Dtc P0046 Turbocharger / Supercharger Boost Control Solenoid Circuit Range / Performance

DESCRIPTION

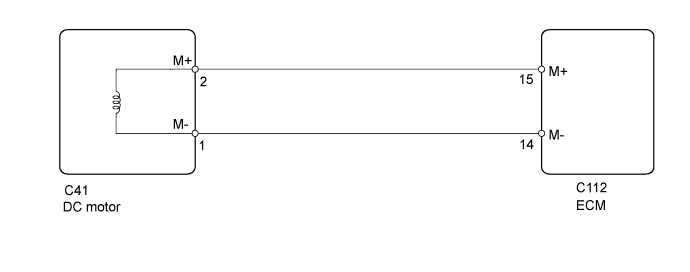

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK FOR ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0046, P0047 AND/OR P0048)

INSPECT TURBOCHARGER SUB-ASSEMBLY (DC MOTOR OPERATION)

INSPECT TURBOCHARGER SUB-ASSEMBLY (DC MOTOR RESISTANCE)

CHECK HARNESS AND CONNECTOR (DC MOTOR - ECM)

REPLACE ECM

REPLACE TURBOCHARGER SUB-ASSEMBLY

REPAIR OR REPLACE HARNESS OR CONNECTOR

CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED

DTC P0046 Turbocharger / Supercharger Boost Control Solenoid Circuit Range / Performance |

DTC P0047 Turbocharger/Supercharger Boost Control "A" Circuit Low |

DTC P0048 Turbocharger/Supercharger Boost Control "A" Circuit High |

DESCRIPTION

These DTCs indicate that the DC motor of the turbocharger is malfunctioning. The ECM monitors the DC motor current to detect an open or short in the DC motor circuit. If the current meets certain criteria, the ECM stores a DTC and illuminates the MIL immediately.The DC motor is used to operate the nozzle vane of the turbocharger. The nozzle vane opens and closes to change the velocity of exhaust emissions in order to control the turbo pressure. The ECM varies the duty ratio of the DC motor in accordance with the driving conditions.If the nozzle vane is stuck closed (DC motor stuck off), drivability may deteriorate at wide open throttle. If the nozzle vane is stuck open (DC motor stuck on), drivability may deteriorate at intermediate throttle positions or the engine power may be insufficient.P0046DTC Detection Drive Pattern

| DTC Detection Condition

| Trouble Area

|

Ignition switch ON for 5 seconds

| Either condition is met when the motor is operating (1 trip detection logic):

- The DC motor duty ratio exceeds the threshold for 0.5 seconds for the specified number of times (in terms of time, this amounts to 100 seconds or more).

- DC motor current is 2.2 A or higher for 5 seconds or more.

| - Open or short in DC motor (turbocharger sub-assembly) circuit

- DC motor (turbocharger sub-assembly)

- Turbocharger nozzle vane is stuck or movement is irregular

|

P0047DTC Detection Drive Pattern

| DTC Detection Condition

| Trouble Area

|

2 seconds after engine is started, race engine for 1 second

| The DC motor duty ratio is 80% or more and the motor current is 0.5 A or less for 3 seconds or more (1 trip detection logic).

| - Open in DC motor (turbocharger sub-assembly) circuit

- DC motor (turbocharger sub-assembly)

- Turbocharger nozzle vane is stuck or movement is irregular

|

P0048DTC Detection Drive Pattern

| DTC Detection Condition

| Trouble Area

|

2 seconds after engine is started, race engine for 1 second

| Overcurrent is detected 25 times or more (0.4 seconds or more) (1 trip detection logic).

| - Short in DC motor (turbocharger sub-assembly) circuit

- DC motor (turbocharger sub-assembly)

- Turbocharger nozzle vane is stuck or movement is irregular

|

- HINT:

- If DTC P0046, P0047 and/or P0048 is stored due to the nozzle vane being stuck closed, the following symptom may appear:

- Vehicle surge when driving with full load

- If DTC P0046, P0047 and/or P0048 is stored due to the nozzle vane being stuck open, the following symptoms may appear:

- Lack of power

- Vehicle surge or hesitation under light or medium load

WIRING DIAGRAM

INSPECTION PROCEDURE

- NOTICE:

- Inspect the fuses of circuits related to this system before performing the following inspection procedure.

