1. INSTALL FLYWHEEL RING GEAR (for Manual Transmission)

-

Using a torch, heat the ring gear evenly to approximately 200°C (392°F).

NOTICE:

Be careful not to overheat the ring gear.

-

Using a brass bar, tap the ring gear onto the flywheel with its chamfered gear teeth facing the block.

NOTICE:

After installing, allow the ring gear to cool before handling.

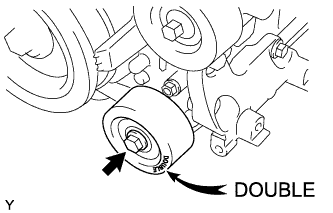

2. INSTALL NO. 1 IDLER PULLEY SUB-ASSEMBLY

-

Install the No. 1 idler pulley with the bolt.

Torque:

54 N*m{ 551 kgf*cm , 40 ft.*lbf }

HINT:

"DOUBLE" is marked on the No. 1 idler pulley to distinguish it from the No. 2 idler pulley.

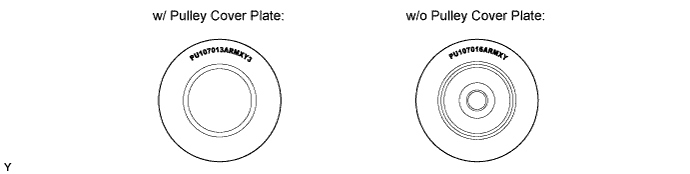

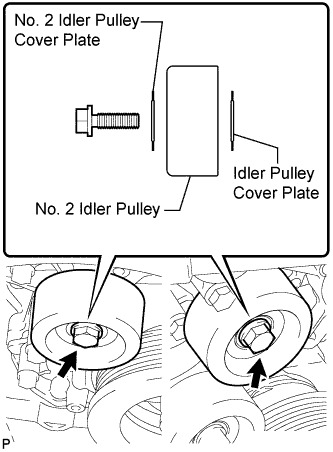

3. INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY

-

w/ Pulley Cover Plate:

-

Install the idler pulley cover plate, idler pulley and No. 2 idler pulley cover plate with the bolt.

Torque:

54 N*m{ 551 kgf*cm , 40 ft.*lbf }

NOTICE:

If it is necessary to replace the pulley or either plate, replace the No. 2 idler pulley cover plate, No. 2 idler pulley and idler pulley cover plate as a set with new parts.

-

-

w/o Pulley Cover Plate: Install the 2 No. 2 idler pulleys with the 2 bolts.

Torque:

54 N*m{ 551 kgf*cm , 40 ft.*lbf }

4. INSTALL FRONT NO. 1 ENGINE MOUNTING BRACKET LH

-

Install the engine mounting bracket with the 3 bolts.

Torque:

43 N*m{ 438 kgf*cm , 32 ft.*lbf }

5. INSTALL FRONT NO. 1 ENGINE MOUNTING BRACKET RH

-

Install the engine mounting RH with the 4 bolts.

Torque:

43 N*m{ 438 kgf*cm , 32 ft.*lbf }

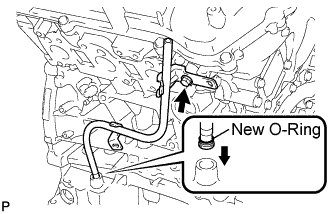

6. INSTALL ENGINE OIL LEVEL DIPSTICK GUIDE

-

Install a new O-ring to the dipstick guide.

-

Apply a light coat of engine oil to the O-ring.

-

Push the dipstick guide end into the guide hole.

-

Install the dipstick guide with the bolt.

Torque:

9.0 N*m{ 92 kgf*cm , 80 in.*lbf }

7. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

-

Temporarily install the V-ribbed belt tensioner with the 5 bolts.

-

Tighten bolt 1 and 2 in numerical order.

Torque:

36 N*m{ 367 kgf*cm , 27 ft.*lbf }

-

Tighten the other bolts.

Torque:

36 N*m{ 367 kgf*cm , 27 ft.*lbf }

Standard Bolt:

Item Length A 70 mm (2.76 in.) B 33 mm (1.30 in.)

8. INSTALL IGNITION COIL ASSEMBLY

-

Install the 6 ignition coils with the 6 bolts.

