Land Cruiser URJ200 URJ202 GRJ200 VDJ200 - 1UR-FE ENGINE MECHANICAL

ENGINE UNIT - INSPECTION

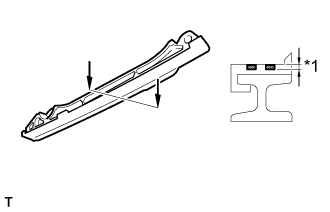

| 1. INSPECT CYLINDER HEAD SET BOLT |

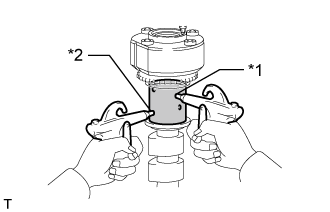

Using a vernier caliper, measure the length of the cylinder head set bolt from the seat to the end.

- Standard length:

- 141.3 to 142.7 mm (5.56 to 5.62 in.)

- Maximum length:

- 143.7 mm (5.66 in.)

| *1 | Measurement Length |

| *2 | Distance |

If the length is more than the maximum, replace the cylinder head set bolt.

Using a vernier caliper, measure the diameter of the elongated threads around the point indicated in the illustration.

- Distance:

Item Specified Condition Intake side bolt 103 mm (4.06 in.) Exhaust side bolt 108 mm (4.25 in.)

- Standard diameter:

- 10.85 to 11.00 mm (0.427 to 0.433 in.)

- Minimum diameter:

- 10.60 mm (0.417 in.)

If the diameter is less than the minimum, replace the cylinder head set bolt.

- HINT:

- If a visual check reveals no excessively thin areas, check the area of the bolt around the point indicated in the illustration and find the area that has the smallest diameter.

| 2. INSPECT NO. 1 VALVE ROCKER ARM SUB-ASSEMBLY |

Turn the roller by hand to check that it turns smoothly.

If the roller does not turn smoothly, replace the No. 1 valve rocker arm sub-assembly.

| 3. INSPECT VALVE LASH ADJUSTER ASSEMBLY |

- NOTICE:

Place the valve lash adjuster into a container full of new engine oil.

| *1 | Taper Part |

| *2 | Plunger |

| *3 | Low Pressure Chamber |

| *4 | Check Ball |

| *5 | High Pressure Chamber |

Insert the tip of SST into the valve lash adjuster plunger and use the tip to press down on the check ball inside the plunger.

- SST

- 09276-75010

Squeeze SST and the valve lash adjuster together to move the plunger up and down 5 to 6 times.

Check the movement of the plunger and bleed air.

- OK:

- Plunger moves up and down.

- NOTICE:

- When bleeding high-pressure air from the compression chamber, make sure that the tip of SST is actually pressing the check ball as shown in the illustration. If the check ball is not pressed, air will not bleed.

After bleeding the air, remove SST. Then try to quickly and firmly press the plunger with your fingers.

- OK:

- Plunger can be pressed 3 times.

If the plunger can still be compressed after pressing it 3 times, replace the valve lash adjuster assembly with a new one.

| 4. INSPECT CAMSHAFT SUB-ASSEMBLY |

Inspect the camshaft runout.

Place the camshaft on V-blocks.

Using a dial indicator, measure the circle runout at the center journal.

- Maximum circle runout:

- 0.04 mm (0.00157 in.)

If the circle runout is more than the maximum, replace the camshaft sub-assembly.

- HINT:

- Check the oil clearance after replacing the camshaft.

Using a micrometer, measure the cam lobe height.

- Standard Cam Lobe Height:

Item Specified Condition Intake 44.291 to 44.441 mm (1.744 to 1.750 in.) Exhaust 44.196 to 44.346 mm (1.740 to 1.746 in.)

- Minimum Cam Lobe Height:

Item Specified Condition Intake 44.241 mm (1.742 in.) Exhaust 44.146 mm (1.738 in.)

If the cam lobe height is less than the minimum, replace the camshaft sub-assembly.

Using a micrometer, measure the journal diameter.

- Standard Journal Diameter:

Item Specified Condition No. 1 journal 29.956 to 29.970 mm (1.1793 to 1.1799 in.) Other journals 25.959 to 25.975 mm (1.0220 to 1.0226 in.)

If the journal diameter is not as specified, check the oil clearance.

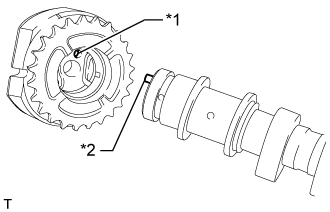

| 5. INSPECT CAMSHAFT TIMING GEAR ASSEMBLY |

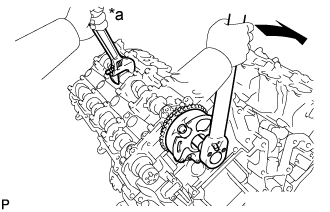

Install the camshaft bearing cap ().

- HINT:

- Only install the intake camshaft.

Install the camshaft housing ().

- HINT:

- Do not use seal packing when installing the camshaft housing as the installation is temporary.

Apply a light coat of engine oil to the camshaft and camshaft timing gear.

Using the hexagonal portion of the camshaft, align the knock pin of the camshaft with the pin hole of the camshaft timing gear and install the camshaft timing gear.

| *1 | Knock Pin |

| *2 | Pin Hole |

- NOTICE:

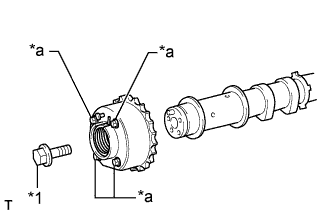

| *1 | Flange Bolt |

| *2 | Straight Pin |

| *a | Do not remove |

Apply a light coat of engine oil to the threads and under the head of the bolt.

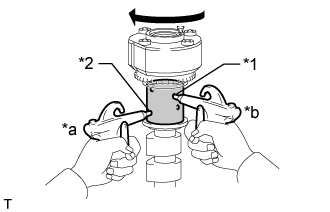

Using a wrench to hold the hexagonal portion of the camshaft, install the camshaft timing gear flange bolt.

- Torque:

- 100 N*m{ 1020 kgf*cm, 74 ft.*lbf}

| *a | Hold |

| Turn |

Remove the camshaft bearing cap ().

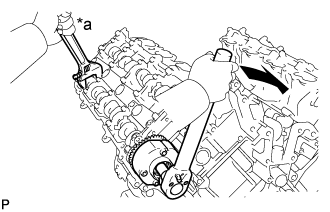

Check the lock of the camshaft timing gear.

Clamp the camshaft in a vise and confirm that the camshaft timing gear is locked.

- NOTICE:

- Be careful not to damage the camshaft.

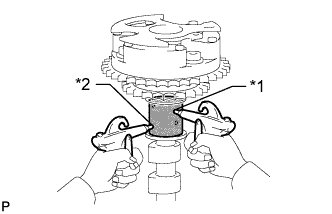

Release the lock pin.

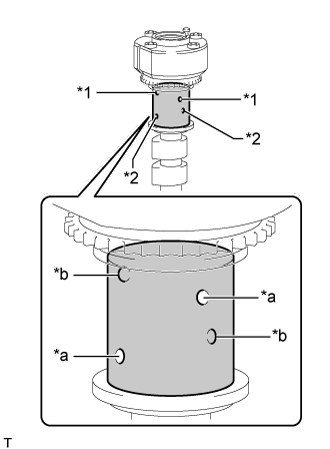

| *1 | Advance Side Path |

| *2 | Retard Side Path |

| *a | Open |

| *b | Close |

| Vinyl Tape |

Clean the cam journal with non-residue solvent.

Cover the 4 oil paths of the cam journal with vinyl tape as shown in the illustration.

Break through the tape over the advance side path. Then break through the tape over the retard side path on the opposite side of the advanced side path as shown in the illustration.

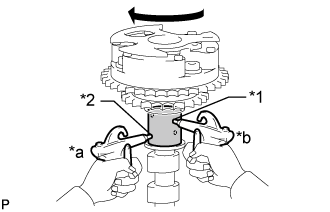

Apply compressed air at approximately 200 kPa (2.0 kgf/cm2, 29 psi) to the two paths accessible through the holes in the tape.

| *1 | Advance Side Path |

| *2 | Retard Side Path |

- NOTICE:

- Cover the paths with a piece of cloth when applying pressure to keep oil from splashing.

Check that the camshaft timing gear revolves in the advance direction when reducing the air pressure applied to the retard side path.

| *1 | Advance Side Path |

| *2 | Retard Side Path |

| *a | Decompress |

| *b | Hold Pressure |

- HINT:

- This operation releases the lock pin which holds the timing gear in the most retarded position.

When the camshaft timing gear reaches the most advanced position, release the air pressure from the retard side path and advance side path in that order.

- NOTICE:

- Do not release the air pressure from the advance side path first. The gear may abruptly shift in the retard direction and break the lock pin.

Check for smooth rotation.

Turn the camshaft timing gear within its movable range (21°) 2 or 3 times, but do not turn it to the most retarded position. Make sure that the gear turns smoothly.

- NOTICE:

- Do not use air pressure to perform the smooth rotation check.

Check the lock at the most retarded position.

Confirm that the camshaft timing gear becomes locked at the most retarded position.

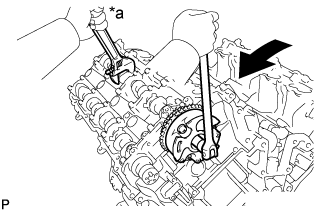

Install the camshaft bearing cap ().

- HINT:

- Only install the intake camshaft.

Install the camshaft housing ().

- HINT:

- Do not use seal packing when installing the camshaft housing as the installation is temporary.

Hold the hexagonal portion of the camshaft with a wrench and loosen the flange bolt.

| *a | Hold |

| Turn |

Remove the camshaft bearing cap ().

Remove the flange bolt and camshaft timing gear.

| 6. INSPECT CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY |

Install the camshaft bearing cap ().

- HINT:

- Only install the exhaust camshaft.

Install the camshaft housing ().

- HINT:

- Do not use seal packing when installing the camshaft housing as the installation is temporary.

Apply a light coat of engine oil to the camshaft and camshaft timing exhaust gear.

Using the hexagonal portion of the camshaft, align the knock pin of the camshaft with the pin hole of the camshaft timing exhaust gear and install the camshaft timing exhaust gear.

| *1 | Pin Hole |

| *2 | Knock Pin |

- NOTICE:

| *1 | Flange Bolt |

| *a | Do not remove |

Apply a light coat of engine oil to the threads and under the head of the bolt.

Using a wrench to hold the hexagonal portion of the camshaft, install the camshaft timing exhaust gear flange bolt.

- Torque:

- 100 N*m{ 1020 kgf*cm, 74 ft.*lbf}

| *a | Hold |

| Turn |

Remove the camshaft bearing cap ().

Check the camshaft timing exhaust gear lock.

Make sure that the camshaft timing exhaust gear is locked.

Release the lock pin.

| *1 | Advance Side Path |

| *2 | Retard Side Path |

| *a | Open |

| *b | Close |

| Vinyl Tape |

Cover the 4 oil paths of the cam journal with vinyl tape as shown in the illustration.

Break through the tape over the advance side path. Then break through the tape over the retard side path on the opposite side of the advanced side path as shown in the illustration.

Apply compressed air at approximately 200 kPa (2.0 kgf/cm2, 29 psi) to the two paths accessible through the holes in the tape (the advance side path and retard side path).

| *1 | Advance Side Path |

| *2 | Retard Side Path |

- NOTICE:

- Cover the paths with a piece of cloth when applying pressure to keep oil from splashing.

Check that the camshaft timing exhaust gear turns in the retard direction when reducing the air pressure applied to the advance side path.

| *1 | Advance Side Path |

| *2 | Retard Side Path |

| *a | Hold Pressure |

| *b | Decompress |

- HINT:

- The lock pin is released and the camshaft timing exhaust gear turns in the retard direction.

