Fuel Injector (For Hatchback) -- Inspection |

| 1. INSPECT FUEL INJECTOR ASSEMBLY |

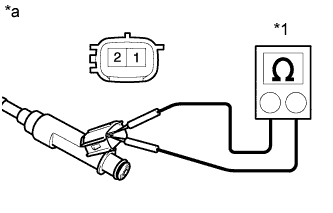

Check the resistance.

Text in Illustration *1 Ohmmeter *a Component without harness connected

(Fuel Injector Assembly)Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection Condition Specified Condition 1 - 2 20°C (68°F) 11.6 to 12.4 Ω

|

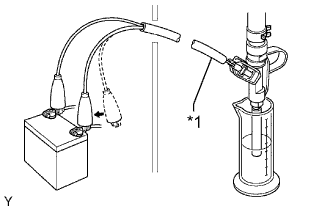

Check the operation.

- CAUTION:

- Perform the inspection in a well-ventilated area.

- Do not perform the inspection near any open flames.

Connect SST (fuel tube connector) to SST (hose), and then connect them to the fuel pipe (vehicle side).

Text in Illustration *1 Fuel Pipe *2 SST (Clip) *3 SST (Fuel Tube Connector) *4 SST (Hose) - SST

- 09268-31013(90467-13001,95336-08070,09268-41500)

Install the new O-ring onto the fuel injector.

Text in Illustration *1 SST (Clip) *2 SST (Adapter) *3 SST (Hose) *4 O-Ring *5 SST (Clamp) *6 Vinyl Tube - SST

- 09268-31013(95336-08070,09268-41300,09268-41110)

Connect SST (adapter and hose) to the injector, and hold the injector and union with SST (clamp).

Put the injector into a graduated cylinder.

- CAUTION:

- Install a suitable vinyl tube onto the injector assembly to prevent gasoline splashes.

Operate the fuel pump (YARIS_NCP93 RM000000SXS05AX.html).

Connect SST (wire) to the injector assembly and the battery for 15 seconds, and measure the injection volume with the graduated cylinder. Test each injector 2 or 3 times.

- SST

- 09842-30080

- Injection Volume:

Tester Connection Condition Specified Condition Positive terminal - Ground terminal Per 15 seconds 47 to 58 cm3 (2.9 to 3.5 cu in.)

Text in Illustration *1 SST (Wire)

Connect - Difference between each injector:

- 11 cm3 (0.7 cu in.) or less

- CAUTION:

- Always do the switching at the battery side.

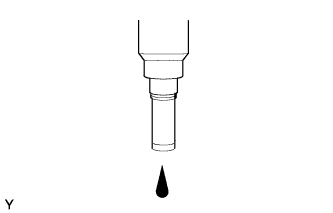

Check for leaks.

In the condition above, disconnect the test probes of SST (wire) from the battery and check if the fuel leaks from the injector.

- Fuel Drop:

- 1 drop or less every 12 minutes

|