Lighting System (For Hatchback) High Beam Headlight Circuit

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

PERFORM ACTIVE TEST USING TECHSTREAM

INSPECT HEADLIGHT DIMMER RELAY (DIM RELAY)

CHECK HARNESS AND CONNECTOR (HEADLIGHT DIMMER RELAY - BATTERY)

CHECK HARNESS AND CONNECTOR (HEADLIGHT DIMMER RELAY - INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY)

INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY

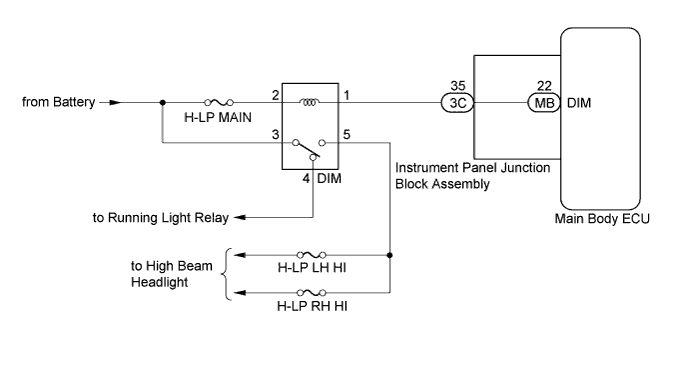

LIGHTING SYSTEM (for Hatchback) - High Beam Headlight Circuit |

DESCRIPTION

The main body ECU controls the high beam headlights.

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

| 1.PERFORM ACTIVE TEST USING TECHSTREAM |

Connect the Techstream to the DLC3.

Turn the ignition switch to ON.

Turn the Techstream on.

Enter the following menus: Body Electrical / Main Body / Active Test.

According to the display on the Techstream, perform the Active Test.

Main BodyTester Display

| Test Part

| Control Range

| Diagnostic Note

|

Head Light Hi

| Headlight dimmer relay

| OFF or ON

| -

|

- OK:

- Headlight dimmer relay operates (High beam headlight illuminate.)

| 2.INSPECT HEADLIGHT DIMMER RELAY (DIM RELAY) |

Inspect the headlight dimmer relay (DIM relay) (YARIS_NCP93 RM000001Y5C00VX.html).

| | REPLACE HEADLIGHT DIMMER RELAY (DIM RELAY) |

|

|

| 3.CHECK HARNESS AND CONNECTOR (HEADLIGHT DIMMER RELAY - BATTERY) |

Remove the headlight dimmer relay (DIM relay) from the No. 2 engine room relay block.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Condition

| Specified Condition

|

DIM-2 - Body ground

| Always

| 11 to 14 V

|

DIM-3 - Body ground

| Always

| 11 to 14 V

|

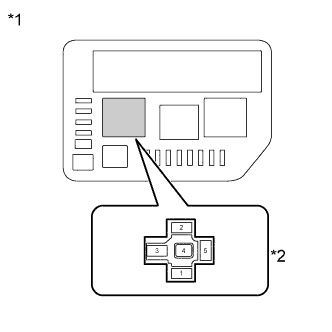

Text in Illustration*1

| No. 2 Engine Room Relay Block

|

*2

| Headlight Dimmer Relay (DIM Relay) Holder

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 4.CHECK HARNESS AND CONNECTOR (HEADLIGHT DIMMER RELAY - INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY) |

Remove the headlight dimmer relay (DIM relay) from the No. 2 engine room relay block.

Disconnect the 3C instrument panel junction block assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

DIM-1 - 3C-35

| Always

| Below 1 Ω

|

DIM-1 - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 5.INSPECT INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

Remove the instrument panel junction block assembly.

Remove the main body ECU from the instrument panel junction block assembly.

Measure the resistance according to the value(s) in the table below.

Text in Illustration*a

| Component without harness connected

(Instrument Panel Junction Block Assembly)

| -

| -

|

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

3C-35 - MB-22 (DIM)

| Always

| Below 1 Ω

|

| | REPLACE INSTRUMENT PANEL JUNCTION BLOCK ASSEMBLY |

|

|