Dtc P0504/51 Brake Switch A / B Correlation

DESCRIPTION

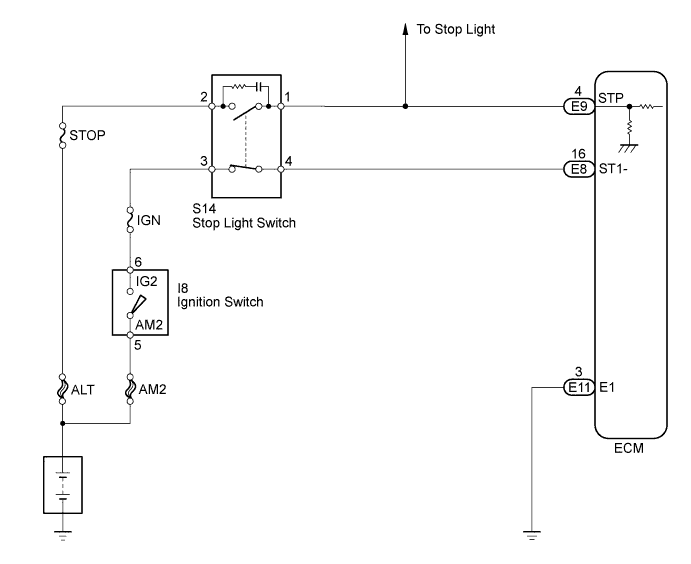

WIRING DIAGRAM

INSPECTION PROCEDURE

When using intelligent tester:

CHECK STOP LIGHT (OPERATION)

READ DATA LIST (STP SIGNAL, ST1- VOLTAGE)

INSPECT STOP LIGHT SWITCH ASSEMBLY

CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH - ECM)

When not using intelligent tester:

CHECK STOP LIGHT (OPERATION)

CHECK ECM (STP, ST1- VOLTAGE)

INSPECT STOP LIGHT SWITCH ASSEMBLY

CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH - ECM)

DTC P0504/51 Brake Switch "A" / "B" Correlation |

DESCRIPTION

In this system, the signals of the stop light switch's duplex system (STP and ST1-) are used to judge whether the brake system is abnormal or not. When the signals of depressing and releasing the brake pedal are detected simultaneously, the ECM interprets this as a malfunction of the stop light switch.- HINT:

- The normal signal conditions are as shown in the table below.

Signal (ECM Terminal)

| Brake Pedal Released

| In Transition

| Brake Pedal Depressed

|

STP

| OFF

| ON

| ON

|

ST1-

| ON

| ON

| OFF

|

- [OFF] denotes ground potential.

- [ON] denotes battery potential (+B).

- On the intelligent tester, the Data List items Stop Light Switch and ST1 are both ON when the brake pedal is depressed because the characteristics of ST1 indication are the opposite of the characteristics of Stop Light Switch indication.

DTC No.

| DTC Detection Condition

| Trouble Area

|

P0504/51

| Conditions (a), (b) and (c) continue for 0.5 seconds or more:

- (a) Ignition switch ON

- (b) Brake pedal released

- (c) STP signal is OFF when ST1- signal is OFF

| - Short in stop light switch signal circuit

- STOP fuse

- Stop light switch

- ECM

|

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine conditions when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air-fuel ratio was lean or rich, and other data from the time the malfunction occurred.

When using intelligent tester:

- HINT:

- Stop light switch conditions can be checked using the intelligent tester.

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch to ON.

- Turn the intelligent tester on.

- Enter the following menus: Powertrain / Engine and ECT / Data List / All Data / Stop Light Switch and ST1.

- Check the Data List indication when the brake pedal is depressed and released.

Brake Pedal Operation

| Stop Light Switch

| ST1

|

Depressed

| ON

| ON

|

Released

| OFF

| OFF

|

| 1.CHECK STOP LIGHT (OPERATION) |

Check that the stop lights turn ON and OFF when the brake pedal is depressed and released, respectively.

- OK:

- Stop lights turn ON and OFF when brake pedal is depressed and released, respectively.

| | REPAIR OR REPLACE STOP LIGHT SWITCH CIRCUIT |

|

|

| 2.READ DATA LIST (STP SIGNAL, ST1- VOLTAGE) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch ON and turn the intelligent tester ON.

Enter the following menus: Powertrain / Engine and ECT / Data List / Stop Light Switch.

