Fuel Injector -- Installation |

| 1. INSTALL INJECTOR |

- NOTICE:

- Be sure to install the injector, holder clamp, washer and bolt in their original positions.

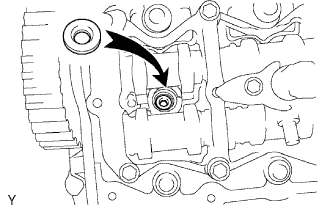

Install 4 new injection nozzle sheets to the cylinder head.

|

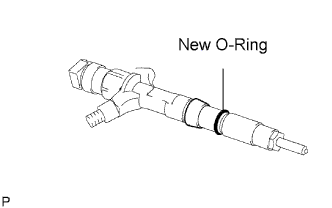

Apply a light amount of clean engine oil to 4 new O-rings.

Install an O-ring to each injector as shown in the illustration.

|

Insert the 4 injectors into the cylinder head.

- NOTICE:

- Insert the injector until it touches the nozzle sheet surface.

- After installing the injector to the cylinder head, the O-ring may prevent the injector from fully seating. If so, pull out the injector and reinstall it.

- Always reinstall an injector to the same place it was removed from.

For an injector that has been replaced with a new injector, register the injector compensation code (Toyota Fortuner RM0000012XK005X.html).

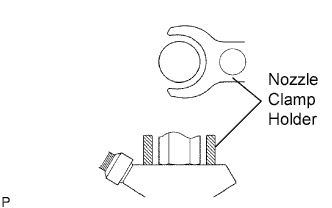

Temporarily install 4 new washers and the 4 nozzle clamps with the 4 clamp bolts.

- HINT:

- Apply a light amount of engine oil to the threads and under the heads of the clamp bolts.

- NOTICE:

- The fork portion of the nozzle holder clamp must be set to the injector.

- Before tightening the bolts, check that the nozzle holder clamp is set properly.

- To fasten the clamp bolts, first tighten them by hand until they cannot be turned further. Then, tighten the bolts to the specified torque in the following step.

- When tightening the bolts, be careful not to tilt the bolt and clamp.

- Do not reuse the washer.

- If the nozzle leakage pipe is accidentally tightened beyond the torque specification, it must be replaced.

|

Temporarily install the 4 injection pipes with the union nuts.

- HINT:

- To position the injectors, loosely tighten the union nut.

Check the nozzle leakage pipe. Check that there are no scratches or dents on the 5 union seal surfaces.

If scratches or dents are present, replace the nozzle leakage pipe.

|

Set the leakage pipe and 5 new gaskets in place.

|

Apply a light amount of oil to the 4 hollow screws and union bolt.

Temporarily install the leakage pipe with the 4 hollow screws and union bolt.

|

Tighten the 4 holder clamp bolts.

- Torque:

- 22 N*m{224 kgf*cm, 16 ft.*lbf}

Tighten the 4 hollow screws in order from 1 to 4.

- Torque:

- 16 N*m{163 kgf*cm, 12 ft.*lbf}

- NOTICE:

- If a hollow screw is accidentally tightened beyond the torque specification, it must be replaced.

|

Tighten the union bolt.

- Torque:

- 12.5 N*m{127 kgf*cm, 9 ft.*lbf}

- NOTICE:

- If the union bolt is accidentally tightened beyond the torque specification, it must be replaced.

Remove the 4 injection pipes.

| 2. CHECK FOR FUEL LEAKS |

|

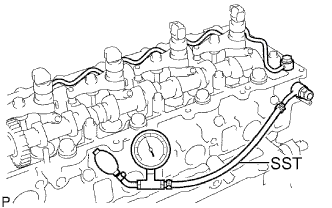

Check that there are no leaks from the nozzle leakage pipe connection.

Install the gasket and No. 2 nozzle leakage pipe to the cylinder head with SST (check valve).

- Part No.:

- 23762-27010 (No. 2 nozzle leakage pipe)

- SST

- 09280-00010

- Torque:

- 21 N*m{214 kgf*cm, 16 ft.*lbf}

Apply a light amount of soapy water (or other fluid for detecting fuel leakage) on the nozzle leakage pipe connection.

Install SST (turbocharger pressure gauge) to the fuel return side of the leakage pipe, and maintain 100 kPa (1.0 kgf/cm2, 14.5 psi) of pressure for 60 seconds to check that no bubbles form.

- SST

- 09992-00242

- NOTICE:

- Before checking the leakage, be sure to remove the ball and spring in the check valve.

After checking for fuel leaks, wipe off the soapy water from the leakage pipe connection.

Remove SST, No. 2 nozzle leakage pipe and gasket.

- SST

- 09280-00010

09992-00242

- HINT:

- Never reinstall the disassembled check valve on the engine.

| 3. INSTALL CYLINDER HEAD COVER |

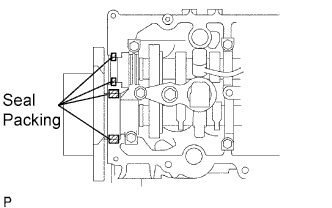

Remove any old seal packing (FIPG) material from the cylinder head.

Apply seal packing to the specific areas shown in the illustration.

- Seal packing:

- Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

- NOTICE:

- Remove any oil from the contact surface.

- Install the belt cover within 3 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after installing the seal packing.

|

Install the gasket and cylinder head cover with the 10 bolts and 2 nuts.

- Torque:

- 9.0 N*m{92 kgf*cm, 80 in.*lbf}

|

Connect the ventilation hose.

|

Connect the 4 connectors.

