Land Cruiser URJ200 URJ202 GRJ200 VDJ200 - 1VD-FTV ENGINE CONTROL

READ VALUE USING GTS (STARTER SIGNAL)

INSPECT PARK/NEUTRAL POSITION SWITCH ASSEMBLY

CHECK HARNESS AND CONNECTOR (PARK/NEUTRAL POSITION SWITCH - ECM)

REPLACE PARK/NEUTRAL POSITION SWITCH ASSEMBLY

REPAIR OR REPLACE HARNESS OR CONNECTOR

CONFIRM WHETHER DTC OUTPUT RECURS

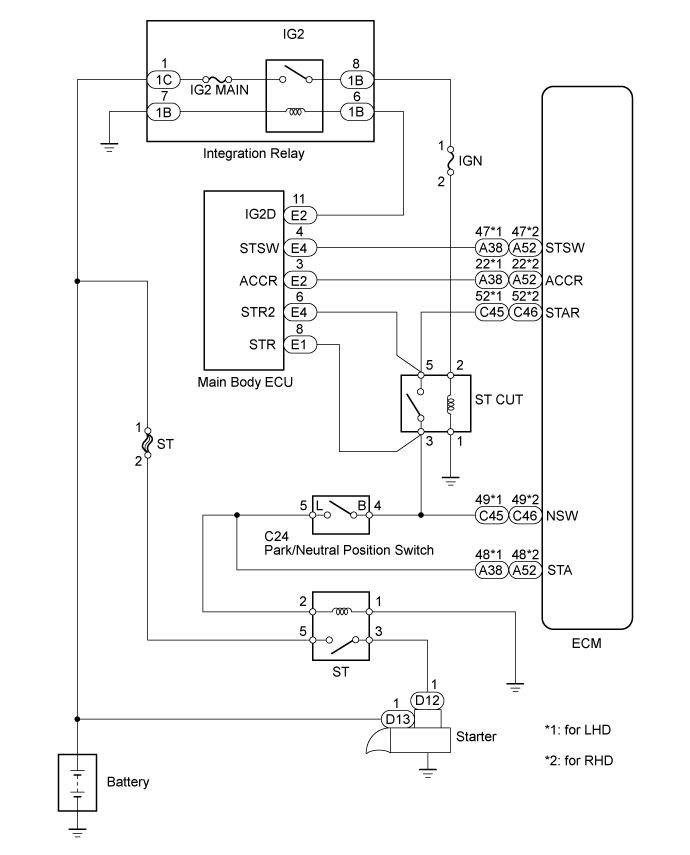

DTC P0617 Starter Relay Circuit High

DESCRIPTION

While the engine is being cranked, positive battery voltage is applied to terminal STA of the ECM.

If the ECM detects the starter control (STA) signal while the vehicle is being driven, it determines that there is a malfunction in the STA circuit. The ECM then illuminates the MIL and stores the DTC.

This monitor runs when the vehicle has been driven at 20 km/h (12.5 mph) or more for more than 20 seconds.

| DTC Detection Drive Pattern | DTC Detection Condition | Trouble Area |

| Drive the vehicle for 25 seconds or more at a speed of 20 km/h (12.5 mph) or more and an engine speed of 1000 rpm or more | Conditions (a), (b) and (c) are met for 20 seconds (1 trip detection logic): (a) Vehicle speed is more than 20 km/h (12.5 mph). (b) Engine speed is more than 1000 rpm. (c) STA signal is on. | Starter relay (ST) circuit Park/neutral position switch assembly ECM |

| DTC No. | Data List |

| P0617 | Starter Signal |

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- HINT:

| 1.READ VALUE USING GTS (STARTER SIGNAL) |

Connect the GTS to the DLC3.

Turn the engine switch on (IG) and turn the GTS on.

Enter the following menus: Engine and ECT / Data List / Starter Signal.

Read the value displayed on the GTS when the engine switch is turned on (IG) and when the engine is started.

- OK:

Condition Starter Signal Engine switch turned on (IG) Close Engine started Open

|

| ||||

| NG | |

| 2.INSPECT PARK/NEUTRAL POSITION SWITCH ASSEMBLY |

Inspect the park/neutral position switch assembly ().

|

| ||||

| OK | |

| 3.CHECK HARNESS AND CONNECTOR (PARK/NEUTRAL POSITION SWITCH - ECM) |

Disconnect the park/neutral position switch assembly connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

for LHD Tester Connection Condition Specified Condition C45-49 (NSW) - A38-48 (STA) Always 10 kΩ or higher C45-49 (NSW) or A38-48 (STA) - Body ground and other terminals Always 10 kΩ or higher

- Standard Resistance:

for RHD Tester Connection Condition Specified Condition C46-49 (NSW) - A52-48 (STA) Always 10 kΩ or higher C46-49 (NSW) or A52-48 (STA) - Body ground and other terminals Always 10 kΩ or higher

Reconnect the park/neutral position switch assembly connector.

Reconnect the ECM connector.

|

| ||||

| OK | |

| 4.REPLACE ECM |

Replace the ECM ().

|

| ||||

| 5.REPLACE PARK/NEUTRAL POSITION SWITCH ASSEMBLY |

Replace the park/neutral position switch assembly ().

|

| ||||

| 6.REPAIR OR REPLACE HARNESS OR CONNECTOR |

Repair or replace the harness or connector.

| NEXT | |

| 7.CONFIRM WHETHER DTC OUTPUT RECURS |

Connect the GTS to the DLC3.

Clear the DTCs ().

Turn the engine switch off.

Turn the engine switch on (IG).

Drive the vehicle for 25 seconds or more at a speed of 20 km/h (12.5 mph) or more and an engine speed of 1000 rpm or more.

Confirm that the DTC is not output again.

| NEXT | ||

| ||