DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK CRANKING

READ VALUE USING INTELLIGENT TESTER (STARTER SIGNAL)

INSPECT STARTER RELAY (ST)

CHECK HARNESS AND CONNECTOR (STARTER RELAY - PNP SWITCH)

CHECK STARTER RELAY (POWER SOURCE)

INSPECT STARTER

INSPECT STARTER CUT RELAY (ST CUT)

CHECK HARNESS AND CONNECTOR (ST CUT RELAY - PNP SWITCH, ECM)

INSPECT PARK/NEUTRAL POSITION SWITCH

CHECK HARNESS AND CONNECTOR (PNP SWITCH - ECM)

CHECK HARNESS AND CONNECTOR (MAIN BODY ECU - ECM)

CHECK HARNESS AND CONNECTOR (STARTER CUT RELAY - PNP SWITCH, ECM)

REPLACE ECM

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

SFI SYSTEM - Cranking Holding Function Circuit

DESCRIPTION

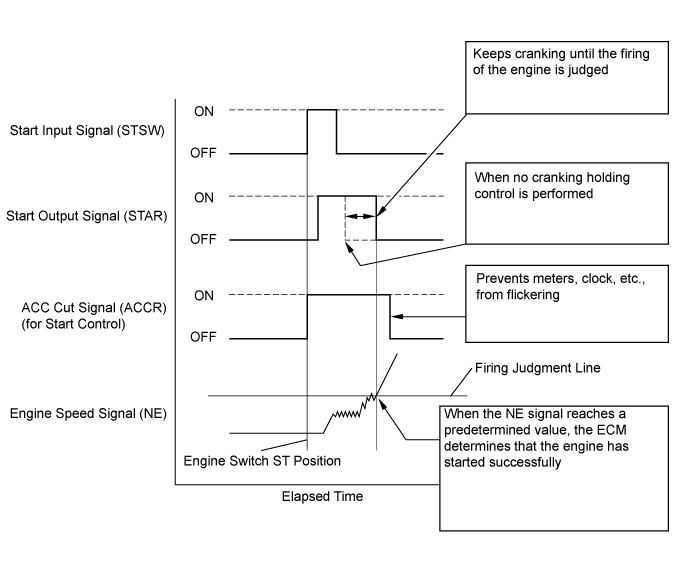

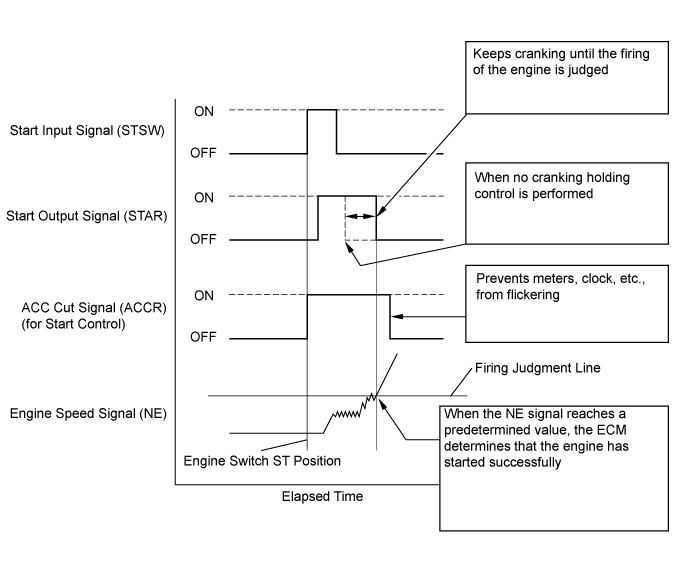

The cranking holding control system provides current to the starter when the ECM detects the engine switch start signal (STSW). When the ECM performs a firing judgment, the system cuts current to the starter. When an ECM receives the STSW signal, it turns on the ACC cut, which prevents flickering of the combination meter, clock, audio system, etc. Also, the ECM sends a signal to the ECM STAR terminal. Then the STAR output signal travels through the Park/Neutral Position (PNP) switch to the starter relay, causing the starter to activate.

When the engine is cranking, the starter operation signal is sent to the ECM STA terminal.

WIRING DIAGRAM

Refer to DTC P0617 ().

INSPECTION PROCEDURE

Check the cranking of the engine.

Result| Result | Proceed to |

| Cranking possible and holding control operates | A |

| Does not crank | B |

| Cranking possible but holding control does not operate | C |

| A | |

| |

| PROCEED TO NEXT CIRCUIT INSPECTION SHOWN IN PROBLEM SYMPTOMS TABLE ()

|

|

| 2.READ VALUE USING INTELLIGENT TESTER (STARTER SIGNAL) |

Connect the intelligent tester to the DLC3.