- After replacing the ECM, the new ECM needs registration (HILUX_TGN26 RM0000012XK070X.html) and initialization (HILUX_TGN26 RM000000TIN057X.html).

- After replacing the fuel supply pump assembly, the ECM needs initialization (HILUX_TGN26 RM000000TIN057X.html).

- After replacing an injector assembly, the ECM needs registration (HILUX_TGN26 RM0000012XK070X.html).

- HINT:

- Read freeze frame data using the intelligent tester. Freeze frame data records the engine condition when malfunctions are detected. When troubleshooting, freeze frame data can help determine if the vehicle was moving or stationary, if the engine was warmed up or not, and other data from the time the malfunction occurred.

| 1.CHECK FOR ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0046, P0047 AND/OR P0048) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON and turn the tester on.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Read the DTCs.

ResultResult

| Proceed to

|

P0046, P0047 and/or P0048 is output

| A

|

P0046, P0047 and/or P0048 and other DTCs are output

| B

|

- HINT:

- If codes other than P0046, P0047 and/or P0048 are output, perform troubleshooting for those DTCs first.

| 2.INSPECT TURBOCHARGER SUB-ASSEMBLY (DC MOTOR OPERATION) |

Inspect the turbocharger sub-assembly (HILUX_TGN26 RM000001A3W031X_01_0010.html).

| OK |

|

|

|

| CHECK FOR INTERMITTENT PROBLEMS |

|

| 3.INSPECT TURBOCHARGER SUB-ASSEMBLY (DC MOTOR RESISTANCE) |

Disconnect the DC motor connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

1 (M-) - 2 (M+)

| Always

| 1 to 100 Ω

|

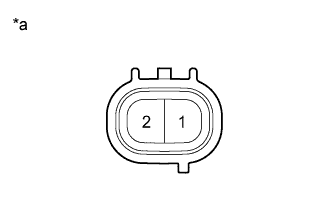

Text in Illustration*a

| Component without harness connected

(DC Motor)

|

Reconnect the DC motor connector.

| 4.CHECK HARNESS AND CONNECTOR (DC MOTOR - ECM) |

Disconnect the DC motor connector.

Disconnect the ECM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

C41-1 (M-) - C112-14 (M-)

| Always

| Below 1 Ω

|

C41-2 (M+) - C112-15 (M+)

| Always

| Below 1 Ω

|

C41-1 (M-) or C112-14 (M-) - Body ground

| Always

| 10 kΩ or higher

|

C41-2 (M+) or C112-15 (M+) - Body ground

| Always

| 10 kΩ or higher

|

Reconnect the DC motor connector.

Reconnect the ECM connector.

Replace the ECM (HILUX_TGN26 RM0000013Z001HX.html).

| 6.REPLACE TURBOCHARGER SUB-ASSEMBLY |

Replace the turbocharger sub-assembly (HILUX_TGN26 RM000002S6F00OX.html).

| 7.REPAIR OR REPLACE HARNESS OR CONNECTOR |

Repair or replace the harness or connector.

| 8.CONFIRM WHETHER MALFUNCTION HAS BEEN SUCCESSFULLY REPAIRED |

Connect the intelligent tester to the DLC3.

Clear the DTCs (HILUX_TGN26 RM000000PDK11ZX.html).

Turn the ignition switch off.

Turn the ignition switch to ON for 5 seconds or more.

Enter the following menus: Powertrain / Engine and ECT / DTC.

Confirm that the DTC is not output again.