Dtc P0500 Vehicle Speed Sensor Malfunction

DESCRIPTION

MONITOR DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK OPERATION OF SPEEDOMETER

READ VALUE USING INTELLIGENT TESTER (VEHICLE SPEED)

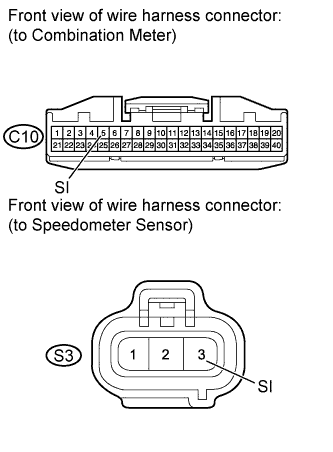

CHECK HARNESS AND CONNECTOR (COMBINATION METER ASSEMBLY - ECM)

CHECK COMBINATION METER ASSEMBLY (+S VOLTAGE)

CHECK COMBINATION METER ASSEMBLY (SPD SIGNAL OUTPUT WAVEFORM)

CHECK COMBINATION METER ASSEMBLY (SPD SIGNAL INPUT WAVEFORM)

CHECK HARNESS AND CONNECTOR (COMBINATION METER - SPEEDOMETER SENSOR)

DTC P0500 Vehicle Speed Sensor Malfunction |

DESCRIPTION

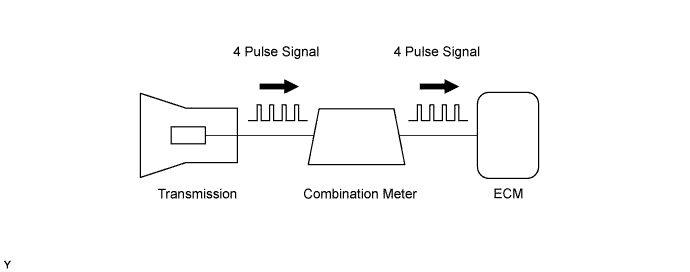

The vehicle speed sensor outputs a 4 pulse signal for every revolution of the rotor shaft, which is rotated by the transmission output shaft via the driven gear. After this signal is converted into a more precise rectangular waveform by the waveform shaping circuit inside the combination meter, it is then transmitted to the ECM. The ECM determines the vehicle speed based on the frequency of these pulse signals.DTC No.

| DTC Detection Condition

| Trouble Area

|

P0500

| While vehicle is being driven, no vehicle speed sensor signal input to ECM

(2 trip detection logic)

| - Open or short in speed sensor circuit

- Vehicle speed sensor

- Combination meter

- ECM

|

MONITOR DESCRIPTION

- for Automatic Transmission

The ECM assumes that the vehicle is being driven when the Park/Neutral Position (PNP) switch is OFF while the vehicle speed signal from the transmission (SP2) indicates a speed of 9 km/h (6 mph) or more. If there is no vehicle speed signal from the combination meter (SP1) for 5 seconds when the vehicle is being driven, the ECM determines this to be a malfunction of the vehicle speed sensor. The ECM then illuminates the MIL and stores the DTC.

- for Manual Transmission

The ECM assumes that the vehicle is being driven when the indicated engine speed is 2000 to 5000 rpm and the engine load calculated by the ECM is more than a certain level. If there is no signal from the vehicle speed sensor, despite these conditions being met, the ECM interprets this as a malfunction in the speed signal circuit. The ECM then illuminates the MIL and stores the DTC.

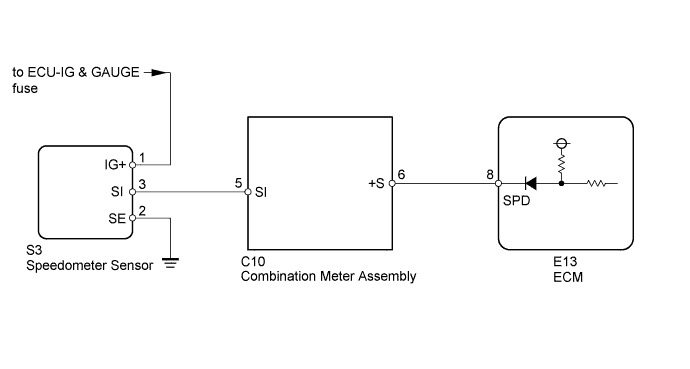

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine conditions when a malfunction is detected. When troubleshooting, freeze frame data can help determine if the vehicle was running or stopped, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

| 1.CHECK OPERATION OF SPEEDOMETER |

Drive the vehicle and check whether the operation of the speedometer in the combination meter is normal.

- HINT:

- The vehicle speed sensor is operating normally if the speedometer reading is normal.

- If the speedometer does not operate, check it by following the procedure described in Speedometer Malfunction.

| 2.READ VALUE USING INTELLIGENT TESTER (VEHICLE SPEED) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON.

Turn the tester on.

Enter the following menus: Powertrain / Engine and ECT / Data List / All Data / Vehicle Speed.

Drive the vehicle.

Read the value displayed on the tester.

- OK:

- Vehicle speeds displayed on tester and speedometer display are equal.

| 3.CHECK HARNESS AND CONNECTOR (COMBINATION METER ASSEMBLY - ECM) |

Disconnect the combination meter connector.

Disconnect the ECM connector.

Measure the resistance according the value(s) in the table below.

- Standard resistance:

Tester Connection

| Specified Condition

|

C10-6 (S+) - E13-8 (SPD)

| Below 1 Ω

|

C10-6 (S+) or E13-8 (SPD) - Body ground

| 10 kΩ or higher

|

- HINT:

- If the wire has a short, check the speed signal circuit in other systems related to the vehicle speed signal (e.g. tire pressure warning system, audio system, etc.).

| | REPAIR OR REPLACE HARNESS OR CONNECTOR (OTHER SYSTEM RELATED TO SPEED METER) |

|

|

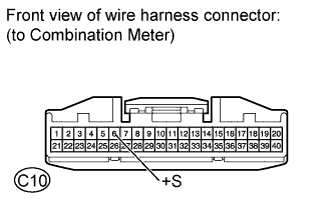

| 4.CHECK COMBINATION METER ASSEMBLY (+S VOLTAGE) |

Disconnect the combination meter connector.

- HINT:

- Disconnect the ECU connectors on the other systems related to the speed signal (but the ECM connectors must be connected).

Turn the ignition switch to ON.

Measure the voltage according to the value(s) in the table below.

- Standard voltage:

Tester Connection

| Condition

| Specified Condition

|

C10-6 (+S) - Body ground

| Ignition switch on

| 4.5 to 5.5 V

|

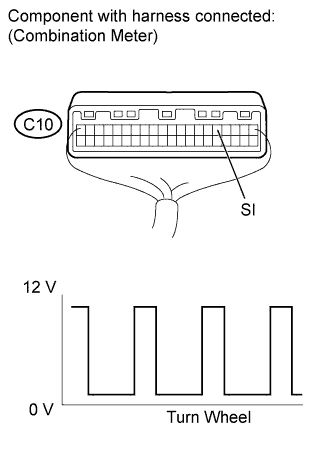

| 5.CHECK COMBINATION METER ASSEMBLY (SPD SIGNAL OUTPUT WAVEFORM) |

Remove the combination meter assembly.

Connect the combination meter connector.

Move the shift lever to the neutral position.

Jack up one of the rear wheels.

Turn the ignition switch to ON.

Check the voltage between the terminal of the combination meter and the body ground while the rear wheel is turned slowly.

- Standard voltage:

Tester Connection

| Condition

| Specified Condition

|

C10-6 (+S) - Body ground

| Ignition switch on

Turn wheel slowly

| Voltage generated intermittently

|

- HINT:

- The output voltage should fluctuate up and down, similarly to the diagram, when the wheel is turned slowly.

- A voltage of 12 V or 5 V is output from each ECU and then input to the combination meter assembly.

- HINT:

- The output voltage should fluctuate up and down, similarly to the diagram, when the wheel is turned slowly.

| 6.CHECK COMBINATION METER ASSEMBLY (SPD SIGNAL INPUT WAVEFORM) |

Remove the combination meter assembly.

Connect the combination meter connector.

Move the shift lever to the neutral position.

Jack up one of the rear wheels.

Turn the ignition switch to ON.

Check the voltage between the terminal of the combination meter and the body ground while the rear wheel is turned slowly.

- Standard voltage:

Tester Connection

| Condition

| Specified Condition

|

C10-5 (SI) - Body ground

| Ignition switch on

Turn wheel slowly

| Voltage generated intermittently

|

- HINT:

- The output voltage should fluctuate up and down, similarly to the diagram, when the wheel is turned slowly.

| 7.CHECK HARNESS AND CONNECTOR (COMBINATION METER - SPEEDOMETER SENSOR) |

Disconnect the combination meter connector.

Disconnect the speedometer sensor connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

C10-5 (SI) - S3-3 (SI)

| Always

| Below 1 Ω

|

C10-5 (SI) or S3-3 (SI) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| OK |

|

|

|

| REPLACE SPEEDOMETER SENSOR |

|