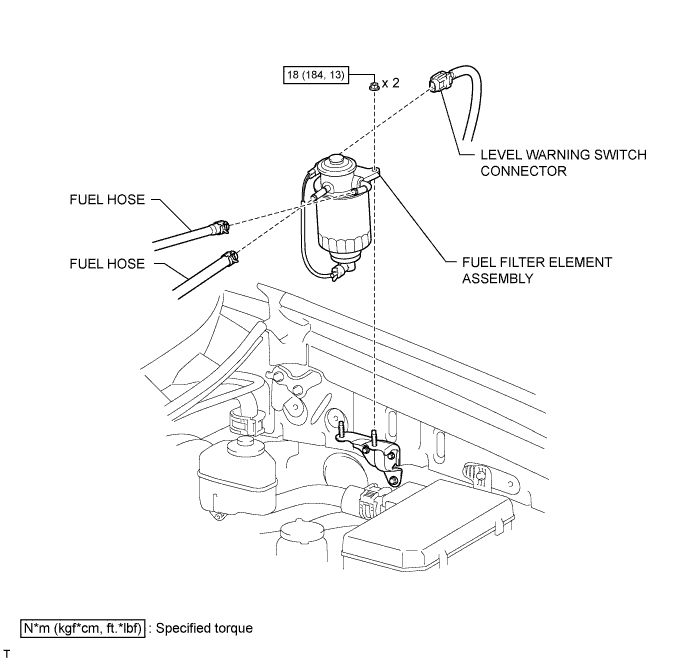

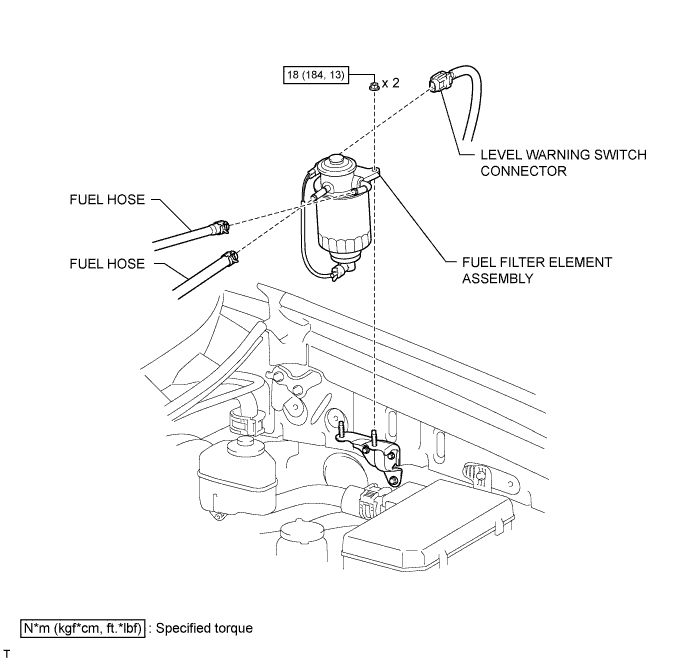

Топливный Фильтр - Узлы И Детали

Land Cruiser Prado GRJ150 TRJ150 TRJ155 KDJ150 TRJ155 LJ150 - ТОПЛИВНАЯ СИСТЕМА ДВИГАТЕЛЯ 5L-E

