Land Cruiser URJ200 URJ202 GRJ200 VDJ200 - 1VD-FTV INTAKE / EXHAUST

EXHAUST MANIFOLD W/ TURBOCHARGER - SYSTEM DESCRIPTION

This section should be used as a guide for troubleshooting when the turbocharger is suspected as the cause of a problem.

| OUTLINE OF TURBOCHARGER FAILURE |

State of Turbocharger Failure Repair:

It is well known that turbocharger malfunctions cause many symptoms as shown below. However, the mechanisms resulting in these symptoms that indicate turbocharger malfunctions are not well understood. As a result, many unnecessary turbocharger replacements and other repairs are being performed due to lack of knowledge about the turbocharger and turbocharger failure. Therefore, knowing the facts regarding turbocharger malfunctions is useful for making effective repairs and saving time.

Turbocharger Failure Classification

| Symptom | Symptom Description | See page | |

| Noise | Whistling noise | Continuous high-pitched noise proportional to engine speed | "NOISE" listed below "Turbocharger Noise" Flowchart w/ DPF: () w/o DPF: () |

| Whining noise | Relatively low-pitched noise compared to whistling noise | ||

| Oil leak | External oil leak | Oil leak on surface of turbocharger visible from outside of turbocharger | "OIL LEAK AND WHITE SMOKE" listed below "Turbocharger Oil Leak and White Smoke" Flowchart w/ DPF: () w/o DPF: () |

| Internal oil leak | Oil leak from inside of bearing housing to inside of either compressor housing or turbine housing through seal ring | ||

| White smoke | Oil smoke | Oil smoke is emitted from exhaust pipe | |

| Unburned fuel smoke | Unburned fuel smoke is emitted from exhaust pipe | ||

| Black smoke | Black smoke is emitted from exhaust pipe | "BLACK SMOKE" listed below "Black Smoke Emitted" Flowchart w/ DPF: () w/o DPF: () | |

| Lack of power or hesitation | Vehicle does not reach target speed | "LACK OF POWER AND HESITATION" listed below "Lack of Power or Hesitation" Flowchart w/ DPF: () w/o DPF: () | |

| Poor acceleration | |||

| Shock during acceleration | |||

| MIL turns on (DTC) | P0046 | Control Solenoid Circuit Range / Performance | Diagnostic Trouble Code Chart w/ DPF: () w/o DPF: () |

| P0047 | Boost Control "A" Circuit Low | ||

| P0048 | Boost Control "A" Circuit High | ||

| P004B | Boost control solenoid "B" circuit Range / Performance | ||

| P004C | Boost control solenoid "B" circuit low | ||

| P004D | Boost control solenoid "B" circuit high | ||

| P00AF *1 | Boost control "A" module performance | ||

| P00B0 *1 | Boost control "B" module performance | ||

| P0299 | Underboost | ||

| P1251 | Overboost Condition (Too High) | ||

| P1258 *1 | Position sensor circuit range/performance bank 2 sensor 1 | ||

| P1259 *1 | Position sensor low bank 2 sensor 1 | ||

| P1260 *1 | Position sensor high bank 2 sensor 1 | ||

| P1262 *1 | Position sensor low bank 2 sensor 2 | ||

| P1263 *1 | Position sensor high bank 2 sensor 2 | ||

| P2563 *1 | Position Sensor "A" Circuit Range/Performance | ||

| P2564 | Position Sensor "A" Circuit Low | ||

| P2565 | Position Sensor "A" Circuit High | ||

| P2588 | Position Sensor "B" Circuit Low | ||

| P2589 | Position Sensor "B" Circuit High | ||

- HINT:

| NOISE |

| Probable Cause | Probable Failed Component |

| Turbine shaft imbalance | Turbocharger |

| Leakage from intake line | Intake line |

| Gear noise (Mistaken for turbocharger noise) | Gear inside engine Transmission gear Vacuum pump gear |

- HINT:

- It is easy to confirm whether the turbocharger is the cause of the noise or not, and confirming this before inspecting the turbocharger or removing it from the engine is an effective way to reduce troubleshooting time.

Connect the intelligent tester to the DLC3.

Start the engine and warm it up.

Turn the tester on.

Enter the following menus: Powertrain / Engine / Active Test / Activate the VN Turbo Open.

- HINT:

- This Active Test function operates both the turbocharger actuators (bank 1 and bank 2) at the same time.

Perform the Active Test and rev the engine up several times.

