the signal waveform according to the condition(s) in the table below.

Item

| Condition

|

Tool setting

| 5 V/DIV., 10 ms./DIV.

|

Vehicle condition

| Driving at approx. 20 km/h (12 mph)

|

- OK:

- The waveform is displayed as shown in the illustration.

- HINT:

- When the system is functioning normally, one wheel revolution generates 4 pulses. As the vehicle speed increase, the width indicated by (A) in the illustration narrows.

| 6.CHECK HARNESS AND CONNECTOR (JUNCTION BLOCK - MAIN BODY ECU) |

Disconnect the 3M connector from the No. 3 junction block.

Measure the resistance according to the value(s) in the tale below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

3M-10 - E8-9 (SPD)

| Always

| Below 1 Ω

|

3M-10 - Body ground

| Always

| 10 kΩ or higher

|

- HINT:

- If the result of the inspection for a short circuit is not as specified, there may be a short in the ECU.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR (JUNCTION BLOCK - MAIN BODY ECU) |

|

|

| 7.CHECK HARNESS AND CONNECTOR (JUNCTION BLOCK - COMBINATION METER ASSEMBLY) |

Disconnect the 3P connector from the No. 3 junction block.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

3P-3 - F2-12 (+S)

| Always

| Below 1 Ω

|

3P-3 - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR (JUNCTION BLOCK - COMBINATION METER ASSEMBLY) |

|

|