Dtc P0818 Driveline Disconnect Switch Input Circuit

Drivetrain. Hilux. Tgn26, 36 Kun25, 26, 35, 36 Ggn25

DESCRIPTION

MONITOR DESCRIPTION

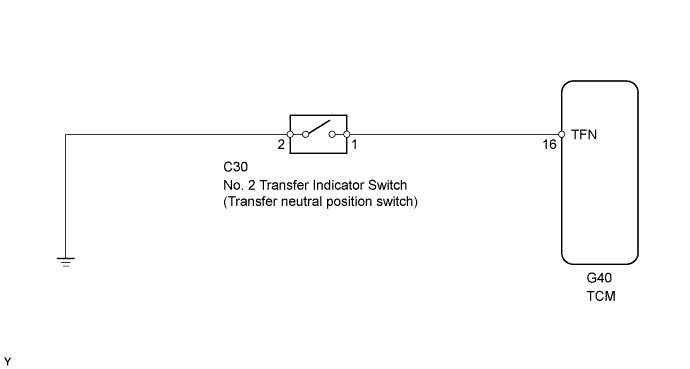

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK HARNESS AND CONNECTOR (NO. 2 TRANSFER INDICATOR SWITCH - BODY GROUND)

INSPECT NO. 2 TRANSFER INDICATOR SWITCH

CHECK HARNESS AND CONNECTOR (NO. 2 TRANSFER INDICATOR SWITCH - TCM)

DTC P0818 Driveline Disconnect Switch Input Circuit |

DESCRIPTION

The TCM detects the signal from the No. 2 transfer indicator switch (the transfer neutral position switch).This DTC indicates that the No. 2 transfer indicator switch remains on.DTC No.

| DTC Detection Conditions

| Trouble Area

|

P0818

| The No. 2 transfer indicator switch remains on while the vehicle is running under the following conditions for 30 seconds. (2-trip detection logic):

- Vehicle speed is 25.1 km/h (15.6 mph) or more.

- Transfer high and low shift lever position: H.

| - Short in No. 2 transfer indicator switch (the transfer neutral position switch) circuit

- No. 2 transfer indicator switch

- TCM

|

MONITOR DESCRIPTION

The TCM detects whether or not the transfer high and low shift lever is in neutral by monitoring the signal from the No. 2 transfer indicator switch.If the TCM detects that the transfer high and low shift lever is in neutral under the following conditions, the TCM will conclude that there is a malfunction of the No. 2 transfer indicator switch:- No. 2 transfer indicator switch indicates that the transfer high and low shift lever is in neutral.

- Transfer high and low shift lever is in the H position.

- The vehicle is traveling at 25.1 km/h (15.6 mph) or more.

- The No. 2 transfer indicator switch has been on for more than 30 seconds.

If all of the above conditions are detected, the TCM will conclude that there is a malfunction of the No. 2 transfer indicator switch, illuminate the MIL and store the DTC.

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.CHECK HARNESS AND CONNECTOR (NO. 2 TRANSFER INDICATOR SWITCH - BODY GROUND) |

Disconnect the No. 2 transfer indicator switch connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

C30-2 - Body ground

| Always

| Below 1 Ω

|

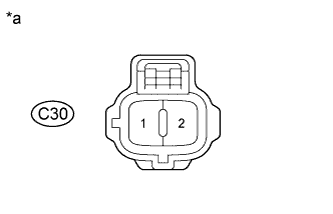

Text in Illustration*a

| Front view of wire harness connector

(to No. 2 Transfer Indicator Switch)

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 2.INSPECT NO. 2 TRANSFER INDICATOR SWITCH |

Remove the No. 2 transfer indicator switch.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Switch Condition

| Specified Condition

|

1 - 2

| Not pushed

| 10 kΩ or higher

|

1 - 2

| Pushed

| Below 1 Ω

|

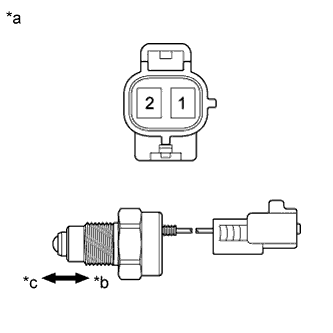

Text in Illustration*a

| Component without harness connected

(No. 2 Transfer Indicator Switch)

|

*b

| Pushed

|

*c

| Not pushed

|

| 3.CHECK HARNESS AND CONNECTOR (NO. 2 TRANSFER INDICATOR SWITCH - TCM) |

Disconnect the C30 No. 2 transfer indicator switch connector.

Disconnect the G40 TCM connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

C30-1 - G40-16 (TFN)

| Always

| Below 1 Ω

|

C30-1 or G40-16 (TFN) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|