Check whether the noise is reduced or not compared with the noise heard when the Active Test is not performed.

| Result | Cause of Noise |

| The noise is reduced (or disappears) | Turbocharger |

| The noise does not change | Not turbocharger (other parts) |

- HINT:

- Refer to the "Turbocharger Noise" flowchart.

| OIL LEAK AND WHITE SMOKE |

| Oil Leak Type | Description | Main Trouble Area |

| Internal oil leak (White smoke) | Oil leak from bearing housing to either compressor housing (intake side) or turbine housing (exhaust side) through seal rings. This type of oil leak is not visible from outside of turbocharger. If oil leak occurs from turbine side seal, large amount of white smoke is emitted from exhaust pipe. | Compressor side seal ring Turbine side seal ring Clogging of oil drain Shaft breakage Shaft or bearing seizure Compressor impeller damage |

| External oil leak | Oil leak from inside of turbocharger to outside of turbocharger. Includes oil leaks visible from outside of turbocharger. | FIPG sealing part Oil pipe flange Oil pipe union Hose connection of intake pipe |

| *1 | Compressor Housing | *2 | Seal Ring |

| *3 | Compressor Inlet | *4 | Compressor Impeller |

| *5 | Bearing Housing | *6 | Turbine Shaft |

| *7 | Oil Drain (Outlet) | *8 | FIPG Sealing Part |

| *9 | Turbine Housing | *10 | Turbine Wheel |

| *a | DC Motor Type Turbocharger (No. 1) | *b | Internal oil leak to compressor housing |

| *c | Internal oil leak to turbine housing | - | - |

- HINT:

| BLACK SMOKE |

Malfunctions are classified into 2 types as shown below.

| Malfunction | Main Fault |

| Intake air volume shortage | Insufficient mass airflow due to, for example, excessively low boost pressure, which results in fuel injection volume being relatively excessive with respect to mass airflow. |

| Excessive injection volume | Excessive injection volume or incorrect injection timing due to fuel system trouble. |

Main Components Related to Black Smoke:

| Possible Faulty Component | Main Fault |

| Turbocharger | Abnormally low boost pressure |

| Intake system | Leakage between turbocharger and intake manifold |

| Fuel system | Excessive fuel injection volume Incorrect fuel injection timing |

| EGR valve | Stuck or does not close completely |

| Diesel throttle | Stuck or does not move smoothly |

- HINT:

- The components listed above are only the main ones. Not all the components potentially related to black smoke are listed. For details regarding the troubleshooting of black smoke, refer to the "Black Smoke Emitted" flowchart.

Relation between Turbocharger and Black Smoke:

If the boost pressure is lower than normal due to a turbocharger failure, black smoke may occur due to a lack of mass airflow. However, abnormally low boost pressure can be caused by the failure of various components such as intake lines, the EGR valve, etc. Therefore, do not assume that the turbocharger is the cause of abnormally low boost pressure, but check all the components possibly related to abnormally low boost pressure. Components related to abnormal boost pressure are shown in a chart listed in the On-vehicle Inspection for the Intake System (). For simple and effective troubleshooting, refer to the chart before starting troubleshooting.

| LACK OF POWER AND HESITATION |

Malfunctions are classified into 2 types as shown below.

| Malfunction | Main Fault |

| Intake air volume shortage | Insufficient mass airflow due to, for example, excessively low boost pressure, which results in fuel injection volume being restricted. |

| Abnormal injection volume | Abnormal injection volume or timing due to fuel system trouble. |

Main Components Related to Lack of Power and Hesitation:

| Possible Faulty Component | Main Fault |

| Turbocharger | Abnormal boost pressure VN does not move smoothly |

| Intake system | Leakage between turbocharger and intake manifold Clogging or blockage of intake line |

| Fuel system | Abnormal injection volume Incorrect fuel injection timing |

| EGR valve | Stuck or does not close completely |

| Diesel throttle | Stuck or does not move smoothly |

| Exhaust system | Clogging of exhaust line |

- HINT:

Relation between Turbocharger and Abnormal Boost Pressure:

If the boost pressure is lower than normal due to a turbocharger failure, a lack of power could occur due to an intake air volume shortage. However, abnormal boost pressure can be caused by the failure of various components such as intake lines, the EGR valve, etc. Therefore, do not assume that the turbocharger is the cause of abnormal boost pressure, but check all the components possibly related to abnormal boost pressure. Components related to abnormal boost pressure are shown in a chart listed in the On-vehicle Inspection for the Intake System (). For simple and effective troubleshooting, refer to the chart before starting troubleshooting.

| MIL TURNS ON |

If a DTC related to a turbocharger malfunction is stored, refer to the troubleshooting section for each DTC.

| BRIEF OUTLINE OF TURBOCHARGER OPERATION AND CONSTRUCTION |

A turbocharger is a component used to supply a larger air volume to the cylinders by recovering exhaust gas energy using a turbine coaxially connected to a compressor.

