Land Cruiser URJ200 URJ202 GRJ200 VDJ200 - 1GR-FE ENGINE CONTROL

CHECK FOR ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0017 OR P0019)

PERFORM ACTIVE TEST USING GTS (OPERATE CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY FOR EXHAUST SIDE)

CHECK WHETHER DTC OUTPUT RECURS (DTC P0017 OR P0019)

CHECK VALVE TIMING (CHECK FOR LOOSE TEETH AND WHETHER TIMING CHAIN HAS JUMPED TOOTH)

INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (FOR EXHAUST SIDE)

CHECK OIL CONTROL VALVE FILTER AND OIL PIPE

REPLACE CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY

CHECK WHETHER DTC OUTPUT RECURS (DTC P0017 OR P0019)

DTC P0017 Crankshaft Position - Camshaft Position Correlation (Bank 1 Sensor B)

DTC P0019 Crankshaft Position - Camshaft Position Correlation (Bank 2 Sensor B)

DESCRIPTION

In the VVT (Variable Valve Timing) system, the appropriate exhaust valve open and close timing is controlled by the ECM. The ECM performs exhaust valve control by performing the following: 1) controlling the camshaft and camshaft timing oil control valve, and operating the camshaft timing gear; and 2) changing the relative positions of the camshaft and crankshaft.

| DTC No. | DTC Detection Condition | Trouble Area |

| P0017 | Deviations in the crankshaft position sensor and VVT sensor 1 (for exhaust camshaft) signals (2 trip detection logic). | Valve timing Camshaft timing oil control valve assembly (for exhaust side) Oil control valve filter Camshaft timing exhaust gear assembly ECM |

| P0019 | Deviations in the crankshaft position sensor and VVT sensor 2 (for exhaust camshaft) signals (2 trip detection logic). |

MONITOR DESCRIPTION

To monitor the correlation of the exhaust camshaft position and crankshaft position, the ECM checks the VVT learned value while the engine is idling. The VVT learned value is calibrated based on the camshaft position and crankshaft position. The exhaust valve timing is set to the most advanced angle while the engine is idling. If the VVT learned value is out of the specified range in consecutive driving cycles, the ECM illuminates the MIL and stores DTC P0017 (Bank 1) or P0019 (Bank 2).

WIRING DIAGRAM

Refer to DTC P0335 ().

Refer to DTC P0365 ().

INSPECTION PROCEDURE

- HINT:

*: The No. 1 cylinder is the cylinder which is farthest from the transmission.

| 1.CHECK FOR ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0017 OR P0019) |

Connect the GTS to the DLC3.

Turn the ignition switch to ON and turn the GTS on.

Enter the following menus: Powertrain / Engine and ECT / Trouble Codes.

Read the DTCs.

| Result | Proceed to |

| P0017 or P0019 is output | A |

| P0017 or P0019 and other DTCs are output | B |

- HINT:

- If any DTCs other than P0017 or P0019 are output, troubleshoot those DTCs first.

|

| ||||

| A | |

| 2.PERFORM ACTIVE TEST USING GTS (OPERATE CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY FOR EXHAUST SIDE) |

Connect the GTS to the DLC3.

Start the engine and turn the GTS on.

Warm up the engine.

Turn the A/C on.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the VVT Exhaust Linear (Bank 1) or Control the VVT Exhaust Linear (Bank 2).

Perform the Active Test. Check that the displacement angle varies.

- OK:

- Displacement angle varies.

|

| ||||

| OK | |

| 3.CHECK WHETHER DTC OUTPUT RECURS (DTC P0017 OR P0019) |

Connect the GTS to the DLC3.

Turn the ignition switch to ON and turn the GTS on.

Clear the DTCs ().

Start the engine and warm it up.

Switch the ECM from normal mode to check mode using the GTS ().

Drive the vehicle for more than 10 minutes.

Read the DTCs using the GTS.

- OK:

- No DTC output.

|

| ||||

| OK | ||

| ||

| 4.CHECK VALVE TIMING (CHECK FOR LOOSE TEETH AND WHETHER TIMING CHAIN HAS JUMPED TOOTH) |

Remove the cylinder head cover RH and LH.

| *1 | Timing Mark |

Turn the crankshaft pulley and align its groove with the "0" timing mark on the timing chain cover.

Check that the timing marks on the camshaft timing gears are aligned with the timing marks of the bearing cap as shown in the illustration.

- OK:

- Timing marks on camshaft timing gears are aligned as shown in the illustration.

|

| ||||

| OK | |

| 5.INSPECT CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY (FOR EXHAUST SIDE) |

Inspect the camshaft timing oil control valve assembly ().

|

| ||||

| OK | |

| 6.CHECK OIL CONTROL VALVE FILTER AND OIL PIPE |

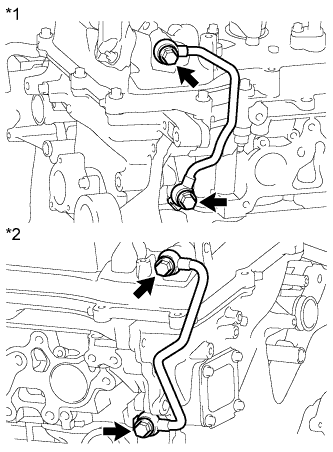

Remove the No. 1 or No. 2 oil pipe.

| *1 | No. 1 Oil Pipe |

| *2 | No. 2 Oil Pipe |

Remove the oil control valve filter.

Check that the filter and pipe are not clogged.

- OK:

- The filter and pipe are not clogged.

|

| ||||

| OK | |

| 7.REPLACE CAMSHAFT TIMING EXHAUST GEAR ASSEMBLY |

Replace the camshaft timing exhaust gear assembly ().

| NEXT | |

| 8.CHECK WHETHER DTC OUTPUT RECURS (DTC P0017 OR P0019) |

Connect the GTS to the DLC3.

Turn the ignition switch to ON and turn the GTS on.

Clear the DTCs ().

Start the engine and warm it up.

Switch the ECM from normal mode to check mode using the GTS ().

Drive the vehicle for more than 10 minutes.

Confirm that no DTC is output using the GTS.

- OK:

- No DTC output.

- HINT:

- DTC P0017 or P0019 is stored when foreign objects in the engine oil are caught in some parts of the system. These codes will remain stored even if the system returns to normal after a short time. These foreign objects are then captured by the oil filter, thus eliminating the source of the problem.

|

| ||||

| OK | ||

| ||