ТОПЛИВНЫЙ ФИЛЬТР - УЗЛЫ И ДЕТАЛИ

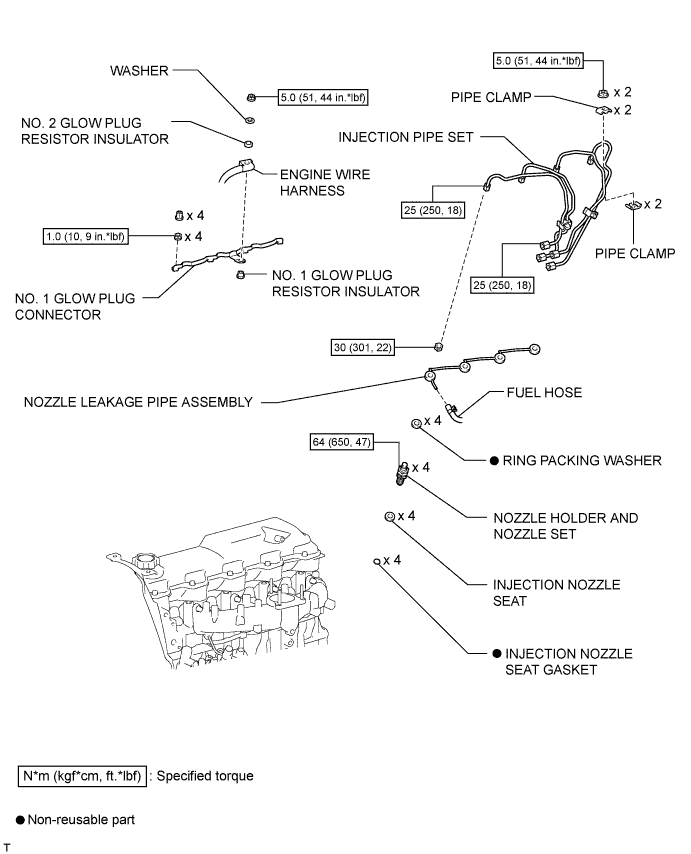

| 1. INSTALL NOZZLE HOLDER AND NOZZLE SET |

Install 4 new injection nozzle seat gaskets and the 4 injection nozzle seats to the injection nozzle holes of the cylinder head.

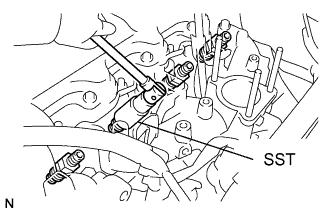

Using SST, install the 4 nozzle holder and nozzle sets.

| 2. INSTALL NOZZLE LEAKAGE PIPE ASSEMBLY |

Install 4 new ring packing washers and the leakage pipe with the 4 nuts.

Connect the fuel hose to the leakage pipe.

| 3. INSTALL NO. 1 GLOW PLUG CONNECTOR |

Install the No. 1 glow plug resistor insulator and No. 1 glow plug connector.

Install the glow plug connector with the 4 nuts. Uniformly tighten the nuts.

| *1 | Nut |

| *2 | Washer |

| *3 | No. 2 Glow Plug Resistor Insulator |

| *4 | Engine Wire |

| *5 | No. 1 Glow Plug Connector |

| *6 | No. 1 Glow Plug Resistor Insulator |

| *7 | Bolt |

Install the 4 screw grommets.

Connect the engine wire and install the No. 2 glow plug resistor insulator and washer with the bolt.

| 4. INSTALL INJECTION PIPE SET |

Install the 2 lower clamps to the intake manifold.

Install the 4 injection pipes.

| *a | for Injection Nozzle Side |

| *b | for Injection Pump Side |

Install the 2 upper pipe clamps with the 2 nuts.

| 5. INSTALL DIESEL THROTTLE BODY |

Install the diesel throttle body (See page ).

| 6. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

| 7. BLEED INJECTION PIPE |

Move the hand pump on the upper part of the fuel filter up and down and fill the injection pump and fuel system with fuel.

Loosen one of the union nuts (on the nozzle side).

Crank the engine until fuel comes out from the union nut connection (on the nozzle side).

Tighten the union nut.

Perform the procedures above for each injection pipe.

| 8. INSPECT FOR FUEL LEAK |

Check that there are no fuel leaks anywhere in the fuel system after performing maintenance.