Check the STP signal when depressing and releasing the brake pedal.

- OK:

Brake Pedal Condition

| Specified Condition

|

Depressed

| STP Signal ON

|

Released

| STP Signal OFF

|

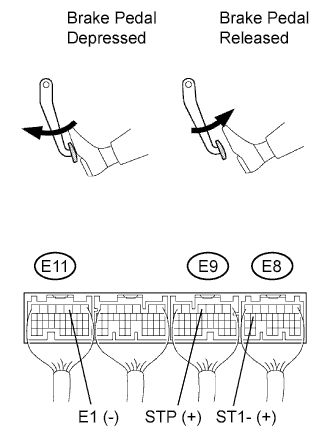

Measure the voltage of the ECM connectors.

- Standard voltage:

Tester Connection

| Brake Pedal Condition

| Specified Condition

|

E8-16 (ST1-) - E11-3 (E1)

| Depressed

| Below 1.5 V

|

E8-16 (ST1-) - E11-3 (E1)

| Released

| 7.5 to 14 V

|

| | CHECK FOR INTERMITTENT PROBLEMS |

|

|

| 3.INSPECT STOP LIGHT SWITCH ASSEMBLY |

Measure the resistance of the switch.

- Standard resistance:

Tester Connection

| Switch Condition

| Specified Condition

|

1 - 2

| Pin not pushed

| Below 1 Ω

|

3 - 4

| Pin not pushed

| 10 kΩ or higher

|

1 - 2

| Pin pushed

| 10 kΩ or higher

|

3 - 4

| Pin pushed

| Below 1 Ω

|

| | REPLACE STOP LIGHT SWITCH ASSEMBLY |

|

|

| 4.CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH - ECM) |

Disconnect the E8 and E9 ECM connectors.

Disconnect the S14 stop light switch connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Specified Condition

|

S14-1 - E9-4 (STP)

| Below 1 Ω

|

S14-4 - E8-16 (ST1-)

| Below 1 Ω

|

S14-1 or E9-4 (STP) - Body ground

| 10 kΩ or higher

|

S14-4 or E8-16 (ST1-) - Body ground

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

When not using intelligent tester:

| 1.CHECK STOP LIGHT (OPERATION) |

Check that the stop lights turn ON and OFF when the brake pedal is depressed and released, respectively.

- OK:

- Stop lights turn ON and OFF when brake pedal is depressed and released, respectively.

| | REPAIR OR REPLACE STOP LIGHT SWITCH CIRCUIT |

|

|

| 2.CHECK ECM (STP, ST1- VOLTAGE) |

Turn the ignition switch ON.

Measure the voltage of the ECM connectors.

- Standard voltage:

Tester Connection

| Brake Pedal Condition

| Specified Condition

|

E9-4 (STP) - E11-3 (E1)

| Depressed

| 7.5 to 14 V

|

E9-4 (STP) - E11-3 (E1)

| Released

| Below 1.5 V

|

E8-16 (ST1-) - E11-3 (E1)

| Depressed

| Below 1.5 V

|

E8-16 (ST1-) - E11-3 (E1)

| Released

| 7.5 to 14 V

|

| | CHECK FOR INTERMITTENT PROBLEMS |

|

|

| 3.INSPECT STOP LIGHT SWITCH ASSEMBLY |

Measure the resistance of the switch.

- Standard resistance:

Tester Connection

| Switch Condition

| Specified Condition

|

1 - 2

| Pin not pushed

| Below 1 Ω

|

3 - 4

| Pin not pushed

| 10 kΩ or higher

|

1 - 2

| Pin pushed

| 10 kΩ or higher

|

3 - 4

| Pin pushed

| Below 1 Ω

|

| | REPLACE STOP LIGHT SWITCH ASSEMBLY |

|

|

| 4.CHECK HARNESS AND CONNECTOR (STOP LIGHT SWITCH - ECM) |

Disconnect the E8 and E9 ECM connectors.

Disconnect the S14 stop light switch connector.

Measure the resistance of the wire harness side connectors.

- Standard resistance:

Tester Connection

| Specified Condition

|

S14-1 - E9-4 (STP)

| Below 1 Ω

|

S14-4 - E8-16 (ST1-)

| Below 1 Ω

|

S14-1 or E9-4 (STP) - Body ground

| 10 kΩ or higher

|

S14-4 or E8-16 (ST1-) - Body ground

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|