DESCRIPTION

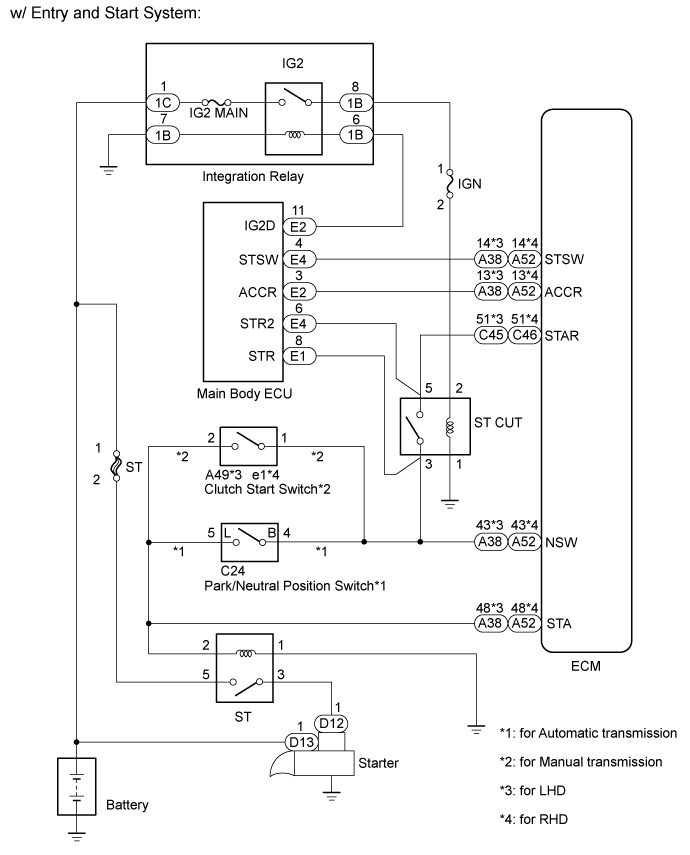

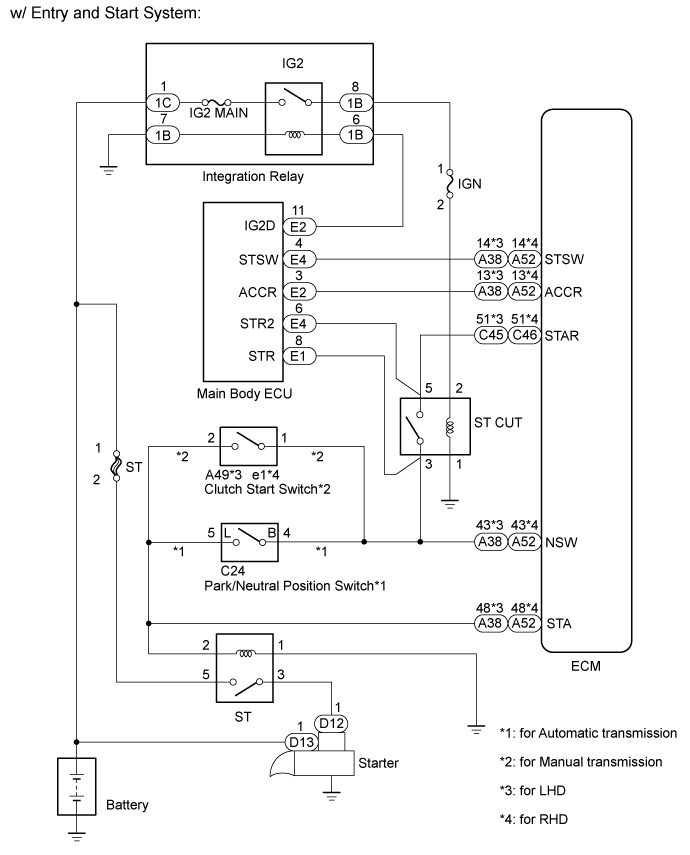

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK IF VEHICLE IS EQUIPPED WITH ENTRY AND START SYSTEM

READ VALUE USING INTELLIGENT TESTER (STARTER SIGNAL)

INSPECT PARK/NEUTRAL POSITION SWITCH ASSEMBLY

REPLACE PARK/NEUTRAL POSITION SWITCH ASSEMBLY

INSPECT CLUTCH START SWITCH

REPLACE CLUTCH START SWITCH

READ VALUE USING INTELLIGENT TESTER (STARTER SIGNAL)

CHECK HARNESS AND CONNECTOR (PNP SWITCH OR CLUTCH START SWITCH - STA TERMINAL OF ECM)

CHECK WHETHER DTC OUTPUT RECURS

READ VALUE USING INTELLIGENT TESTER (STARTER SIGNAL)

INSPECT PARK/NEUTRAL POSITION SWITCH ASSEMBLY

REPLACE PARK/NEUTRAL POSITION SWITCH ASSEMBLY

INSPECT CLUTCH START SWITCH ASSEMBLY

REPLACE CLUTCH START SWITCH ASSEMBLY

INSPECT IGNITION OR STARTER SWITCH ASSEMBLY

REPLACE IGNITION OR STARTER SWITCH ASSEMBLY

READ VALUE USING INTELLIGENT TESTER (STARTER SIGNAL)

CHECK HARNESS AND CONNECTOR (PNP SWITCH OR CLUTCH START SWITCH - STA TERMINAL OF ECM)

CHECK WHETHER DTC OUTPUT RECURS

DTC P0617 Starter Relay Circuit High

DESCRIPTION

While the engine is being cranked, positive battery voltage is applied to terminal STA of the ECM.

If the ECM detects the starter control (STA) signal while the vehicle is being driven, it determines that there is a malfunction in the STA circuit. The ECM then illuminates the MIL and stores the DTC.

This monitor runs when the vehicle has been driven at 20 km/h (12.4 mph) or more for more than 20 seconds.

P0617| DTC Detection Drive Pattern | DTC Detection Condition | Trouble Area |

| Drive vehicle for 25 seconds or more at a speed of 20 km/h (12.4 mph) or more and an engine speed of 1000 rpm or more | Conditions (a), (b) and (c) are met for 20 seconds

(a) Vehicle speed is more than 20 km/h (12.4 mph).

(b) Engine speed is more than 1000 rpm.

(c) STA signal is on. | Park/neutral position switch (A/T)

Starter relay circuit

Clutch start switch (M/T)

|

Related Data List| DTC No. | Data List |

| P0617 | Starter Signal |

WIRING DIAGRAM

INSPECTION PROCEDURE

- After replacing the ECM, the new ECM needs registration () and initialization ().

The following troubleshooting process is based on the premise that the engine can crank normally. If the engine does not crank, proceed to the Problem Symptoms Table ().

Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, and other data from the time the malfunction occurred.

| 1.CHECK IF VEHICLE IS EQUIPPED WITH ENTRY AND START SYSTEM |

Check if the vehicle is equipped with the entry and start system.

Result| Result | Proceed to |

| w/ Entry and Start System | A |

| w/o Entry and Start System | B |

| 2.READ VALUE USING INTELLIGENT TESTER (STARTER SIGNAL) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON and turn the tester on.

Enter the following menus: Powertrain / Engine / Data List / All Data / Starter Signal.

Check the value displayed on the tester when the ignition switch is turned to ON and the engine is started.

- OK:

| Ignition Switch Condition | Starter Signal |

| ON | OFF |

| Engine started | ON |

Result| Result | Proceed to |

| NG (A/T) | A |

| NG (M/T) | B |

| OK | C |

| |

|

| | CHECK FOR INTERMITTENT PROBLEMS ()

|

|

|

| 3.INSPECT PARK/NEUTRAL POSITION SWITCH ASSEMBLY |

Inspect the park/neutral position switch ().

Result| Result | Proceed to |

| NG | A |

| OK | B |

| 4.REPLACE PARK/NEUTRAL POSITION SWITCH ASSEMBLY |

Replace the park/neutral position switch ().

| 5.INSPECT CLUTCH START SWITCH |

Check the clutch start switch (for LHD) ().

Check the clutch start switch (for RHD) ().

Result| Result | Proceed to |

| NG | A |

| OK | B |

| 6.REPLACE CLUTCH START SWITCH |

Replace the clutch start switch (for LHD) ().

Replace the clutch start switch (for RHD) ().

| 7.READ VALUE USING INTELLIGENT TESTER (STARTER SIGNAL) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON and turn the tester on.

Enter the following menus: Powertrain / Engine / Data List / All Data / Starter Signal.

Check the value displayed on the tester when the ignition switch is turned to ON and the engine is started.

- OK:

| Ignition Switch Condition | Starter Signal |

| ON | OFF |

| Engine started | ON |

Result| Result | Proceed to |

| NG | A |

| OK | B |

| 8.CHECK HARNESS AND CONNECTOR (PNP SWITCH OR CLUTCH START SWITCH - STA TERMINAL OF ECM) |

| | REPLACE HARNESS OR CONNECTOR |

|

|

| 9.CHECK WHETHER DTC OUTPUT RECURS |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON.

Drive the vehicle at 20 km/h (12.4 mph) or more for 20 seconds or more.

Enter the following menus: Powertrain / Engine / DTC.

Read the DTCs.

Result| Display (DTC Output) | Proceed to |

| P0617 | A |

| No output | B |

| A | |

| |

| GO TO CRANKING HOLDING FUNCTION CIRCUIT ()

|

|

| 10.READ VALUE USING INTELLIGENT TESTER (STARTER SIGNAL) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON and turn the tester on.

Enter the following menus: Powertrain / Engine / Data List / All Data / Starter Signal.

Check the value displayed on the tester when the ignition switch is turned to ON and the engine is started.

- OK:

| Ignition Switch Condition | Starter Signal |

| ON | OFF |

| Engine started | ON |

Result| Result | Proceed to |

| NG (A/T) | A |

| NG (M/T) | B |

| OK | C |

| |

|

| | CHECK FOR INTERMITTENT PROBLEMS ()

|

|

|

| 11.INSPECT PARK/NEUTRAL POSITION SWITCH ASSEMBLY |

Inspect the park/neutral position switch ().

Result| Result | Proceed to |

| NG | A |

| OK | B |

| 12.REPLACE PARK/NEUTRAL POSITION SWITCH ASSEMBLY |

Replace the park/neutral position switch ().

| 13.INSPECT CLUTCH START SWITCH ASSEMBLY |

Check the clutch start switch (for LHD) ().

Check the clutch start switch (for RHD) ().

Result| Result | Proceed to |

| NG | A |

| OK | B |

| 14.REPLACE CLUTCH START SWITCH ASSEMBLY |

Replace the clutch start switch (for LHD) ().

Replace the clutch start switch (for RHD) ().

| 15.INSPECT IGNITION OR STARTER SWITCH ASSEMBLY |

Inspect the Ignition or Starter Switch Assembly ().

Result| Result | Proceed to |

| NG | A |

| OK | B |

| 16.REPLACE IGNITION OR STARTER SWITCH ASSEMBLY |

Replace the Ignition or Starter Switch Assembly ().

| 17.READ VALUE USING INTELLIGENT TESTER (STARTER SIGNAL) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON and turn the tester on.

Enter the following menus: Powertrain / Engine / Data List / All Data / Starter Signal.

Check the value displayed on the tester when the ignition switch is turned to ON and the engine is started.

- OK:

| Ignition Switch Condition | Starter Signal |

| ON | OFF |

| Engine started | ON |

Result| Result | Proceed to |

| NG | A |

| OK | B |

| 18.CHECK HARNESS AND CONNECTOR (PNP SWITCH OR CLUTCH START SWITCH - STA TERMINAL OF ECM) |

| | REPLACE HARNESS OR CONNECTOR |

|

|

| 19.CHECK WHETHER DTC OUTPUT RECURS |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON.

Drive the vehicle at 20 km/h (12.4 mph) or more for 20 seconds or more.

Enter the following menus: Powertrain / Engine / DTC.

Read the DTCs.

Result| Display (DTC Output) | Proceed to |

| P0617 | A |

| No output | B |