When the camshaft timing exhaust gear moves to the most retarded position, release the air pressure from the advance side path, and then release the air pressure from the retard side path.

- NOTICE:

- Be sure to release the air pressure from the advance side path first. If the air pressure of the retard side path is released first, the camshaft timing exhaust gear may abruptly shift in the advance direction and break the lock pin or other parts.

Check for smooth rotation.

Turn the camshaft timing exhaust gear within its movable range (18.5°) 2 or 3 times, but do not turn it to the most advanced position. Make sure that the gear turns smoothly.

- NOTICE:

- When the air pressure is released from the advance side path and then from the retard side path, the gear automatically returns to the most advanced position, due to the advance assist spring operation, and locks. Gradually release the air pressure from the retard side path before performing the smooth rotation check.

Check the lock at the most advanced position.

Make sure that the camshaft timing exhaust gear becomes locked at the most advanced position.

Install the camshaft bearing cap ().

- HINT:

- Only install the exhaust camshaft.

Install the camshaft housing ().

- HINT:

- Do not use seal packing when installing the camshaft housing as the installation is temporary.

Hold the hexagonal portion of the camshaft with a wrench and loosen the flange bolt.

| *a | Hold |

| Turn |

Remove the camshaft bearing cap ().

Remove the flange bolt and camshaft timing exhaust gear.

| 7. INSPECT NO. 1 CHAIN SUB-ASSEMBLY |

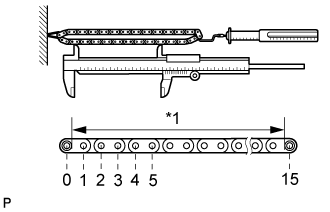

Using a spring scale, pull the chain with a force of 147 N (15 kgf, 33.1 lbf) as shown in the illustration.

| *1 | Measurement Area |

Using a vernier caliper, measure the length of 15 pins.

- Maximum chain elongation:

- 136.9 mm (5.39 in.)

- HINT:

- Perform the measurement at 3 random places.

If the elongation is more than the maximum, replace the No. 1 chain sub-assembly.

| 8. INSPECT NO. 2 CHAIN SUB-ASSEMBLY |

Using a spring scale, pull the chain with a force of 147 N (15 kgf, 33.1 lbf).

Using a vernier caliper, measure the length of 15 pins.

- Maximum chain elongation:

- 137.6 mm (5.42 in.)

- HINT:

- Perform the measurement at 3 random places.

If the elongation is more than the maximum, replace the No. 2 chain sub-assembly.

| 9. INSPECT CRANKSHAFT TIMING SPROCKET RH |

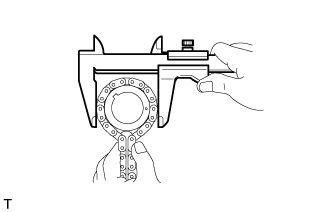

Wrap the chain around the sprocket.

Using a vernier caliper, measure the sprocket diameter with the chain.

- Minimum sprocket diameter (with chain):

- 61.4 mm (2.42 in.)

- HINT:

- The vernier caliper must contact the chain rollers for the measurement.

If the diameter is less than the minimum, replace the chain and crankshaft timing sprocket RH.

| 10. INSPECT CRANKSHAFT TIMING SPROCKET LH |

Wrap the chain around the sprocket.

Using a vernier caliper, measure the sprocket diameter with the chain.

- Minimum sprocket diameter (with chain):

- 61.4 mm (2.42 in.)

- HINT:

- The vernier caliper must contact the chain rollers for the measurement.

If the diameter is less than the minimum, replace the chain and crankshaft timing sprocket LH.

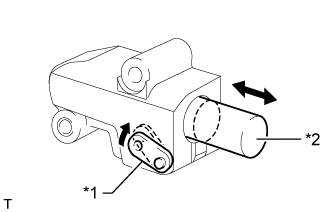

| 11. INSPECT NO. 1 CHAIN TENSIONER ASSEMBLY |

Move the stopper plate upward to release the lock.

| *1 | Stopper Plate |

| *2 | Plunger |

Push the plunger and check that it moves smoothly.