Install 4 new nozzle holder seals.

| 4. INSTALL INJECTION PIPE |

|

- NOTICE:

- When replacing the injector, also replace the injection pipe.

- Keep the joints of the injection pipe clean.

Temporarily install the No. 1, No. 2 and No. 3 injection pipes with the union nuts.

Install the No. 2 and No. 3 injection pipe clamps with the bolt and 2 nuts, as shown in the illustration.

- Torque:

- 5.0 N*m{51 kgf*cm, 44 in.*lbf}

- HINT:

- If the painted mark on the No. 1 injection pipe has disappeared, use the illustration as a reference to install the clamps.

Using union nut wrench, tighten the injection pipe union nuts on the common rail side.

- Torque:

- 32 N*m{326 kgf*cm, 24 ft.*lbf} for use with union nut wrench

- 35 N*m{357 kgf*cm, 26 ft.*lbf} for use without union nut wrench

- HINT:

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

|

Using union nut wrench, tighten the injection pipe union nuts on the injector side.

- Torque:

- 32 N*m{326 kgf*cm, 24 ft.*lbf} for use with union nut wrench

- 35 N*m{357 kgf*cm, 26 ft.*lbf} for use without union nut wrench

- HINT:

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

Temporarily install the No. 4 injection pipe with the union nuts.

|

Install 2 new injection pipe clamps with the 2 bolts.

- Torque:

- 13 N*m{133 kgf*cm, 10 ft.*lbf}

- NOTICE:

- Make sure that the inner-rubbers of the injection pipe fit inside the clamps.

- When installing the pipe, check that the inner-rubbers and the clamps are in their proper positions.

Using union nut wrench, tighten the injection pipe union nut on the common rail side.

- Torque:

- 32 N*m{326 kgf*cm, 24 ft.*lbf} for use with union nut wrench

- 35 N*m{357 kgf*cm, 26 ft.*lbf} for use without union nut wrench

- HINT:

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

|

Using union nut wrench, tighten the injection pipe union nut on the injector side.

- Torque:

- 32 N*m{326 kgf*cm, 24 ft.*lbf} for use with union nut wrench

- 35 N*m{357 kgf*cm, 26 ft.*lbf} for use without union nut wrench

- HINT:

- Use a torque wrench with a fulcrum length of 30 cm (11.81 in.).

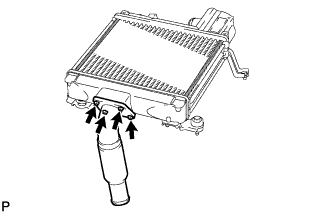

| 5. INSTALL CHARGE AIR COOLER ASSEMBLY WITH INTAKE AIR CONNECTOR |

Install a new gasket and the intake air connector with the 4 bolts.

- Torque:

- 10 N*m{102 kgf*cm, 7 ft.*lbf}

|

Using a 22 mm deep socket wrench, install a new gasket and the IAT sensor.

- Torque:

- 29.4 N*m{300 kgf*cm, 22 ft.*lbf}

|

Install the CAC with the 4 bolts.

- Torque:

- 32 N*m{326 kgf*cm, 24 ft.*lbf} for bolt A

- Torque:

- 12 N*m{122 kgf*cm, 9 ft.*lbf} for bolt B

|

Install a new No. 2 air hose and then tighten the 2 hose clamps.

- Torque:

- 6.5 N*m{66 kgf*cm, 58 in.*lbf}

Tighten the 2 hose clamps of the No. 1 air hose.

- Torque:

- 6.5 N*m{66 kgf*cm, 58 in.*lbf}

Connect the diesel turbo IAT sensor connector.

| 6. INSTALL NO. 1 ENGINE COVER |

|

Install the engine cover with the 3 bolts and 2 nuts.

- Torque:

- 7.0 N*m{71 kgf*cm, 62 in.*lbf}

| 7. ADD FUEL |

| 8. TIGHTEN FUEL TANK CAP ASSEMBLY |

| 9. BLEED AIR FROM FUEL SYSTEM |

|

Using the hand pump, bleed air from the fuel system until pumping becomes difficult.

| 10. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

| 11. REGISTER INJECTOR COMPENSATION CODE |

Register the injector compensation code (Toyota Fortuner RM0000012XK005X.html).

| 12. CHECK FOR FUEL LEAKS |

- CAUTION:

- During Active Test mode, engine speed becomes high and combustion noise becomes loud, so pay attention.

- During Active Test mode, fuel becomes high-pressured. Be extremely careful not to expose your eyes, hands, or body to escaped fuel.

Check that there are no leaks from any part of the fuel system when the engine is stopped. If there is fuel leakage, repair or replace parts as necessary.

Start the engine and check that there are no leaks from any part of the fuel system. If there is fuel leakage, repair or replace parts as necessary.

Disconnect the return hose from the common rail.

Start the engine and check for fuel leaks from the return pipe.

If there is fuel leakage, replace the common rail.

Connect the intelligent tester to the DLC3.

Start the engine and push the intelligent tester main switch on.

Select the Fuel Leak test from the Active Test mode on the intelligent tester.

If the intelligent tester is not available, fully depress the accelerator pedal quickly. Increase the engine speed to the maximum and maintain that speed for 2 seconds. Repeat this operation several times.

Check that there are no leaks from any part of the fuel system.

- NOTICE:

- A return pipe leakage of less than 10 cc (0.6 cu in.) per minute is acceptable.

Reconnect the return hose to the common rail.

| 13. CHECK FOR OIL LEAKS |