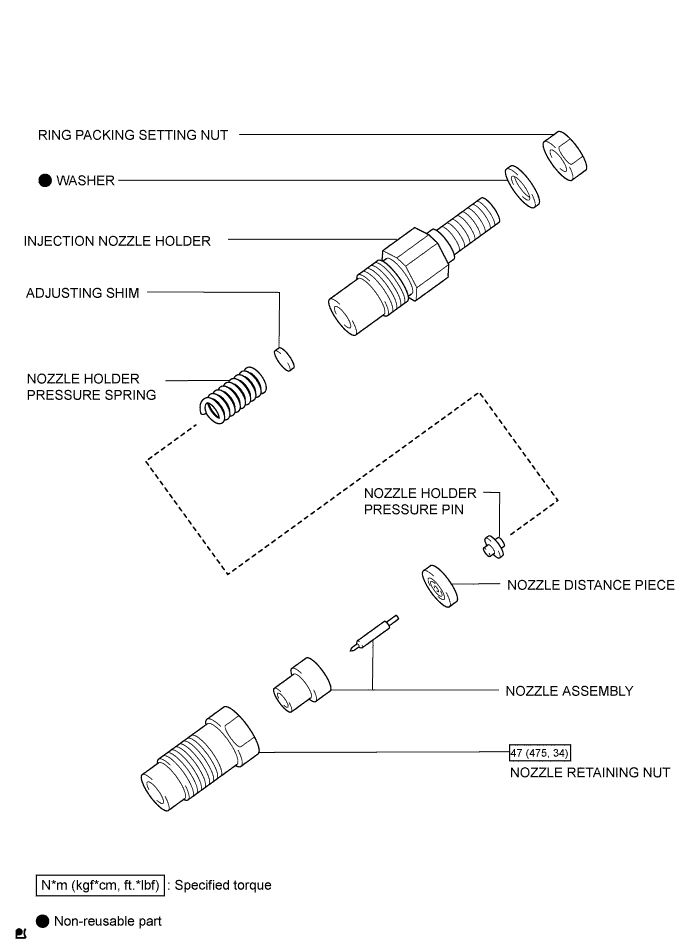

| 1. INSTALL NOZZLE RETAINING NUT |

Install the pressure pin, distance piece and nozzle assembly to the nozzle retaining nut.

Install the nozzle holder pressure spring and adjusting shim, and then temporarily install the nozzle holder to the nozzle retaining nut.

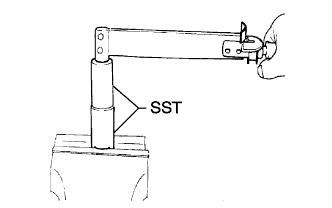

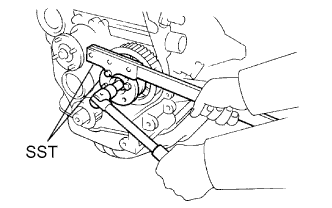

Using SST, tighten the nozzle retaining nut.

Inspect the holder and nozzle set.

| 2. INSTALL RING PACKING SETTING NUT |

Install a new washer and the ring packing setting nut.

| 1. INSPECT NOZZLE HOLDER AND NOZZLE SET |

Pressure test:

Install the nozzle holder to an injection nozzle hand tester and bleed air from the union nut connection.

Pump the tester handle a few times as fast as possible to discharge the carbon from the injection hole.

Pump the tester handle slowly and observe the pressure gauge.

Read the pressure gauge just as the injection pressure begins to drop.

| Specified Condition | ||

| 0.900 mm (0.0354 in.) | 1.300 mm (0.0512 in.) | 1.700 mm (0.0669 in.) |

| 0.950 mm (0.0374 in.) | 1.350 mm (0.0531 in.) | 1.750 mm (0.0709 in.) |

| 1.000 mm (0.0394 in.) | 1.400 mm (0.0551 in.) | 1.800 mm (0.0728 in.) |

| 1.050 mm (0.0413 in.) | 1.450 mm (0.0571 in.) | 1.850 mm (0.0728 in.) |

| 1.100 mm (0.0433 in.) | 1.500 mm (0.0591 in.) | 1.900 mm (0.0748 in.) |

| 1.150 mm (0.0453 in.) | 1.550 mm (0.0610 in.) | 1.950 mm (0.0768 in.) |

| 1.200 mm (0.0472 in.) | 1.600 mm (0.0630 in.) | - |

| 1.250 mm (0.0492 in.) | 1.650 mm (0.0650 in.) | - |

Leakage test:

While maintaining pressure at approximately 981 to 1961 kPa (10.0 to 20.0 kgf/cm2, 142 to 284 psi) below the injection pressure (adjust using the tester handle), check that there is no dripping from the injection hole or around the retaining nut for 10 seconds.

| *a | No Good |

| *b | Good |

If the nozzle drips within 10 seconds, replace or clean and overhaul the nozzle assembly.

