INSPECTION PROCEDURE

CHECK INJECTOR COMPENSATION CODE

REGISTER INJECTOR COMPENSATION CODE AND PERFORM PILOT QUANTITY LEARNING

TAKE SNAPSHOT DURING IDLING AND 4000 RPM (PROCEDURE 3)

READ VALUE USING GTS (INJECTION FEEDBACK VAL #1 TO #8 AND INJECTION VOLUME)

PERFORM ACTIVE TEST USING GTS (CHECK THE CYLINDER COMPRESSION)

CHECK CYLINDER COMPRESSION PRESSURE

PERFORM PILOT QUANTITY LEARNING (DETAIL)

READ VALUE USING GTS (INJECTION FEEDBACK VAL #1 TO #8)

REPLACE INJECTOR ASSEMBLY OF MALFUNCTIONING CYLINDER

READ VALUE USING GTS (INJECTION VOLUME)

REPLACE INJECTOR ASSEMBLIES OF ALL CYLINDERS

CLEAN FUEL FILTER CASE AND REPLACE FUEL FILTER

BLEED AIR FROM FUEL SYSTEM

REGISTER INJECTOR COMPENSATION CODE AND PERFORM PILOT QUANTITY LEARNING

CHECK AND REPLACE ENGINE ASSEMBLY

PERFORM ACTIVE TEST USING GTS (TEST THE FUEL LEAK)

INSPECT COMMON RAIL ASSEMBLY (FOR BANK 2) (PRESSURE DISCHARGE VALVE)

INSPECT CLOGGED FUEL PIPE

REPAIR OR REPLACE CLOGGED FUEL LINE

REPLACE COMMON RAIL ASSEMBLY (FOR BANK 2) (PRESSURE DISCHARGE VALVE)

BLEED AIR FROM FUEL SYSTEM

READ VALUE USING GTS (COMMON RAIL PRESSURE AND TARGET COMMON RAIL PRESSURE)

REPLACE FUEL SUPPLY PUMP ASSEMBLY (SUCTION CONTROL VALVE)

BLEED AIR FROM FUEL SYSTEM

PERFORM SUPPLY PUMP INITIALIZATION

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

ECD SYSTEM (w/ DPF) - Fuel Injection System

INSPECTION PROCEDURE

After replacing the ECM, the new ECM needs registration () and initialization ().

After replacing the fuel supply pump assembly, the ECM needs initialization ().

After replacing an injector assembly, the ECM needs registration ().

| 1.CHECK INJECTOR COMPENSATION CODE |

Check the injector compensation code ().

Result| Result | Proceed to |

| Except below | A |

| Compensation codes of the installed injector assemblies are the same as the compensation codes registered in the ECM | B |

| 2.REGISTER INJECTOR COMPENSATION CODE AND PERFORM PILOT QUANTITY LEARNING |

Register the injector compensation codes ().

Perform the injector pilot quantity learning ().

| 3.TAKE SNAPSHOT DURING IDLING AND 4000 RPM (PROCEDURE 3) |

Connect the GTS to the DLC3.

Start the engine and turn the GTS on.

Enter the following menus: Engine and ECT / Data List / All Data.

Take a snapshot of the Data List items.

A snapshot can be used to compare vehicle data from the time of the malfunction to normal data and is very useful for troubleshooting. The data in the list below is that of a normal vehicle, but as the data varies between individual vehicles, this data should only be used for reference.

Check the Data List at idling and at 4000 rpm with no load after the engine is warmed up.

| 4.READ VALUE USING GTS (INJECTION FEEDBACK VAL #1 TO #8 AND INJECTION VOLUME) |

Check Injection Feedback Val #1 to #8 and Injection Volume in the snapshot taken in procedure 3 when the engine was idling and at 4000 rpm with no load.

Result| Result | Proceed to |

| Injection Feedback Val for at least one cylinder is more than 3.0 mm3/st | A |

| Injection Volume is 9 mm3/st or less at 4000 rpm | B |

| Except above | C |

When there is a problem with the operation of an injector assembly due to foreign matter in the inside of the injector assembly, etc., the fuel injection volume decreases. As a result, the ECM gives instructions to increase the fuel injection volume, which causes Injection Feedback Val to increase.

The ECM controls the system so that the sum of Injection Feedback Val for all of the cylinders is approximately 0 mm3/st. Even if the value of Injection Feedback Val for a cylinder is less than -3.0 mm3/st (-3.0 mm3/st is the lowest normal value), as long as the value of Injection Feedback Val for each of the other cylinders is 3.0 mm3/st or less, the injector assemblies are not malfunctioning.

| 5.PERFORM ACTIVE TEST USING GTS (CHECK THE CYLINDER COMPRESSION) |

- Use this Active Test to help determine whether a cylinder has compression loss or not.

Connect the GTS to the DLC3.

Start the engine and turn the GTS on.

Enter the following menus: Engine and ECT / Active Test / Check the Cylinder Compression / Data List / Compression / Engine Speed of Cyl #1 to #8.

Check the engine speed during the Active Test.

Result| Result | Proceed to |

| Except below | A |

| The values of Engine Speed Cyl #1 to #8 are within +/-10 rpm of each other. | B |

- When cranking, if the speed of a cylinder is approximately 100 rpm more than the other cylinders, there is probably a complete loss of compression in that cylinder.

| 6.CHECK CYLINDER COMPRESSION PRESSURE |

Check the cylinder compression pressure ().

- When compression is low, there may be cracks in the piston or the injector assembly may be installed improperly.

| 7.PERFORM PILOT QUANTITY LEARNING (DETAIL) |

Perform the injector pilot quantity learning (Detail) ().

| 8.READ VALUE USING GTS (INJECTION FEEDBACK VAL #1 TO #8) |

Connect the GTS to the DLC3.

Turn the engine switch on (IG) and turn the GTS on.

Start the engine and warm it up.

Enter the following menus: Engine and ECT / Data List / Injection Feedback Val #1 to #8.

Read the values.

- Standard:

| GTS Display | Engine Condition* | Normal Value |

| Injection Feedback Val #1 to #8 | Idling | -3.0 mm3/st to 3.0 mm3/st |

- *: The A/C switch and all accessory switches should be off, the engine coolant temperature should be 75°C (167°F) or more and the engine should be idled for 1 minute or more.

Result| Result | Proceed to |

| Injection Feedback Val for at least one cylinder is more than 3.0 mm3/st | A |

| Except above | B |

When there is a problem with the operation of an injector assembly due to foreign matter in the inside of the injector assembly, etc., the fuel injection volume decreases. As a result, the ECM gives instructions to increase the fuel injection volume, which causes Injection Feedback Val to increase.

The ECM controls the system so that the sum of Injection Feedback Val for all of the cylinders is approximately 0 mm3/st. Even if the value of Injection Feedback Val for a cylinder is less than -3.0 mm3/st (-3.0 mm3/st is the lowest normal value), as long as the value of Injection Feedback Val for each of the other cylinders is 3.0 mm3/st or less, the injector assemblies are not malfunctioning.

| 9.REPLACE INJECTOR ASSEMBLY OF MALFUNCTIONING CYLINDER |

Replace the injector assembly of the malfunctioning cylinder ().

When replacing the injector assembly for a cylinder, always be sure to use a new injection pipe.

Follow the procedure in the repair manual and temporarily install the injection pipes and nozzle leakage pipe, and then correctly position the injector assemblies. After that, tighten parts according to the torque specifications.

If the installation procedure is not performed correctly, injector assemblies may become out of position, which may cause the injector assemblies to deteriorate, resulting in malfunctions.

If an injector assembly deteriorates and malfunctions, other problems such as knocking, rough idle, etc. may occur.

If an injector assembly becomes out of position, it is possible that the seal between the injector assembly and injection pipe may become incomplete, resulting in a fuel leak.

| 10.READ VALUE USING GTS (INJECTION VOLUME) |

Check Injection Volume in the snapshot taken in procedure 3 when the engine was idling.

Result| Result | Proceed to |

| Injection Volume while idling after engine warm up is 13 mm3/st or more | A |

| Except above | B |

- Check that PM forced regeneration is not being performed.

- The idling speed during PM forced regeneration is 650 to 750 rpm (with the shift lever in neutral).

| 11.REPLACE INJECTOR ASSEMBLIES OF ALL CYLINDERS |

Replace the injector assemblies of all cylinders ().

When replacing the injector assembly for a cylinder, always be sure to use a new injection pipe.

Follow the procedure in the repair manual and temporarily install the injection pipes and nozzle leakage pipe, and then correctly position the injector assemblies. After that, tighten parts according to the torque specifications.

If the installation procedure is not performed correctly, injector assemblies may become out of position, which may cause the injector assemblies to deteriorate, resulting in malfunctions.

If an injector assembly deteriorates and malfunctions, other problems such as knocking, rough idle, etc. may occur.

If an injector assembly becomes out of position, it is possible that the seal between the injector assembly and injection pipe may become incomplete, resulting in a fuel leak.

| 12.CLEAN FUEL FILTER CASE AND REPLACE FUEL FILTER |

Clean the fuel filter case and replace the fuel filter.

- Be sure to clean the inside of the fuel filter case as the fuel injectors may not operate properly if the fuel filter is installed with foreign matter remaining inside the fuel filter case.

| 13.BLEED AIR FROM FUEL SYSTEM |

Bleed the air from the fuel system ().

Perform PM forced regeneration ().

