Dtc C1241 Low Power Supply Voltage Malfunction

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK TERMINAL VOLTAGE (IG1 TERMINAL)

CHECK HARNESS AND CONNECTOR (GND1 TERMINAL)

RECONFIRM DTC

DTC C1241 Low Power Supply Voltage Malfunction |

DESCRIPTION

If a malfunction is detected in the power supply circuit, the skid control ECU (brake actuator assembly) stores this DTC and the fail-safe function prohibits brake control operation.This DTC is stored when the IG1 terminal voltage drops below the threshold due to a malfunction in the power supply or charging circuit, such as the battery or generator circuit, etc.The DTC is cleared when the IG1 terminal voltage returns to normal.DTC Code

| DTC Detection Condition

| Trouble Area

|

C1241

| One of the following conditions is met:

- At a vehicle speed of 3 km/h (2 mph) or more, the IG1 terminal voltage is below 9.5 V for 10 seconds or more.

- When the solenoid relay remains on and the IG1 terminal voltage is below 9.5 V, the relay contact is open for 0.22 seconds or more.

- With the IG1 terminal voltage at 9.5 V or less, the vehicle speed sensor power supply decreases for 60 seconds or more.

- When the motor relay and fail-safe relay are on, the voltage at terminal IG1 is below 9.5 V and the actuator pump motor is off for 0.2 seconds or more.

| - ECU-IG NO. 2 fuse

- Battery

- Charging system

- Power source circuit

- Internal power supply circuit of skid control ECU (Brake actuator assembly)

|

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- After replacing the brake actuator assembly, perform calibration (Toyota Fortuner RM000000XHR06WX.html).

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

- Before disconnecting the connector, make sure that there are no problems with the connection.

- After disconnecting the connector, make sure that the connector case and terminals are not deformed or corroded.

| 1.CHECK TERMINAL VOLTAGE (IG1 TERMINAL) |

Turn the ignition switch off.

Disconnect the skid control ECU (brake actuator assembly) connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Switch Condition

| Specified Condition

|

S25-34 (IG1) - Body ground

| Ignition switch ON

| 11 to 14 V

|

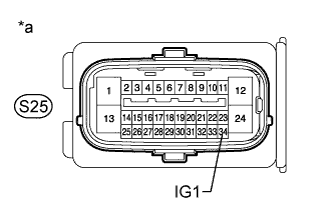

Text in Illustration*a

| Front view of wire harness connector

(to Skid Control ECU [Brake Actuator Assembly])

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 2.CHECK HARNESS AND CONNECTOR (GND1 TERMINAL) |

Turn the ignition switch off.

Disconnect the skid control ECU (brake actuator assembly) connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

S25-1 (GND1) - Body ground

| Always

| Below 1 Ω

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

Clear the DTC (Toyota Fortuner RM000000XHV0C7X.html).

Turn the ignition switch off.

Start the engine.

Drive the vehicle at a speed of 20 km/h (12 mph) or more for 30 seconds or more.

Check if the same DTC is output (Toyota Fortuner RM000000XHV0C7X.html).

ResultResult

| Proceed to

|

DTC is not output

| A

|

DTC is output

| B

|

- HINT:

- If troubleshooting has been carried out according to Problem Symptoms Table, refer back to the table and proceed to the next suspected area (Toyota Fortuner RM000000XHN0BDX.html).