Dtc P0741 Torque Converter Clutch Solenoid Performance (Shift Solenoid Valve Dsl)

DESCRIPTION

MONITOR DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK OTHER DTC OUTPUT (IN ADDITION TO DTC P0741)

INSPECT TRANSMISSION WIRE (SHIFT SOLENOID VALVE DSL)

CHECK WIRE HARNESS (TRANSMISSION WIRE - ECM)

INSPECT SHIFT SOLENOID VALVE DSL

CHECK TRANSMISSION WIRE

INSPECT TRANSMISSION VALVE BODY ASSEMBLY

INSPECT TORQUE CONVERTER CLUTCH ASSEMBLY

DTC P0741 Torque Converter Clutch Solenoid Performance (Shift Solenoid Valve DSL) |

DESCRIPTION

The ECM uses the signals from the throttle position sensor, air-flow meter, turbine (input) speed sensor, intermediate (counter) shaft speed sensor and crankshaft position sensor to monitor the engagement condition of the lock-up clutch.Then the ECM compares the engagement conditions of the lock-up clutch with the lock-up schedule in the ECM memory to detect mechanical problems of the shift solenoid valve DSL, valve body and torque converter clutch.DTC No.

| DTC Detection Condition

| Trouble Area

|

P0741

| Lock-up does not occur when driving in lock-up range

Lock-up remains ON in lock-up OFF range

(2 trip detection logic)

| - Shift solenoid valve DSL remains open or closed

- Valve body is blocked

- Shift solenoid valve DSL

- Torque converter clutch

- Automatic transaxle (clutch, brake, gear, etc.)

- Line pressure is too low

- ECM

|

MONITOR DESCRIPTION

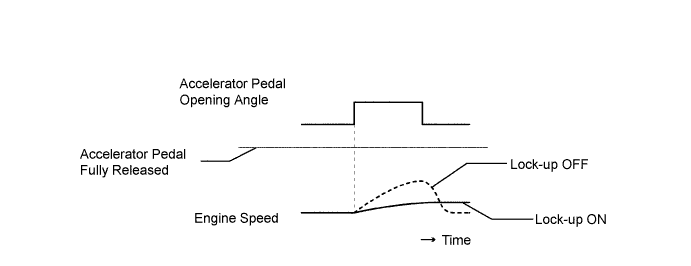

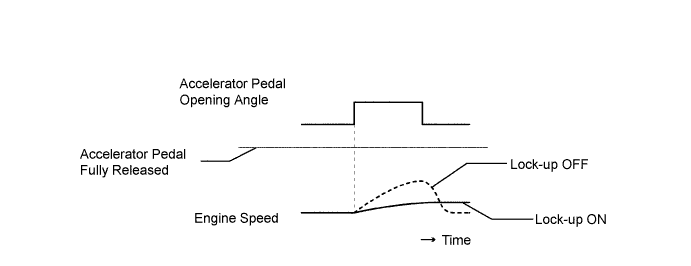

Torque converter lock-up is controlled by the ECM based on the speed sensor (NT), speed sensor (NC), engine rpm, engine load, engine temperature, vehicle speed, transmission temperature and gear selection.The ECM determines the lock-up status of the torque converter by comparing the engine rpm (NE) to the input turbine rpm (NT). The ECM calculates the actual transmission gear by comparing input turbine rpm control voltage to counter gear rpm (NC). When conditions are appropriate, the ECM requests "lock-up" by applying control voltage to the shift solenoid valve DSL. When the DSL is turned on, it applies pressure to the lock-up relay valve and locks the torque converter clutch.If the ECM detects no lock-up after lock-up has been requested or if it detects lock-up when it is not requested, the ECM interprets this as a fault in the shift solenoid valve DSL or lock-up system performance.The ECM will illuminate the MIL and store the DTC.Example: When any of the following is met, the system judges it as a malfunction.- There is a difference in rotation between the input side (engine speed) and output side (input turbine speed) of the torque converter when the ECM commands lock-up.

(Engine speed is at least 100 rpm greater than input turbine speed.)

- There is no difference in rotation between the input side (engine speed) and output side (input turbine speed) of the torque converter when the ECM commands lock-up OFF.

