Dtc P0488/15 Exhaust Gas Recirculation Throttle Position Control Range / Performance

DESCRIPTION

MONITOR DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK OTHER DTC OUTPUT (IN ADDITION TO DTC P0448/15)

CHECK IF DTC OUTPUT RECURS (DTC P0448/15 OUTPUT)

CHECK ECM (LUSL SIGNAL)

CHECK WIRE HARNESS (THROTTLE CONTROL MOTOR - ECM)

DTC P0488/15 Exhaust Gas Recirculation Throttle Position Control Range / Performance |

DESCRIPTION

The ECM opens and closes the throttle valve using the rotary solenoid type actuator. The exhaust gas recirculation volume is controlled by opening and closing the valve. Also, engine vibration and noise is reduced by closing the valve when the engine is stopped.DTC No.

| DTC Detection Condition

| Trouble Area

|

P0488/15

| When either condition below is met:

- Throttle valve remains closed despite ECM's signal to open valve

(1 trip detection logic)

- Throttle valve remains open despite ECM's signal to close valve

(1 trip detection logic)

| - Throttle valve stuck

- Throttle valve does not move smoothly

- Open or short in throttle valve circuit

- Open or short in throttle valve position sensor circuit

- Throttle position sensor (built in diesel throttle body assembly)

- ECM

|

- HINT:

- After confirming DTC P0488/15, check the throttle position.

- Reference:

Condition

| Throttle Valve Position

|

Moment when accelerator pedal is further depressed or released at 2,500 rpm

| Opening angle varies smoothly

|

MONITOR DESCRIPTION

The ECM opens and closes the throttle valve by adjusting the duration of current flowing to the rotary solenoid (duty ratio). If the throttle valve does not move smoothly or is stuck, the duty ratio during the valve movement control increases or decreases greatly, the ECM will determine that the throttle valve has a malfunction and illuminates the MIL.

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, freeze frame data can help determine if the vehicle was running or stopped, if the engine was warmed up or not, and other data from the time the malfunction occurred.

- After warming up the engine, DTC P0488/15 is set 1 second or more after quickly accelerating the engine from idling.

- NOTICE:

- If the ECM is replaced, the new ECM needs initialization (Toyota Fortuner RM0000012X2005X.html).

| 1.CHECK OTHER DTC OUTPUT (IN ADDITION TO DTC P0448/15) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine / DTC.

Read the DTCs (Toyota Fortuner RM0000012WY00LX.html).

- Result:

Display (DTC Output)

| Proceed to

|

P0488/15

| A

|

P0488/15 and P0120/41, P0122/41 and/or P0123/41

| B

|

- HINT:

- If any other codes besides P0488/15 are output, perform troubleshooting for those DTCs first.

| 2.CHECK IF DTC OUTPUT RECURS (DTC P0448/15 OUTPUT) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine / DTC / Clear.

Clear the DTCs (Toyota Fortuner RM0000012WY00LX.html).

Start the engine and perform a quick engine acceleration from idling to 3,000 rpm 3 times.

Enter the following menus: Powertrain / Engine / DTC.

Read the DTCs (Toyota Fortuner RM0000012WY00LX.html).

- Result:

Display (DTC output)

| Proceed to

|

P0488/15

| A

|

No output

| B

|

- HINT:

- The normal operation of the throttle valve is as follows.

- Reference:

Condition

| Throttle Position

|

Moment when accelerator pedal is further depressed or released at 3,000 rpm

| Opening angle varies smoothly

|

| | CHECK FOR INTERMITTENT PROBLEMS |

|

|

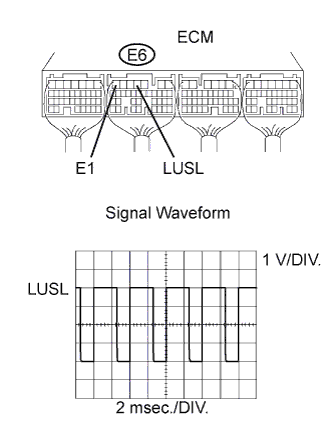

| 3.CHECK ECM (LUSL SIGNAL) |

While revving the engine, check the waveform of the ECM connector using an oscilloscope.

- OK:

Tester Connection

| Specified Condition

|

E6-4 (LUSL) - E6-7 (E1)

| Correct waveform is as shown

|

Tool Setting

| Condition

|

1 V/DIV., 2 msec./DIV.

| Racing engine with warm engine

|

- HINT:

- The waveform varies depending on the diesel throttle signal operation.

| 4.CHECK WIRE HARNESS (THROTTLE CONTROL MOTOR - ECM) |

Disconnect the T2 motor connector.

Disconnect the E6 ECM connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Specified Condition

|

T2-1 (RSO) - E6-4 (LUSL)

| Below 1 Ω

|

T2-1 (RSO) or E6-4 (LUSL) - Body ground

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

| OK |

|

|

|

| REPLACE DIESEL THROTTLE BODY ASSEMBLY |

|