Principle of Turbocharging:

Boost pressure is proportional to turbocharger speed, because the intake air is accelerated by centrifugal force generated by the rotation of the compressor and the increased kinetic energy, i.e. the velocity of the intake air, is converted to pressure energy by the diffuser located around the outlet of the compressor impeller. The compressor is driven by the turbine connected coaxially by the turbine shaft. The turbine is driven by exhaust gas energy. Therefore, when the turbocharger begins boosting the intake air, a larger air volume is supplied to the cylinders and more fuel can be injected. As a result, more exhaust energy will be available and the turbocharger boost increases.

| *1 | Compressor | *2 | Turbine |

| *3 | Air Cleaner | *4 | Exhaust Manifold |

| *5 | Intake Manifold | *6 | Intercooler (w/ Intercooler) |

| *7 | Diffuser | *8 | Compressor |

| *a | See HINT below | *b | Intake Airflow |

- HINT:

Boost Pressure Control:

The amount of energy the turbine can obtain from the exhaust gas is proportional to the expansion ratio, which is defined as the ratio of the turbine inlet exhaust gas pressure to the pressure at the turbine outlet.

To control boost pressure, a Variable Nozzle (VN) is used just upstream of the turbine wheel inlet, and controls the expansion ratio. If the VN is closed, the gap between neighboring vanes is narrowed and the turbine inlet exhaust gas pressure, and correspondingly the expansion ratio, increases. Therefore, when the VN is closed, the turbine receives more energy, and the turbine speed and boost pressure increase. On the other hand, if the VN is opened, the turbine inlet exhaust gas pressure decreases, and the turbine speed and boost pressure decrease. The VN is actuated by a DC motor.

w/o DPF: The ECM controls the VN opening angle through the turbo motor driver in accordance with the engine condition.

When a high engine power is required, the actuation rod is moved by the actuator to close the VN and boost pressure increases.

| *1 | VN (Variable Nozzle) | *2 | Turbine Wheel |

| *3 | Narrow Gap | *4 | Wide Gap |

| *a | VN Closed | *b | VN Opened |

| *c | Exhaust Gas Flow | - | - |

- HINT:

- If the VN becomes stuck open, the necessary boost pressure will not be available. If the VN becomes stuck closed, overboost will occur.

Mechanical Construction of Turbocharger:

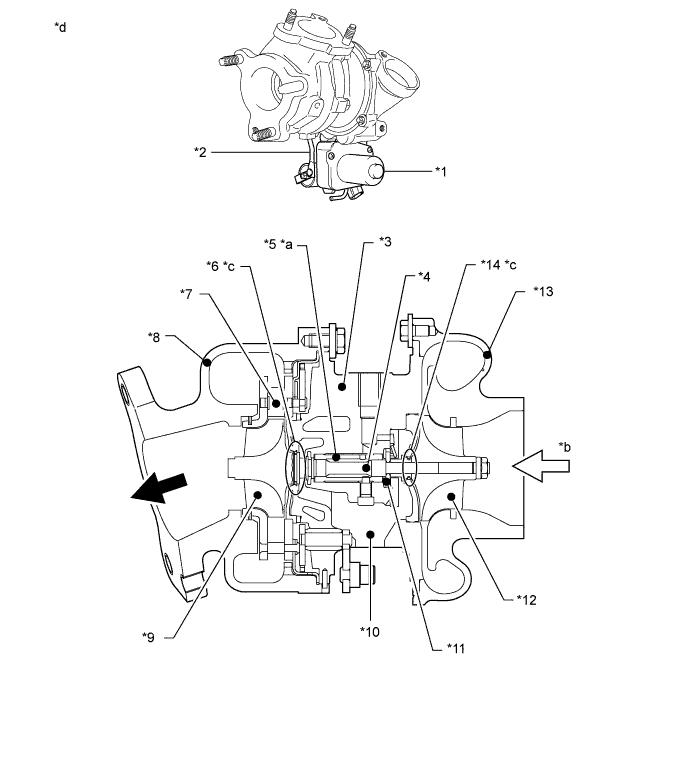

| *1 | VN Actuator (DC Motor) | *2 | VN Actuating Rod |

| *3 | Bearing Housing | *4 | Turbine Shaft |

| *5 | Radial Bearing | *6 | Turbine Side Seal Ring |

| *7 | VN (Variable Nozzle) | *8 | Turbine Housing |

| *9 | Turbine Wheel | *10 | Oil Drain |

| *11 | Thrust Bearing | *12 | Compressor Impeller |

| *13 | Compressor Housing | *14 | Compressor Side Seal Ring |

| *a | See HINT below | *b | See HINT below |

| *c | See HINT below | *d | DC Motor Type Turbocharger (No. 1) |

| Exhaust Gas Flow |  | Intake Airflow |

- HINT: