Oil Pump -- Inspection |

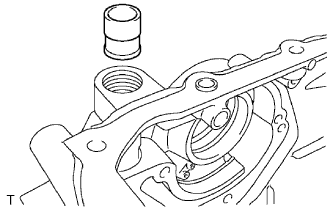

| 1. INSPECT OIL PUMP RELIEF VALVE |

Coat the relief valve with engine oil and drop it into the relief valve hole. Check that the oil pump relief valve falls in smoothly by its own weight.

If the valve does not fall smoothly, replace the oil pump relief valve. If necessary, replace the timing chain cover sub-assembly.

|

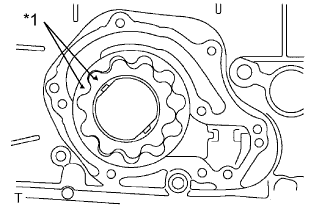

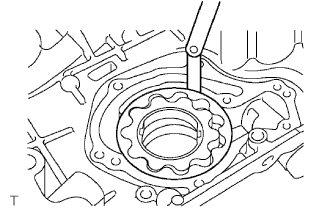

| 2. INSPECT OIL PUMP ROTOR SET |

Install the rotors to the oil pump body with the marks facing outward. Check that the rotors revolve smoothly.

Text in Illustration *1 Alignment Mark

|

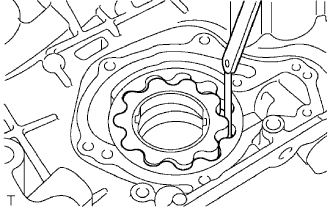

Check the tip clearance.

Using a feeler gauge, measure the clearance between the drive and driven rotor tips as shown in the illustration.

- Standard tip clearance:

- 0.040 to 0.160 mm (0.00157 to 0.00630 in.)

- Maximum tip clearance:

- 0.260 mm (0.0102 in.)

|

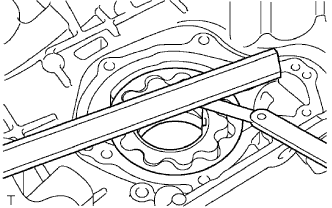

Check the side clearance.

Using a feeler gauge and precision straightedge, measure the clearance between the rotors and precision straightedge as shown in the illustration.

- Standard side clearance:

- 0.025 to 0.075 mm (0.000984 to 0.00295 in.)

- Maximum side clearance:

- 0.130 mm (0.00512 in.)

|

Check the body clearance.

Using a feeler gauge, measure the clearance between the oil pump body and driven rotor as shown in the illustration.

- Standard body clearance:

- 0.025 to 0.325 mm (0.000984 to 0.0128 in.)

- Maximum body clearance:

- 0.425 mm (0.0167 in.)

|