Torque:

10 N*m{ 102 kgf*cm , 7 ft.*lbf }

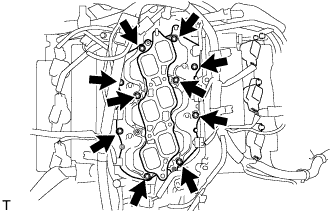

9. INSTALL ENGINE WIRE

10. INSTALL INTAKE MANIFOLD

-

Set a new gasket on each cylinder head.

NOTICE:

- Align the port holes of the gasket and cylinder head.

- Be careful of the installation direction.

-

Set the intake manifold on the cylinder heads.

-

Install and uniformly tighten the 10 bolts in several passes.

Torque:

26 N*m{ 265 kgf*cm , 19 ft.*lbf }

HINT:

Tighten the inner installation bolts of the intake manifold before tightening the outer bolts.

11. INSTALL FUEL INJECTOR

-

Install a new insulator onto each fuel injector.

-

Apply a light coat of spindle oil or gasoline to each new O-ring and install one onto each fuel injector.

-

Install the 6 injectors.

-

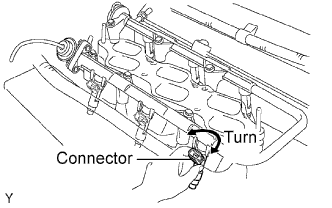

While turning each fuel injector left and right, install it onto the fuel delivery pipe.

-

Position the fuel injector connectors facing outward.

-

12. INSTALL FUEL DELIVERY PIPE SUB-ASSEMBLY

-

Place the fuel delivery pipe together with the 6 fuel injectors on the intake manifold.

-

Temporarily install the 6 bolts, which are used to hold the fuel delivery pipe, to the intake manifold.

-

Check that the fuel injectors rotate smoothly.

HINT:

If the fuel injectors do not rotate smoothly, replace the O-ring of any injector that does not rotate smoothly.

-

Position the fuel injector connectors facing outward.

-

Tighten the 6 bolts, which are used to hold the fuel delivery pipe, to the intake manifold.

Torque:

15 N*m{ 153 kgf*cm , 11 ft.*lbf }

-

Connect the 6 fuel injector connectors.

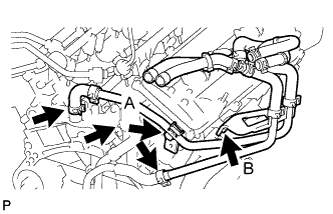

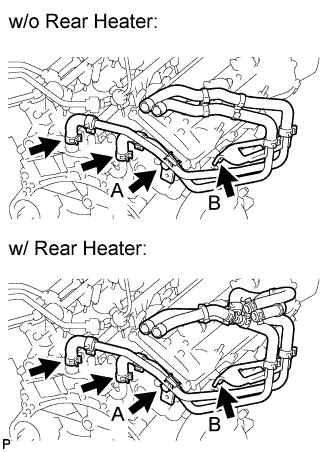

13. CONNECT WATER HOSE SUB-ASSEMBLY (for Automatic Transmission)

-

Connect the heater water by-pass pipe hose to the rear water by-pass joint.

-

Temporarily install the heater water pipe, and then tighten the 2 bolts in the order shown in the illustration.

Torque:

for bolt A:

9.8 N*m{ 100 kgf*cm , 87 in.*lbf }

for bolt B:

13 N*m{ 138 kgf*cm , 10 ft.*lbf }

14. CONNECT WATER HOSE SUB-ASSEMBLY (for Manual Transmission)

-

Connect the heater water by-pass pipe hose to the rear water by-pass joint.

-

Temporarily install the heater water pipe, and then tighten the 2 bolts in the order shown in the illustration.

Torque:

for bolt A:

9.8 N*m{ 100 kgf*cm , 87 in.*lbf }

for bolt B:

13 N*m{ 138 kgf*cm , 10 ft.*lbf }

15. CONNECT NO. 1 WATER BY-PASS PIPE (for Automatic Transmission)

-

Connect the water by-pass pipe hoses to the water by-pass pipe and No. 1 water outlet pipe.

16. INSTALL ENGINE COOLANT TEMPERATURE SENSOR

-

Install a new gasket and the engine coolant temperature sensor.

Torque:

20 N*m{ 204 kgf*cm , 15 ft.*lbf }

17. INSTALL OIL PRESSURE SENSOR

-

Apply adhesive to 2 or 3 threads of the oil pressure sensor.

Adhesive:

Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

-

Using a 24 mm deep socket wrench, install the oil pressure sensor.

Torque:

15 N*m{ 150 kgf*cm , 11 ft.*lbf }

NOTICE:

Do not start the engine within 1 hour of installation.