- When fuel lines are disconnected, air may enter the fuel lines, leading to engine starting trouble. Therefore, perform forced regeneration and bleed the air from the fuel lines.

| 14.REGISTER INJECTOR COMPENSATION CODE AND PERFORM PILOT QUANTITY LEARNING |

Register the injector compensation codes ().

Perform the injector pilot quantity learning ().

| 15.CHECK AND REPLACE ENGINE ASSEMBLY |

Check and replace the engine assembly.

| 16.PERFORM ACTIVE TEST USING GTS (TEST THE FUEL LEAK) |

Connect the GTS to the DLC3.

Turn the engine switch on (IG) and turn the GTS on.

Enter the following menus: Engine and ECT / Active Test / Test the Fuel Leak / Data List / Common Rail Pressure, Target Common Rail Pressure, and Target Pump SCV Current.

Take a snapshot with the GTS during the Active Test.

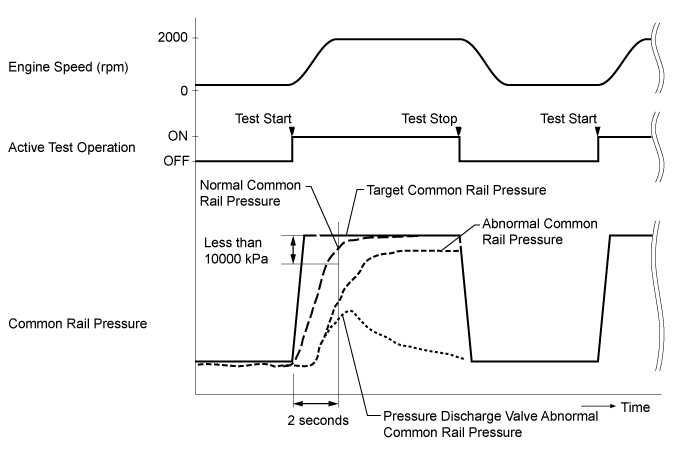

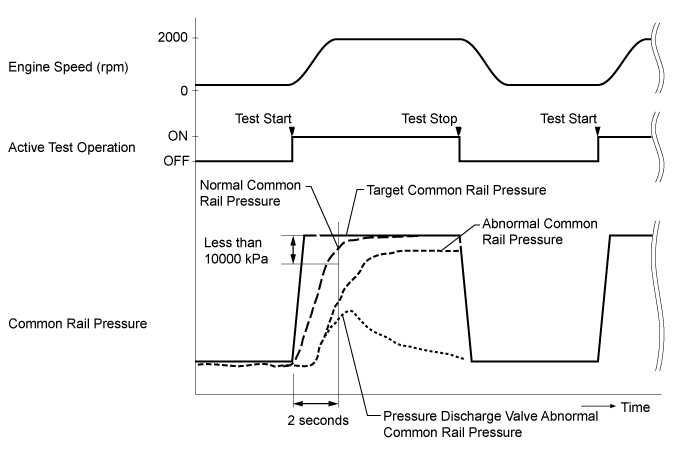

Measure the difference between the target fuel pressure (Target Common Rail Pressure) and the actual fuel pressure (Common Rail Pressure) when the "Test the Fuel Leak" Active Test is performed.

- In order to obtain an exact measurement, perform the Active Test 5 times and measure the difference once each time the Active Test is performed.

- OK:

- The difference between the target fuel pressure and the actual fuel pressure 2 seconds after the Active Test starts is less than 10000 kPa (102.0 kgf/cm2, 1451 psi).

Result| Result | Proceed to |

| NG | A |

| OK* | B |

- *: Even when the results of the Active Test are normal, take a snapshot of vehicle data when the vehicle is accelerating. If "Common Rail Pressure" does not follow "Target Common Rail Pressure", proceed to step 17.

- If "Common Rail Pressure" does not follow "Target Common Rail Pressure", the fuel filter may be clogged.

"Target Common Rail Pressure" means target fuel pressure controlled by the ECM.

"Common Rail Pressure" means actual fuel pressure in common rail assembly.

If the pressure discharge valve mounted on the common rail assembly is malfunctioning, the actual fuel pressure may change as indicated by "Pressure Discharge Valve Malfunctioning" in the illustration.

The pressure discharge valve operates to discharge fuel pressure when the internal pressure of the common rail exceeds the target fuel pressure.

| 17.INSPECT COMMON RAIL ASSEMBLY (FOR BANK 2) (PRESSURE DISCHARGE VALVE) |

Enter the following menus: Engine and ECT / Utility / Pressure Discharge Valve Check ().

Select "Always Closed Check".

Read the Value of fuel pressure values.

- OK:

- Common rail pressure is properly maintained.

If the fuel pressure cannot be maintained, the pressure discharge valve may not have a tight seal.

If the common rail pressure is being properly maintained, there are no problems with the sealing properties of the high-pressure fuel system. Therefore, an insufficient supply of fuel due to the fuel filter being clogged, or squashed or blocked low-pressure fuel pipes or hoses may be causing the reduction in common rail pressure.

| 18.INSPECT CLOGGED FUEL PIPE |

Connect the GTS to the DLC3.

Start the engine and turn the GTS on.

Enter the following menus: Engine and ECT / Data List / Diesel Injection.

With no load after the engine is warmed up, take a snapshot when idling and when the vehicle is accelerating with the accelerator pedal fully depressed in 2nd gear.

Check the Target Common Rail Pressure and Fuel Press value.

Result| Result | Proceed to |

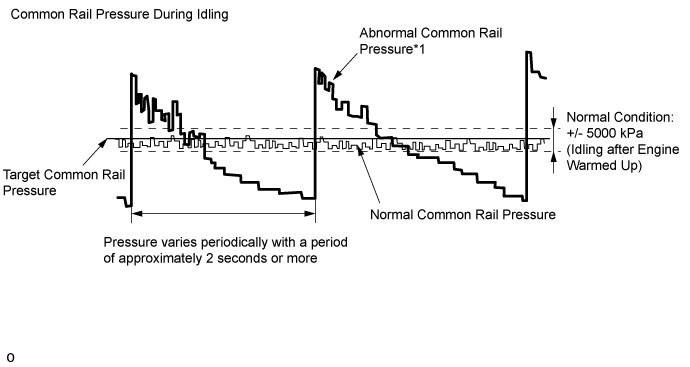

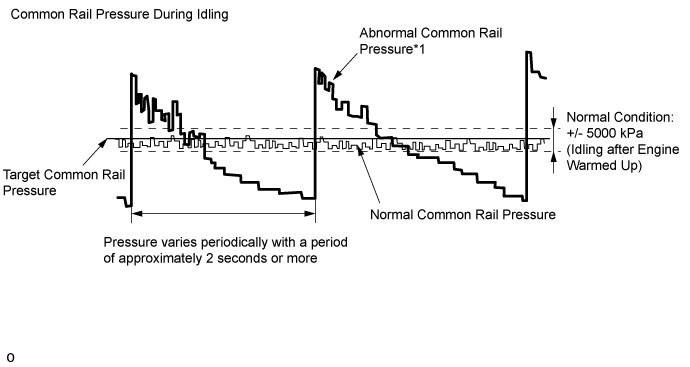

| While idling the vehicle, "Common Rail Pressure" deviates from the normal range and varies periodically with a period of approximately 2 seconds or more*1 | A |

| "Common Rail Pressure" is normal while idling the vehicle, but "Fuel Press" does not follow "Target Common Rail Pressure" when the accelerator pedal is fully depressed in 2nd gear*2 |

| Except above | B |

*1: The cause may be a squashed or blocked fuel pipe or hose.

*2: The cause may be a clogged fuel filter.

| 19.REPAIR OR REPLACE CLOGGED FUEL LINE |

Repair or replace the clogged (including frozen fuel) fuel pipe.

Replace the fuel filter element sub-assembly.

- If "Common Rail Pressure" does not follow "Target Common Rail Pressure" when the accelerator pedal is fully depressed in 2nd gear, replace the fuel filter element sub-assembly.

| 20.REPLACE COMMON RAIL ASSEMBLY (FOR BANK 2) (PRESSURE DISCHARGE VALVE) |

Replace the common rail assembly (for bank 2) ().

| 21.BLEED AIR FROM FUEL SYSTEM |

Bleed the air from the fuel system ().

Perform PM forced regeneration ().

- When fuel lines are disconnected, air may enter the fuel lines, leading to engine starting trouble. Therefore, perform forced regeneration and bleed the air from the fuel lines.

| 22.READ VALUE USING GTS (COMMON RAIL PRESSURE AND TARGET COMMON RAIL PRESSURE) |

Check Common Rail Pressure and Target Common Rail Pressure in the snapshot taken in procedure 3 when the engine was idling.

Result| Result | Proceed to |

| Difference between Common Rail Pressure and Target Common Rail Pressure is 5000 kPa (51.0 kgf/cm2, 725 psi) or more | B |

| Except above | A |

| 23.REPLACE FUEL SUPPLY PUMP ASSEMBLY (SUCTION CONTROL VALVE) |

Replace the fuel supply pump assembly ().

| 24.BLEED AIR FROM FUEL SYSTEM |

Bleed the air from the fuel system ().

Perform PM forced regeneration ().

- When fuel lines are disconnected, air may enter the fuel lines, leading to engine starting trouble. Therefore, perform forced regeneration and bleed the air from the fuel lines.

| 25.PERFORM SUPPLY PUMP INITIALIZATION |

Perform supply pump initialization ().

| 26.CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |