Meter / Gauge System Tachometer Malfunction

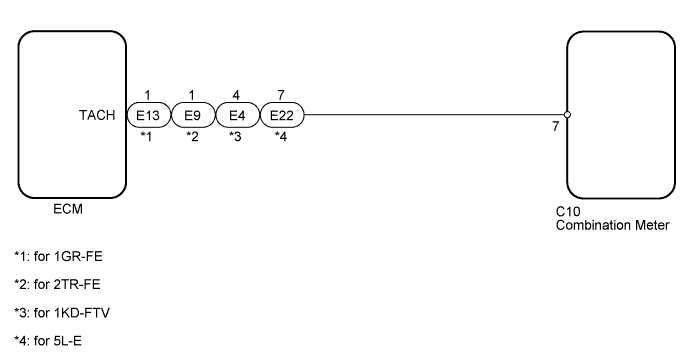

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK COMBINATION METER ASSEMBLY

CHECK WIRE HARNESS (METER - ECM)

METER / GAUGE SYSTEM - Tachometer Malfunction |

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.CHECK COMBINATION METER ASSEMBLY |

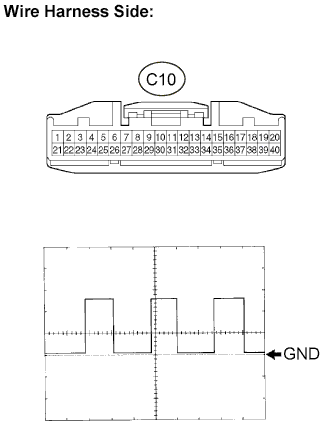

Disconnect the C10 meter connector.

Using an oscilloscope, check the signal waveform of the meter.

Tester Connection

| Tool Setting

| Vehicle Condition

|

C10-7 - Body ground

| 5 V/DIV., 10 msec./DIV.

| Engine idling

|

- OK:

- Refer to the illustration.

- HINT:

- As the engine speed increases, the wavelength shortens.

| | REPLACE COMBINATION METER ASSEMBLY |

|

|

| 2.CHECK WIRE HARNESS (METER - ECM) |

Disconnect the C10 meter connector.

Disconnect the E13*1, E9*2, E4*3 or E22*4 ECM connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

for 1GR-FETester Connection

| Specified Condition

|

C10-7 - E13-1 (TACH)

| Below 1 Ω

|

C10-7 - Body ground

| 10 kΩ or higher

|

- for 2TR-FE:

Tester Connection

| Specified Condition

|

C10-7 - E9-1 (TACH)

| Below 1 Ω

|

C10-7 - Body ground

| 10 kΩ or higher

|

- for 1KD-FTV:

Tester Connection

| Specified Condition

|

C10-7 - E4-4 (TACH)

| Below 1 Ω

|

C10-7 - Body ground

| 10 kΩ or higher

|

- for 5L-E:

Tester Connection

| Specified Condition

|

C10-7 - E22-7 (TACH)

| Below 1 Ω

|

C10-7 - Body ground

| 10 kΩ or higher

|

Result Result

| Proceed to

|

OK (1GR-FE, 2TR-FE)

| A

|

OK (1KD-FTV, 5L-E)

| B

|

NG

| C

|

| |

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|