(The difference between engine speed and input turbine speed is less than 35 rpm.)

WIRING DIAGRAM

INSPECTION PROCEDURE

- HINT:

- Performing the intelligent tester's Active Test allows relay, VSV, actuator and other items to be operated without removing any parts. Performing the Active Test early in troubleshooting is one way to save time.

- The Data List can be displayed during the Active Test.

- Warm up the engine.

- Turn the ignition switch off.

- Connect the intelligent tester to the DLC3.

- Turn the ignition switch on (IG) and turn the tester ON.

- Enter the following menus: Powertrain / Engine and ECT / Active Test.

- Follow the instructions on the tester and read the Active Test.

Item

| Test Detail

| Diagnostic Note

|

Activate the Lock Up

| [Test Details]

Control shift solenoid DSL to set automatic transaxle to the lock-up condition

[Vehicle Condition]

- Throttle valve opening angle: Less than 35%

- Vehicle speed: 60 km/h (36 mph) or more

| Possible to check shift solenoid valve DSL operation

|

- HINT:

- This test can be conducted when the vehicle speed is 60 km/h (36 mph) or more.

- This test can be conducted in the 3rd or O/D gear.

- Lightly depress the accelerator pedal and check that the engine speed does not change abruptly.

- HINT:

- When changing the accelerator pedal opening angle while driving, if the engine speed does not change, lock-up is ON.

- Slowly release the accelerator pedal in order to decelerate. (Do not fully release the pedal as that will close the throttle valve and lock-up may be turned OFF.)

| 1.CHECK OTHER DTC OUTPUT (IN ADDITION TO DTC P0741) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch on (IG) and turn the tester ON.

Enter the following menus: Powertrain / Engine and ECT / DTC / Current or Pending.

Read the DTCs using the tester.

- Result:

Display (DTC output)

| Proceed to

|

Only P0741 is output

| A

|

P0741 and other DTCs are output

| B

|

- HINT:

- If any other codes besides P0741 are output, perform troubleshooting for those DTCs first.

| 2.INSPECT TRANSMISSION WIRE (SHIFT SOLENOID VALVE DSL) |

Disconnect the B29 wire connector.

Measure the resistance of the transmission wire.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

3 (DSL) - Body ground

| 20°C (68°F)

| 11 to 13 Ω

|

| 3.CHECK WIRE HARNESS (TRANSMISSION WIRE - ECM) |

Connect the B29 wire connector.

Disconnect the B32 ECM connector.

Measure the resistance of the wire harness side connector.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

B32-79 (DSL) - Body ground

| 20°C (68°F)

| 11 to 13 Ω

|

| | REPAIR OR REPLACE HARNESS AND CONNECTOR |

|

|

| 4.INSPECT SHIFT SOLENOID VALVE DSL |

Remove the shift solenoid valve DSL.

Measure the resistance of the solenoid valve.

- Standard resistance:

- 11 to 13 Ωat 20°C (68°F)

Connect the battery's positive (+) lead to the terminal of the solenoid valve connector, and the negative (-) lead to the solenoid body. Then check that the valve moves and makes an operating noise.

- OK:

- Valve moves and makes operating noise.

| | REPLACE SHIFT SOLENOID VALVE DSL |

|

|

| 5.CHECK TRANSMISSION WIRE |

- OK:

- The connectors and pins are securely installed.

There is no open or short on the wire harness.

| | REPAIR OR REPLACE TRANSMISSION WIRE |

|

|

| 6.INSPECT TRANSMISSION VALVE BODY ASSEMBLY |

Check the transmission valve body assembly.

- OK:

- There are no foreign objects on each valve.

| | REPAIR OR REPLACE TRANSMISSION VALVE BODY ASSEMBLY |

|

|

| 7.INSPECT TORQUE CONVERTER CLUTCH ASSEMBLY |

Check the torque converter clutch assembly (RAV4_ACA30 RM000001GS000VX.html).

- OK:

- The torque converter clutch operates normally.

| | REPLACE TORQUE CONVERTER CLUTCH ASSEMBLY |

|

|

| OK |

|

|

|

| REPAIR AUTOMATIC TRANSAXLE ASSEMBLY |

|