Spray pattern test:

The injection nozzle should shudder at a certain pumping speed between 30 and 60 times per minute.

Check the spray pattern during shuddering.

| *a | No Good |

| *b | Good |

If the spray pattern is not correct during shuddering, replace or clean the nozzle.

| 2. CLEAN NOZZLE ASSEMBLY |

Using a wooden stick and brass brush, clean the nozzle.

Using a wooden stick, remove the carbon adhering to the nozzle needle tip.

| *1 | Wooden Stick |

Using a brass brush, remove the carbon from the exterior of the nozzle body (except lapped surface).

| 3. INSPECT NOZZLE ASSEMBLY |

Wash the nozzle in clean diesel fuel.

Perform the following test several times, rotating the needle slightly each time.

Tilt the nozzle body approximately 60° and pull the needle out approximately one third of its length.

Check that the needle falls into the body vent smoothly by its own weight when released.

If the needle does not fall smoothly, replace the nozzle assembly.

| 1. REMOVE RING PACKING SETTING NUT |

Remove the ring packing setting nut and washer.

| 2. REMOVE NOZZLE RETAINING NUT |

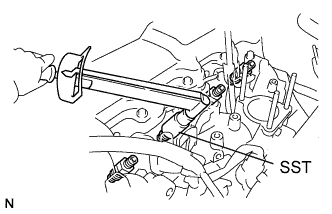

Using SST, remove the nozzle retaining nut.

| 3. REMOVE NOZZLE HOLDER PRESSURE SPRING |

| 4. REMOVE ADJUSTING SHIM |

| 5. REMOVE NOZZLE HOLDER PRESSURE PIN |

| 6. REMOVE NOZZLE DISTANCE PIECE |

| 7. REMOVE NOZZLE ASSEMBLY |

| 1. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL |

| 2. REMOVE DIESEL THROTTLE BODY |

Remove the diesel throttle body (See page ).

| 3. REMOVE INJECTION PIPE SET |

Using a union nut wrench, loosen the 8 union nuts of the 4 injection pipes.

| *1 | Union Nut Wrench |

| *a | for Injection Nozzle Side |

| *b | for Injection Pump Side |

Remove the 2 nuts, 2 upper pipe clamps and 4 injection pipes with 2 lower pipe clamps.

| 4. REMOVE NO. 1 GLOW PLUG CONNECTOR |

Remove the nut, No. 2 glow plug resistor insulator and washer and disconnect the wire harness.

Remove the 4 screw grommets and 4 nuts.

Remove the No. 1 glow plug connector and No. 1 glow plug resistor insulator.

| 5. REMOVE NOZZLE LEAKAGE PIPE ASSEMBLY |

Disconnect the fuel hose from the leakage pipe.

Remove the 4 nuts, leakage pipe and 4 ring packing washers.

| 6. REMOVE NOZZLE HOLDER AND NOZZLE SET |

Using SST, remove the 4 injection nozzles, 4 injection nozzle seats and 4 injection nozzle seat gaskets.

| 1. INSTALL INJECTION PUMP ASSEMBLY |

Temporarily install the injection pump to the timing gear case with the 2 nuts.

Temporarily install the injection pump stay to the injection pump rear end with the 3 bolts.

Rotate the pump body to align the marks on the pump flange and timing gear case.

Tighten the 2 nuts.

Tighten the 3 bolts.

Connect the 3 fuel hoses.

Connect the 5 connectors and attach the wire harness clamp.

| 2. INSTALL INJECTION PUMP DRIVE PULLEY |

Using SST, install the injection pump drive pulley with the nut.

| 3. INSTALL INJECTION PIPE SET |

Install the 2 lower clamps to the intake manifold.

