Fuel Injector -- Inspection |

| 1. INSPECT FUEL INJECTOR ASSEMBLY |

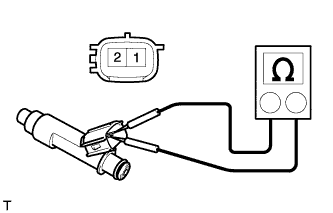

Measure the resistance between the injector terminals.

- Standard resistance:

- 11.6 to 12.4 Ω at 20°C (68°F)

|

Inspect the injector injection.

- CAUTION:

- Keep the injector away from sparks during the test.

Connect SST (fuel tube connector) to SST (hose), then connect them to the fuel pipe (vehicle side).

- SST

- 09268-31011(09268-41500,90467-13001,95336-08070)

Install the O-ring to the fuel injector.

Connect SST (adapter and hose) to the injector, and hold the injector and union with SST (clamp).

- SST

- 09268-31011(09268-41110,09268-41130,09268-41310)

Put the injector into the graduated cylinder.

- CAUTION:

- Install a suitable vinyl tube onto the injector to contain gasoline spray.

Operate the fuel pump.

Connect SST (wire) to the injector and the battery for 15 seconds, and measure the injection volume with the graduated cylinder. Test each injector 2 or 3 times.

- SST

- 09842-30080

- Standard injection volume:

- 76 to 92 cm3 (4.6 to 5.6 cu in.) per 15 seconds

- Standard difference between each injector:

- 16 cm3 (1.0 cu in.) or less

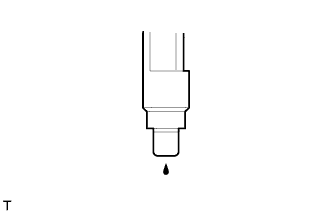

Inspect the fuel leakage.

Disconnect the SST (wire) tester probes from the battery and check the fuel leakage from the injector.

- Standard fuel drop:

- 1 drop or less per 12 minutes

Turn the ignition switch off.

Remove SST.

- SST

- 09842-30080

Disconnect the intelligent tester from the DLC3.

Reconnect the fuel inlet hose (rear fuel pipe) to the fuel main tube.

|