Meter / Gauge System Speedometer Malfunction

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK SPEEDOMETER SENSOR (OUTPUT SIGNAL)

CHECK HARNESS AND CONNECTOR (SPEEDOMETER SENSOR - COMBINATION METER ASSEMBLY AND BODY GROUND)

METER / GAUGE SYSTEM - Speedometer Malfunction |

DESCRIPTION

The combination meter receives vehicle speed signals from the speedometer sensor via the direct line.

WIRING DIAGRAM

INSPECTION PROCEDURE

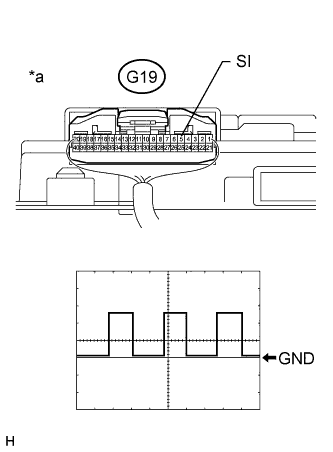

| 1.CHECK SPEEDOMETER SENSOR (OUTPUT SIGNAL) |

Remove the combination meter assembly with the connector(s) still connected.

Using an oscilloscope, check the signal waveform of the meter.

Measurement ConditionItem

| Content

|

Tester Connection

| G19-5 (SI) - Body ground

|

Tool Setting

| 5 V/DIV., 20 msec./DIV.

|

Condition

| Driving at approx. 20 km/h (12 mph)

|

- HINT:

- As the vehicle speed increases, the wavelength shortens.

- OK:

- The waveform displayed is as shown in the illustration.

Text in Illustration*a

| Component with harness connected

(Combination Meter Assembly)

|

| 2.CHECK HARNESS AND CONNECTOR (SPEEDOMETER SENSOR - COMBINATION METER ASSEMBLY AND BODY GROUND) |

Disconnect the C38 speedometer sensor connector.

Disconnect the G19 combination meter assembly connector.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

G19-5 (SI) - C38-3 (SI)

| Always

| Below 1 Ω

|

G19-31 (MS5) - C38-1 (IG+)

| Always

| Below 1 Ω

|

C38-1 (IG+) - C38-2 (SE)

| Always

| 10 kΩ or higher

|

C38-1 (IG+) - C38-3 (SI)

| Always

| 10 kΩ or higher

|

C38-2 (SE) - C38-3 (SI)

| Always

| 10 kΩ or higher

|

C38-2 (SE) - Body ground

| Always

| Below 1 Ω

|

ResultResult

| Proceed to

|

NG

| A

|

OK (for VF2A)

| B

|

OK (for A343E)

| C

|

OK (for R150, R151)

| D

|

| |

|

| | REPLACE SPEEDOMETER SENSOR |

|

|

| |

|

| A |

|

|

|

| REPAIR OR REPLACE HARNESS OR CONNECTOR |

|