Install the 4 injection pipes.

| *a | for Injection Nozzle Side |

| *b | for Injection Pump Side |

Install the 2 upper pipe clamps with the 2 nuts.

| 4. INSTALL DIESEL THROTTLE BODY |

Install the diesel throttle body (See page ).

| 5. INSTALL TIMING BELT |

Install the timing belt (See page ).

| 6. BLEED INJECTION PIPE |

Move the hand pump on the upper part of the fuel filter up and down and fill the injection pump and fuel system with fuel.

Loosen one of the union nuts (on the nozzle side).

Crank the engine until fuel comes out from the union nut connection (on the nozzle side).

Tighten the union nut.

Perform the procedures above for each injection pipe.

| 1. INSTALL DELIVERY VALVE HOLDER |

Install 4 new gaskets and the 4 valves to the distributive head.

Install the 4 springs to the 4 delivery valve holders.

Using SST, install the delivery holders.

| 2. INSTALL DISTRIBUTIVE HEAD PLUG |

Install a new O-ring to the distributive head plug.

Using SST, install the head plug.

| 3. INSTALL TIMING CONTROL VALVE |

Using a 5 mm hexagon wrench, install the timing control valve with the 2 bolts.

| *1 | 5 mm Hexagon Wrench |

| 4. INSTALL FUEL FILTER TO INJECTION PUMP FUEL PIPE |

Install a new washer and the hollow screw.

Install 2 new washers and the fuel pipe with the cap nut.

Install the wiring bracket with the bolt.

| 5. INSTALL NO. 4 NOZZLE LEAKAGE PIPE |

Install 2 new washers and the nozzle leakage pipe with the overflow screw.

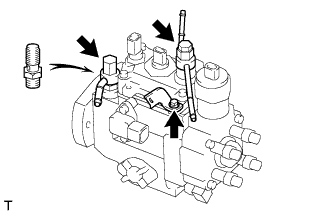

| 1. INSPECT INJECTION PUMP |

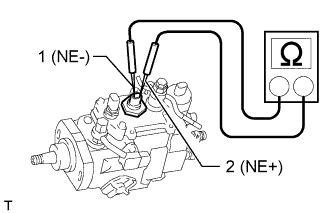

Inspect the engine speed sensor.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| 1 (NE-) - 2 (NE+) | 20°C (68°F) | 205 to 255 Ω |

If the result is not as specified, replace the injection pump assembly.

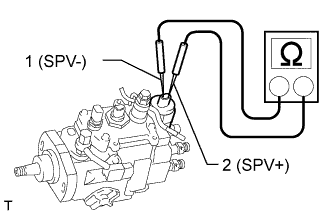

Inspect the spill control valve.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| 1 (SPV-) - 2 (SPV+) | 20°C (68°F) | 1 to 2 Ω |

If the result is not as specified, replace the injection pump assembly.

Inspect the fuel temperature sensor.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| 1 (E2) - 2 (THF) | 20°C (68°F) | 2.21 to 2.69 kΩ |

If the result is not as specified, replace the injection pump assembly.

| 2. INSPECT TIMING CONTROL VALVE |

Inspect the timing control valve.

Measure the resistance according to the value(s) in the table below.

| Tester Connection | Condition | Specified Condition |

| 1 (+B) - 2 (TCV) | 20°C (68°F) | 10 to 14 Ω |

If the result is not as specified, replace the timing control valve.

Inspect the timing control valve operation.

Connect the positive (+) lead of the battery to the timing control valve +B terminal.

Connect the negative (-) lead of the battery to the timing control valve TCV terminal.

Check that the solenoid makes a "click" sound.

If the result is not as specified, replace the timing control valve.

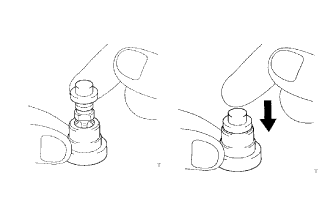

| 3. INSPECT INJECTION PUMP DELIVERY VALVE SUB-ASSEMBLY |

Pull up the valve and release it. Check that it sinks smoothly into the valve seat. If the operation is not as specified, replace the valve and valve seat as a set.