CHECK CONTINUOUSLY VARIABLE VALVE LIFT CONTROLLER ASSEMBLY (POWER SOURCE)

CHECK HARNESS AND CONNECTOR (CONTINUOUSLY VARIABLE VALVE LIFT CONTROLLER - ECM)

REPLACE CONTINUOUSLY VARIABLE VALVE LIFT CONTROLLER ASSEMBLY

DTC U011B Lost Communication with Rocker Arm Control Module "A" |

DESCRIPTION

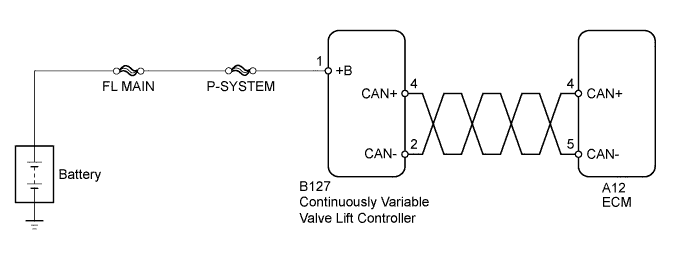

The ECM and continuously variable valve lift controller assembly send signals via CAN communication. When there is a malfunction in the CAN communication, a DTC is stored and the MIL illuminates.| DTC No. | DTC Detection Condition | Trouble Area |

| U011B | CAN communication stops (1 trip detection logic). |

|

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- When one of the following DTCs is stored and the MIL is illuminated, DTC P1047 is stored and actuator position learning is performed every time the engine is started. Also, after the system returns to normal, the following occurs during the first driving cycle: 1) DTC P1047 is stored, 2) actuator position learning is performed and 3) the MIL illuminates during actuator position learning.

| Actuator position learning is performed when these DTCs are stored. |

| P1046, P1049, P104A, P1055, P2646, P2647, P2648, P2649, P264A, U011B |

- HINT:

- When there is no power (+B) supplied to the continuously variable valve lift controller assembly, DTC U011B is stored. After the continuously variable valve lift controller assembly power supply system and communication lines have been connected or repaired, actuator position learning is performed and DTC P1047 is stored the next time the vehicle is driven.

- After performing repairs, perform the following procedures and check that DTCs are not output again.

- Connect the intelligent tester to the DLC3.

- Start the engine and warm it up.

- Turn the tester on.

- Clear the DTCs (RAV4_ACA30 RM000000PDK0BLX.html).

- Turn the ignition switch off and wait 10 seconds.

- Start the engine and idle it for 20 seconds.

- Clear the DTCs (RAV4_ACA30 RM000000PDK0BLX.html).

- Turn the ignition switch off and wait 10 seconds.

- Start the engine and idle it for 20 seconds.

- Turn the ignition switch off and wait 10 seconds.

- Turn the ignition switch to ON.

- Enter the following menus: Powertrain / Engine and ECT / DTC.

- Read the DTCs.

- NOTICE:

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

| 1.CHECK CONTINUOUSLY VARIABLE VALVE LIFT CONTROLLER ASSEMBLY (POWER SOURCE) |

Disconnect the continuously variable valve lift controller assembly connector.

|

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

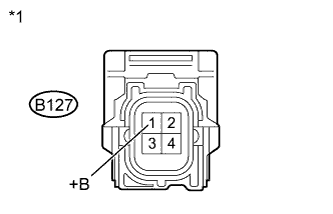

Tester Connection Switch Condition Specified Condition B127-1 (+B) - Body ground Ignition switch ON 11 to 14 V

Text in Illustration *1 Component without harness connected

(Continuously Variable Valve Lift Controller)

Reconnect the continuously variable valve lift controller assembly connector.

|

| ||||

| OK | |

| 2.CHECK HARNESS AND CONNECTOR (CONTINUOUSLY VARIABLE VALVE LIFT CONTROLLER - ECM) |

Disconnect the continuously variable valve lift controller assembly connector.

Disconnect the ECM connector.

|

Measure the resistance according to the value(s) in the table below.

- Standard Resistance (Check for Open):

Tester Connection Switch Condition Specified Condition B127-4 (CAN+) - A12-4 (CAN+) Ignition switch off Below 1 Ω B127-2 (CAN-) - A12-5 (CAN-) Ignition switch off Below 1 Ω

- Standard Resistance (Check for Short):

Tester Connection Switch Condition Specified Condition B127-4 (CAN+) or A12-4 (CAN+) - Body ground Ignition switch off 10 kΩ or higher B127-2 (CAN-) or A12-5 (CAN-) - Body ground Ignition switch off 10 kΩ or higher

Text in Illustration *1 Front view of wire harness connector

(to Continuously Variable Valve Lift Controller)*2 Front view of wire harness connector

(to ECM)

Reconnect the ECM connector.

Reconnect the continuously variable valve lift controller assembly connector.

|

| ||||

| OK | |

| 3.REPLACE CONTINUOUSLY VARIABLE VALVE LIFT CONTROLLER ASSEMBLY |

Replace the continuously variable valve lift controller assembly (RAV4_ACA30 RM0000036Y4008X.html).

| NEXT | |

| 4.PERFORM SIMULATION TEST |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON.

Turn the tester on.

Clear the DTC.

Perform a simulation test.

Turn the ignition switch to ON and wait 5 seconds

Start the engine and idle it for 5 seconds.

Turn the ignition switch off and wait 5 seconds

Turn the ignition switch to ON.

Turn the tester on.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read the DTCs.

Result Result Proceed to DTC U011B is output A DTC is not output B

|

| ||||

| A | ||

| ||