Drivetrain. Hilux. Tgn26, 36 Kun25, 26, 35, 36 Ggn25

A340F Automatic Transmission Transaxle. Hilux. Tgn26, 36 Kun25, 26, 35, 36 Ggn25

Torque Converter And Drive Plate -- Inspection |

| 1. INSPECT TORQUE CONVERTER CLUTCH ASSEMBLY |

|

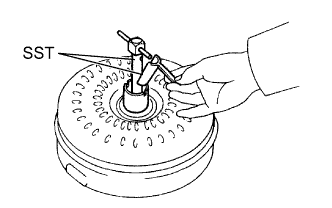

Inspect the one-way clutch.

Set SST into the inner race of the one-way clutch.

- SST

- 09350-32014(09351-32010)

Install SST so that it fits in the notch of the torque converter hub and in the outer race of the one-way clutch.

- SST

- 09350-32014(09351-32020)

Stand the torque converter up and turn SST.

- OK:

- The one-way clutch rotates smoothly when turned clockwise and locks when turned counterclockwise.

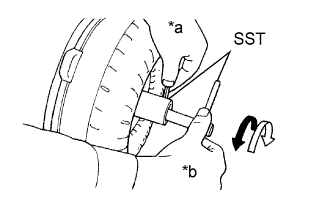

Text in Illustration *a Hold *b Turn

Lock

Smooth

Inspect the torque converter assembly.

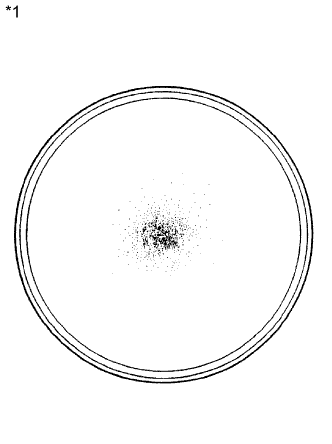

If any of the following problems are present, replace the torque converter assembly.Text in Illustration *1 Sample showing maximum allowable amount of powder in ATF - A metallic sound is emitted from the torque converter assembly during the stall test or when the shift lever is moved to N.

- The one-way clutch turns smoothly or is locked in both directions.

- The amount of powder in the ATF is more than the sample shown in the illustration (refer to the sample).

- HINT:

- The sample illustration shows approximately 0.025 liters (0.026 US qts, 0.022 Imp. qts) of ATF that was removed from a torque converter.

- A metallic sound is emitted from the torque converter assembly during the stall test or when the shift lever is moved to N.

|

Replace the ATF in the torque converter.

- HINT:

- If the ATF is discolored or has a foul odor, stir the ATF in the torque converter before replacing the ATF.

Clean and check the oil cooler and oil pipe line.

- HINT:

- If the torque converter is inspected or the ATF is replaced, it is necessary to clean the oil cooler and oil pipe line.

- Apply compressed air of 196 kPa (2.0 kgf/cm2, 28 psi) into the inlet hose.

- If a large amount of powder is found in the ATF, add new ATF using a bucket pump and clean the oil cooler and oil pipe line again.

- If the ATF is cloudy, inspect the oil cooler.

Prevent deformation of the torque converter and damage to the oil pump gear.

- NOTICE:

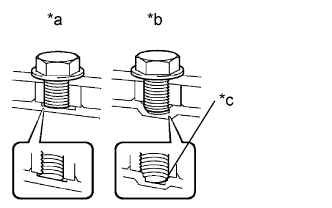

- Make sure that all of the bolts are the same length and that the specified bolts are used.

Text in Illustration *a CORRECT *b INCORRECT *c Bottom is damage - HINT:

- If there is any damage to the tip of a bolt for the torque converter or to the bottom of a bolt hole, replace the bolt and torque converter.

|

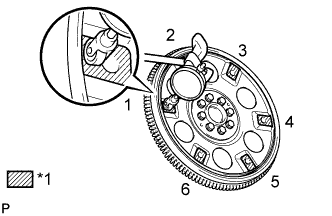

| 2. INSPECT DRIVE PLATE AND RING GEAR |

|

Check the drive plate for damage.

Set up a dial indicator and measure the runout at the 6 areas on the drive plate surface that contact the torque converter.

Text in Illustration *1 Measurement Point - Maximum runout:

- 0.30 mm (0.0118 in.)

- HINT:

- If the runout is more than the maximum or the drive plate is damage, replace the drive plate (HILUX_TGN26 RM00000147M02AX_01_0134.html).