If necessary, replace the No. 1 chain tensioner assembly.

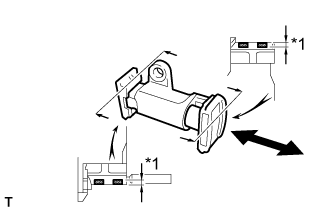

| 12. INSPECT NO. 2 CHAIN TENSIONER ASSEMBLY |

Check that the plunger moves smoothly.

Measure the worn depth of the chain tensioner.

- Maximum depth:

- 0.9 mm (0.0354 in.)

| *1 | Depth |

If the depth is more than the maximum, replace the No. 2 chain tensioner assembly.

| 13. INSPECT NO. 3 CHAIN TENSIONER ASSEMBLY |

Check that the plunger moves smoothly.

Measure the worn depth of the chain tensioner.

- Maximum depth:

- 0.9 mm (0.0354 in.)

| *1 | Depth |

If the depth is more than the maximum, replace the No. 3 chain tensioner assembly.

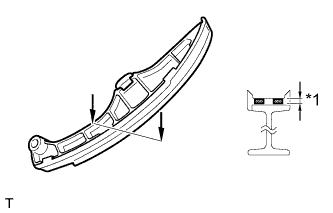

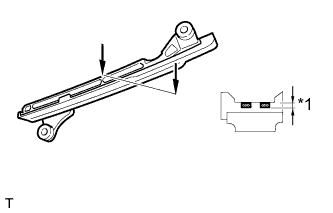

| 14. INSPECT CHAIN TENSIONER SLIPPER LH |

Measure the worn depth of the chain tensioner slipper.

- Maximum depth:

- 1.0 mm (0.0394 in.)

| *1 | Depth |

If the depth is more than the maximum, replace the chain tensioner slipper LH.

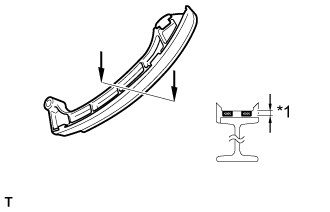

| 15. INSPECT CHAIN TENSIONER SLIPPER RH |

Measure the worn depth of the chain tensioner slipper.

- Maximum depth:

- 1.0 mm (0.0394 in.)

| *1 | Depth |

If the depth is more than the maximum, replace the chain tensioner slipper RH.

| 16. INSPECT NO. 1 CHAIN VIBRATION DAMPER LH |

Measure the worn depth of the chain vibration damper.

- Maximum depth:

- 1.0 mm (0.0394 in.)

| *1 | Depth |

If the depth is more than the maximum, replace the No. 1 chain vibration damper LH.

| 17. INSPECT NO. 1 CHAIN VIBRATION DAMPER RH |

Measure the worn depth of the chain vibration damper.

- Maximum depth:

- 1.0 mm (0.0394 in.)

| *1 | Depth |

If the depth is more than the maximum, replace the No. 1 chain vibration damper RH.

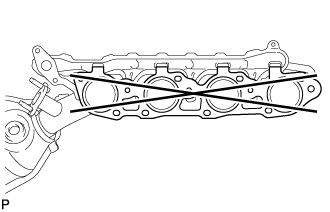

| 18. INSPECT EXHAUST MANIFOLD ASSEMBLY LH |

Using a precision straightedge and feeler gauge, measure the warpage of the contact surface of the cylinder head.

- Maximum warpage:

- 0.7 mm (0.0276 in.)

If the warpage is more than the maximum, replace the exhaust manifold assembly LH.

| 19. INSPECT EXHAUST MANIFOLD ASSEMBLY RH |

Using a precision straightedge and feeler gauge, measure the warpage of the contact surface of the cylinder head.

- Maximum warpage:

- 0.7 mm (0.0276 in.)

If the warpage is more than the maximum, replace the exhaust manifold assembly RH.