Camshaft (For Hatchback) Removal

REMOVE ENGINE UNDER COVER RH

REMOVE NO. 2 CYLINDER HEAD COVER

DISCONNECT VENTILATION HOSE

DISCONNECT FUEL VAPOR FEED HOSE ASSEMBLY

REMOVE NO. 1 IGNITION COIL

REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY

REMOVE ENGINE MOUNTING INSULATOR SUB-ASSEMBLY RH

REMOVE NO. 2 CAMSHAFT

REMOVE CAMSHAFT

REMOVE CAMSHAFT TIMING GEAR ASSEMBLY

Camshaft (For Hatchback) -- Removal |

| 1. REMOVE ENGINE UNDER COVER RH |

| 2. REMOVE NO. 2 CYLINDER HEAD COVER |

Remove the 4 nuts and No. 2 cylinder head cover.

| 3. DISCONNECT VENTILATION HOSE |

Disconnect the ventilation hose.

| 4. DISCONNECT FUEL VAPOR FEED HOSE ASSEMBLY |

Disconnect the fuel vapor feed hose assembly.

| 5. REMOVE NO. 1 IGNITION COIL |

Disconnect the 4 No. 1 ignition coil connectors.

Remove the 4 bolts and the 4 No. 1 ignition coils.

| 6. REMOVE CYLINDER HEAD COVER SUB-ASSEMBLY |

Disconnect the fuel injector connectors.

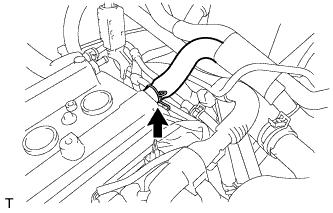

Disconnect the connector and 3 wire harness clamps shown in the illustration and disconnect the engine wire harness.

Remove the bolt and remove the wire harness bracket.

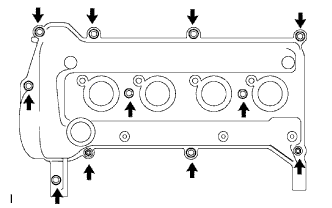

Remove the 9 bolts, 2 nuts and 2 seal washers and then remove the cylinder head cover sub-assembly.

Remove the gasket from the cylinder head cover sub-assembly.

| 7. REMOVE ENGINE MOUNTING INSULATOR SUB-ASSEMBLY RH |

Place a wooden block on a jack underneath the engine.

Remove the 4 bolts, 2 nuts and the engine mounting insulator sub-assembly RH.

Text in Illustration*a

| Alignment Mark

|

- NOTICE:

- When rotating the camshaft with the timing chain removed, rotate the crankshaft damper counterclockwise 40 ° from the TDC and align the timing notch with the alignment mark of the timing chain cover to prevent the pistons from coming into contact with the valves.

Set the No. 1 cylinder to TDC/compression.

Turn the crankshaft damper, and align the timing notch with the timing mark "0" of the oil pump.

Text in Illustration*a

| Timing Notch

|

Check that both timing marks on the camshaft timing sprocket and camshaft timing gear are facing upward, as shown in the illustration.

Text in Illustration*a

| Timing Mark

|

- HINT:

- If not, turn the crankshaft 1 complete revolution (360°) and align the marks as above.

Place paint marks on the chain where it touches the timing marks on the camshaft timing sprocket and the camshaft timing gear.

Text in Illustration*a

| Paint Mark

|

*b

| Timing Mark

|

Using an 8 mm (0.31 in.) hexagon wrench, remove the screw plug.

Insert a screwdriver into the service hole in the chain tensioner to pull the stopper plate of the chain tensioner upward.

Text in Illustration*1

| Stopper Plate

|

Using a wrench, rotate the No. 2 camshaft clockwise to push in the plunger of the chain tensioner.

Text in Illustration*1

| Plunger

|

Remove the screwdriver from the service hole, then align the hole the stopper plate with the service hole and insert a 3 mm (0.12 in.) diameter bar into the holes to hold the stopper plate.

