Dtc P0724 Brake Switch B Circuit High

Engine. Toyota Rav4. Aca30, 33, 38 Gsa33 Zsa30, 35

DESCRIPTION

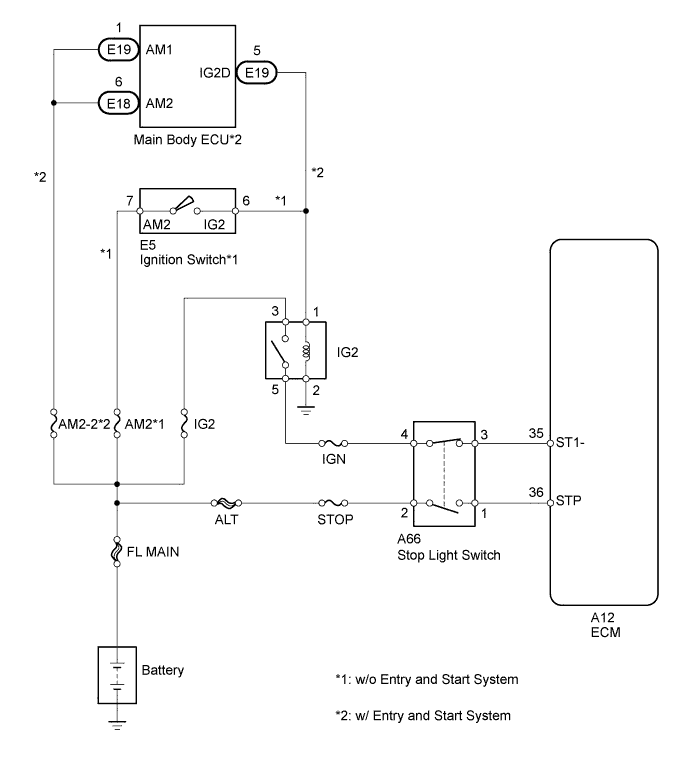

WIRING DIAGRAM

INSPECTION PROCEDURE

READ VALUE USING INTELLIGENT TESTER (STOP LIGHT SWITCH)

INSPECT STOP LIGHT SWITCH ASSEMBLY

CHECK HARNESS AND CONNECTOR (ECM - STOP LIGHT SWITCH ASSEMBLY)

DTC P0724 Brake Switch "B" Circuit High |

DESCRIPTION

This DTC indicates that the stop light switch remains on. When the stop light switch remains on during GO and STOP driving, the ECM interprets this as a fault in the stop light switch. Then the MIL illuminates and the ECM stores the DTC.DTC No.

| DTC Detection Condition

| Trouble Area

|

P0724

| The stop light switch remains on even when the vehicle is driven in a GO (30 km/h (18.63 mph) or more) and STOP (less than 3 km/h (1.86 mph)) pattern 5 times (2 trip detection logic).

| - Short in stop light switch signal circuit

- Stop light switch

- ECM

|

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- Inspect the fuses for circuits related to this system before performing the following inspection procedure.

- HINT:

- Using the intelligent tester's Data List allows switch, sensor, actuator and other item values to be read without removing any parts. Reading the Data List early in troubleshooting is one way to save time.

- Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, if the air fuel ratio was lean or rich, and other data from the time the malfunction occurred.

| 1.READ VALUE USING INTELLIGENT TESTER (STOP LIGHT SWITCH) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON.

Turn the tester on.

Enter the following menus: Powertrain / Engine and ECT / Data List / Stop Light Switch.

Read the value displayed on the tester when the brake pedal is depressed and released.

- OK:

Brake Pedal

| Display

|

Released

| OFF

|

Depressed

| ON

|

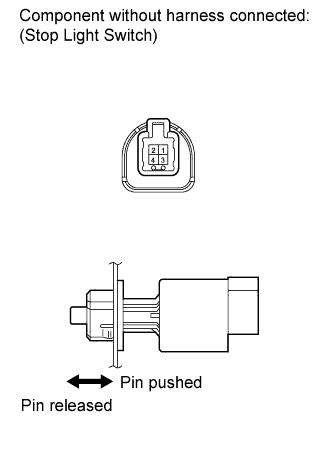

| 2.INSPECT STOP LIGHT SWITCH ASSEMBLY |

Disconnect the stop light switch assembly connector.

Remove the stop light switch assembly.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Switch Condition

| Specified Condition

|

1 - 2

| Switch pin released

| Below 1 Ω

|

Switch pin pushed

| 10 kΩ or higher

|

3 - 4

| Switch pin released

| 10 kΩ or higher

|

Switch pin pushed

| Below 1 Ω

|

Reinstall the stop light switch assembly.

Reconnect the stop light switch assembly connector.

| | REPLACE STOP LIGHT SWITCH ASSEMBLY |

|

|

| 3.CHECK HARNESS AND CONNECTOR (ECM - STOP LIGHT SWITCH ASSEMBLY) |

Disconnect the ECM connector.

Measure the voltage according to the value(s) in the table below.

- Standard Voltage:

Tester Connection

| Condition

| Specified Condition

|

A12-36 (STP) - Body ground

| Brake pedal depressed

| 11 to 14 V

|

A12-36 (STP) - Body ground

| Brake pedal released

| Below 1.5 V

|

Text in Illustration*1

| Front view of wire harness connector

(to ECM)

|

Reconnect the ECM connector.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR (ECM - STOP LIGHT SWITCH ASSEMBLY) |

|

|