Turn the engine switch on (IG).

Enter the following menus: Powertrain / Engine and ECT / Data List / Starter Signal.

Check the value displayed on the tester when the engine switch is turned to the START.

- Standard:

| Engine Switch Position | Display (Starter Signal) |

| On (IG) | OFF |

| START | ON |

| 3.INSPECT STARTER RELAY (ST) |

Inspect the starter relay (ST) ().

| 4.CHECK HARNESS AND CONNECTOR (STARTER RELAY - PNP SWITCH) |

Remove the starter relay (ST) from the engine room relay block.

Disconnect the C24 PNP switch.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

| Tester Connection | Condition | Specified Condition |

| ST relay (2) - C24-5 | Always | Below 1 Ω |

| ST relay (2) or C24-5 - Body ground | Always | 10 kΩ or higher |

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 5.CHECK STARTER RELAY (POWER SOURCE) |

Remove the ST relay from the engine room relay block.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

| Tester Connection | Condition | Specified Condition |

| ST relay (1) - ST relay (5) | Always | 11 to 14 V |

| | REPAIR OR REPLACE HARNESS OR CONNECTOR (STARTER RELAY (ST) - BATTERY, BODY GROUND) |

|

|

| | REPAIR OR REPLACE STARTER ()

|

|

|

| OK | |

| |

| REPAIR OR REPLACE HARNESS OR CONNECTOR (STARTER - STARTER RELAY (ST), BATTERY) |

|

| 7.INSPECT STARTER CUT RELAY (ST CUT) |

Inspect the starter cut relay (ST CUT) ().

| | REPLACE STARTER CUT RELAY |

|

|

| 8.CHECK HARNESS AND CONNECTOR (ST CUT RELAY - PNP SWITCH, ECM) |

Remove the starter cut relay (ST CUT) from the engine room relay block.

Disconnect the C24 PNP switch connector.

Disconnect the C45 ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

| Tester Connection | Condition | Specified Condition |

| ST CUT relay (5) - C45-16 (STAR) | Always | Below 1 Ω |

| ST CUT relay (3) - C24-4 | Always | Below 1 Ω |

| ST CUT relay (5) or C45-16 (STAR) - Body ground | Always | 10 kΩ or higher |

| ST CUT relay (3) or C24-4 - Body ground | Always | 10 kΩ or higher |

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 9.INSPECT PARK/NEUTRAL POSITION SWITCH |

Inspect the park/neutral position switch ().

| | REPLACE PARK/NEUTRAL POSITION SWITCH ()

|

|

|

| 10.CHECK HARNESS AND CONNECTOR (PNP SWITCH - ECM) |

Disconnect the C24 PNP switch connector.

Disconnect the A38 ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

| Tester Connection | Condition | Specified Condition |

| C24-5 - A38-46 (STA) | Always | Below 1 Ω |

| C24-5 or A38-46 (STA) - Body ground | Always | 10 kΩ or higher |

Result| Result | Proceed to |

| NG | A |

| OK | B |

| A | |

| |

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

| 11.CHECK HARNESS AND CONNECTOR (MAIN BODY ECU - ECM) |

Disconnect the E4 main body ECU connector.

Disconnect the A38 ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

| Tester Connection | Condition | Specified Condition |

| E4-4 (STSW) - A38-14 (STSW) | Always | Below 1 Ω |

| E4-4 (STSW) or A38-14 (STSW) - Body ground | Always | 10 kΩ or higher |

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 12.CHECK HARNESS AND CONNECTOR (STARTER CUT RELAY - PNP SWITCH, ECM) |

Remove the starter cut relay (ST CUT) from the engine room relay block.

Disconnect the C24 PNP switch connector.

Disconnect the C45 ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

| Tester Connection | Condition | Specified Condition |

| ST CUT relay (5) - C45-16 (STAR) | Always | Below 1 Ω |

| ST CUT relay (3) - C24-4 | Always | Below 1 Ω |

| ST CUT relay (5) or C45-16 (STAR) - Body ground | Always | 10 kΩ or higher |

| ST CUT relay (3) or C24-4 - Body ground | Always | 10 kΩ or higher |

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 14.CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

Check the starter operation.

- OK:

- Malfunction has been repaired successfully.

| | GO TO ENTRY AND START SYSTEM (ENGINE DOES NOT START) ()

|

|

|