- HINT:

- Fix the stopper plate using the bar while rotating the camshaft right and left slightly.

- Hold the bar with tape so that the bar does not come off.

Using a wrench, hold the hexagonal lobe of the No. 2 camshaft and remove the flange bolt.

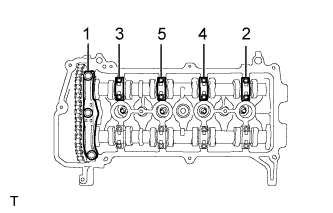

Using several steps, loosen and remove the 11 bearing cap bolts uniformly in the sequence shown in the illustration, then remove the No. 1 and No. 2 camshaft bearing caps.

- NOTICE:

- Loosen the bolts uniformly while keeping the camshaft level.

Remove the flange bolt and the camshaft timing sprocket.

Remove the No. 2 camshaft.

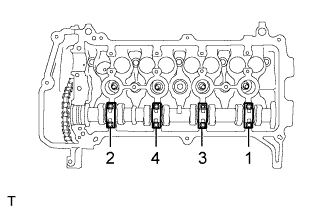

Using several steps, loosen and remove the 8 bearing cap bolts uniformly in the sequence shown in the illustration, then remove the No. 2 camshaft bearing cap.

- NOTICE:

- Loosen each bolt uniformly while keeping the camshaft level.

Hold the chain by hand, and remove the camshaft and the camshaft timing gear assembly.

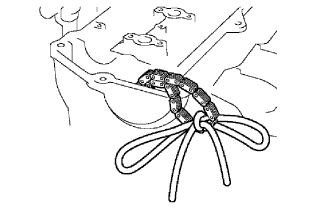

Tie the chain with a piece of string as shown in the illustration.

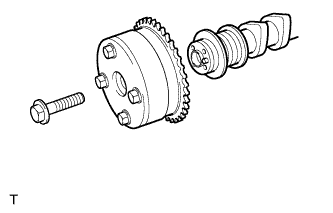

| 10. REMOVE CAMSHAFT TIMING GEAR ASSEMBLY |

Clamp the camshaft in a vise and confirm that it is locked.

- NOTICE:

- Do not damage the camshaft.

Cover the 4 oil paths of the cam journal with tape as shown in the illustration.

Text in Illustration*1

| Rubber Piece

|

*2

| Vinyl Tape

|

*a

| Advance Side Path

|

*b

| Retard Side Path

|

*c

| Open

|

*d

| Close

|

- HINT:

- One of the 2 grooves located on the cam journal is for retarding cam timing (upper) and the other is for advancing cam timing (lower). Each groove has 2 oil paths. Plug one of the oil paths for each groove with a piece of rubber before wrapping the cam journal with the tape.

Puncture the tape covering the advance oil path and the retard oil path on the opposite side from the advance oil path.

Apply air at about 150 kPa (1.5 kgf/cm2) pressure into the 2 broken paths (the advance side path and the retard side path).

Text in Illustration*a

| Advance Side Path

|

*b

| Retard Side Path

|

- NOTICE:

- Cover the paths with a piece of cloth to prevent oil splashes.

Confirm that the camshaft timing gear assembly revolves in the timing advance direction when the air pressure on the timing retard path is reduced.

Text in Illustration*a

| Advance Side Path

|

*b

| Retard Side Path

|

*c

| Hold Pressure

|

*d

| Decompress

|

- HINT:

- The lock pin is released, and the camshaft timing gear revolves in the advance direction.

When the camshaft timing gear reaches the most advanced position, release the air pressure on the timing retard side path, and then release the air pressure on the timing advance side path.

- NOTICE:

- The camshaft timing gear assembly occasionally shifts to the retard side abruptly, if the air pressure on the advance side path is released first. This often results in the breakage of the lock pin.

Remove the flange bolt and the camshaft timing gear assembly.

- NOTICE:

- Do not remove the other 4 bolts.

- When reusing the camshaft timing gear, unlock the lock pin inside the camshaft timing gear first.