1. INSPECT CONNECTING ROD THRUST CLEARANCE

-

Using a dial indicator, measure the thrust clearance while moving the connecting rod back and forth.

Standard thrust clearance:

0.15 to 0.30 mm (0.00591 to 0.0118 in.)

Maximum thrust clearance:

0.35 mm (0.0138 in.)

If the thrust clearance is more than the maximum, replace one or more connecting rods as necessary. If necessary, replace the crankshaft.

2. REMOVE PISTON SUB-ASSEMBLY WITH CONNECTING ROD

-

Using a ridge reamer, remove all the carbon from the top of the cylinder.

-

Uniformly loosen the connecting rod bolts, and remove the connecting rod cap with bearing.

-

Push out the piston with connecting rod and upper bearing through the top of the cylinder block.

HINT:

- Keep the bearings, connecting rod and cap together.

- Arrange the piston and connecting rod assemblies in the correct order.

3. REMOVE CONNECTING ROD BEARING

4. REMOVE PISTON RING SET

-

Using a piston ring expander, remove the 2 compression rings.

-

Remove the 2 side rails and oil ring (expander) by hand.

5. REMOVE PISTON PIN HOLE SNAP RING

-

Using a screwdriver, pry out the 2 snap rings.

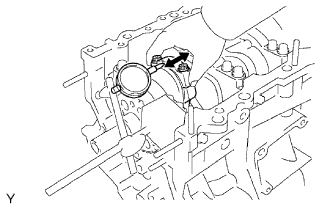

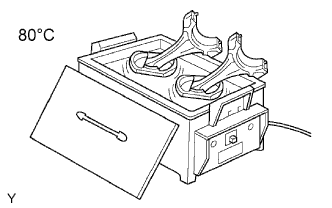

6. REMOVE PISTON WITH PIN SUB-ASSEMBLY

-

Gradually heat the piston to approximately 80°C (176°F).

-

Using a plastic-faced hammer and brass bar, lightly tap out the piston pin and remove the connecting rod.

HINT:

- The piston and pin are a matched set.

- Arrange the pistons, pins, rings, connecting rods and bearings in the correct order.

7. INSPECT CRANKSHAFT THRUST CLEARANCE

-

Using a dial indicator, measure the thrust clearance while prying the crankshaft back and forth with a screwdriver.

Standard thrust clearance:

0.04 to 0.24 mm (0.00157 to 0.00945 in.)

Maximum thrust clearance:

0.30 mm (0.0118 in.)

If the thrust clearance is more than the maximum, replace the thrust washers as a set.

Standard thrust washer thickness:

1.93 to 1.98 mm (0.0760 to 0.0780 in.)

If necessary, replace the crankshaft.

8. REMOVE CRANKSHAFT

-

Using several steps, loosen and remove the 8 bearing cap bolts and seal washers uniformly in the sequence shown in the illustration.

-

Using several steps, loosen and remove the 16 bearing cap bolts uniformly in the sequence shown in the illustration.

-

Using a screwdriver, pry out the bearing caps. Remove the 4 bearing caps and lower bearings.

NOTICE:

- Push up on the cap little by little, alternating from the right and left side until the cap can be removed.

- Be careful not to damage the joint surfaces of the cylinder block and bearing cap.

9. REMOVE CRANKSHAFT BEARING

10. REMOVE NO. 1 OIL NOZZLE SUB-ASSEMBLY

-

Using a 5 mm hexagon socket wrench, remove the 3 bolts and 3 oil nozzles.