Drivetrain. Hilux. Tgn26, 36 Kun25, 26, 35, 36 Ggn25

DESCRIPTION

MONITOR DESCRIPTION

INSPECTION PROCEDURE

CHECK DTC OUTPUT (IN ADDITION TO DTCS P0894 AND P2714)

PERFORM ACTIVE TEST USING INTELLIGENT TESTER (SHIFT SOLENOID VALVE SLT)

PERFORM ACTIVE TEST USING INTELLIGENT TESTER (RUNNING TEST)

INSPECT SHIFT SOLENOID VALVE S1

INSPECT TRANSMISSION VALVE BODY ASSEMBLY

INSPECT TORQUE CONVERTER ASSEMBLY

INSPECT SHIFT SOLENOID VALVE S2

INSPECT TRANSMISSION VALVE BODY ASSEMBLY

INSPECT TORQUE CONVERTER ASSEMBLY

INSPECT SHIFT SOLENOID VALVE SL2

INSPECT TRANSMISSION VALVE BODY ASSEMBLY

INSPECT TORQUE CONVERTER ASSEMBLY

INSPECT SHIFT SOLENOID VALVE SL1

INSPECT SHIFT SOLENOID VALVE SR

INSPECT TRANSMISSION VALVE BODY ASSEMBLY

INSPECT TORQUE CONVERTER ASSEMBLY

INSPECT SHIFT SOLENOID VALVE SLT

INSPECT TRANSMISSION VALVE BODY ASSEMBLY

INSPECT TORQUE CONVERTER ASSEMBLY

DTC P0894 Transmission Component Slipping |

DTC P2714 Pressure Control Solenoid "D" Performance (Shift Solenoid Valve SLT) |

DESCRIPTION

Refer to DTC P2716 (HILUX_TGN26 RM000000W8A0I6X_01.html).DTC Code

| DTC Detection Condition

| Trouble Area

|

P0894

| The TCM detects a malfunction of the SLT, S1, S2, SR, SL1, SL2 or 1-2 shift solenoid valves according to the revolution difference of the turbine and output shaft, and also by the oil pressure (2 trip detection logic).

| - Shift solenoid valve SLT remains open or closed

- Shift solenoid valve S1, S2, SR, SL1 or SL2 remains open or closed

- 1-2 shift valve is stuck

- Valve body is blocked

- Automatic transmission (clutch, brake or gear, etc.)

|

P2714

| The TCM detects a malfunction of the SLT shift solenoid valve (ON side) according to the revolution difference of the turbine and output shaft, and also by the oil pressure (2 trip detection logic).

| - Shift solenoid valve SLT remains open or closed

- Shift solenoid valve S1, S2, SR, SL1 or SL2 remains open or closed

- 1-2 shift valve is stuck

- Valve body is blocked

- Automatic transmission (clutch, brake or gear, etc.)

|

MONITOR DESCRIPTION

The TCM calculates the amount of heat absorbed by the friction material based on the difference in revolution (clutch slippage) between the turbine and output shaft. The TCM turns on the MIL and stores this DTC when the amount of heat absorption exceeds the specified value.There are two reasons that make the revolution different.- When the shift solenoid valve SLT remains on, oil pressure goes down and clutch engagement force decreases.

- When the shift solenoid valve remains on or off, the gear position commanded by the TCM and the actual gear position are not the same.

- NOTICE:

- If you continue driving under these conditions, the clutch will burn out and the vehicle will no longer be drivable.

INSPECTION PROCEDURE

| 1.CHECK DTC OUTPUT (IN ADDITION TO DTCS P0894 AND P2714) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to ON.

Turn the intelligent tester on.

Enter the following menus: Powertrain / ECT / Trouble Codes.

Read the DTCs using the tester.

ResultResult

| Proceed to

|

P0894 and/or P2714 is output

| A

|

P0894, P2714 and other DTCs are output

| B

|

- HINT:

- If any other codes besides P0894 and P2714 are output, perform troubleshooting for those DTCs first.

| 2.PERFORM ACTIVE TEST USING INTELLIGENT TESTER (SHIFT SOLENOID VALVE SLT) |

- NOTICE:

- Perform the test while the ATF temperature is between 50 and 80°C (122 and 176°F).

- Be careful to prevent the hose of SST from interfering with the exhaust pipe.

- Perform the test with the A/C off.

- HINT:

- Using the intelligent tester to perform Active Tests allows relays, VSVs, actuators and other items to be operated without removing any parts. This non-intrusive functional inspection can be very useful because intermittent operation may be discovered before parts or wiring is disturbed. Performing Active Tests early in troubleshooting is one way to save diagnostic time. Data List information can be displayed while performing Active Tests.

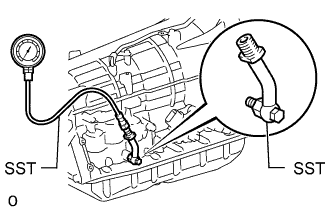

Remove the test plug from the transmission case and connect SST.

- SST

- 09992-00095(09992-00231,09992-00271)

Connect the intelligent tester to the DLC3.

Start the engine and warm it up.

Measure the line pressure with SST.

Turn the intelligent tester on.

Enter the following menus: Powertrain / ECT / Active Test.

According to the display on the tester, perform the Active Test.

Measure the line pressure.

ECTTester Display

| Test Part

| Control Range

| Diagnostic Note

|

Activate the Solenoid (SLT)*

| Operate shift solenoid valve SLT and raise line pressure

| ON or OFF

- HINT:

- OFF: Line pressure up (when Active Test "Activate the Solenoid (SLT)" is performed, TCM commands shift solenoid valve SLT to turn OFF)

- ON: No action (normal operation)

| [Vehicle Condition]

- Vehicle stopped

- Engine idling

|

- HINT:

- *: Activate the Solenoid (SLT) in the Active Test is performed to check the line pressure changes by connecting SST to the automatic transmission, which is used in the Hydraulic Test (HILUX_TGN26 RM000000W7B0P2X.html) as well. Note that the pressure values in the Active Test and hydraulic test are different.

- OK:

- The line pressure changes as specified when performing the Active Test.

| 3.PERFORM ACTIVE TEST USING INTELLIGENT TESTER (RUNNING TEST) |

- CAUTION:

- This test should always be performed with at least 2 people.

- NOTICE:

- Perform the test at the normal operating ATF temperature: 50 to 80°C (122 to 176°F).

- Perform the test with the A/C turned off.

- HINT:

- Using the intelligent tester to perform Active Tests allows relays, VSVs, actuators and other items to be operated without removing any parts. This non-intrusive functional inspection can be very useful because intermittent operation may be discovered before parts or wiring is disturbed. Performing Active Tests early in troubleshooting is one way to save diagnostic time. Data List information can be displayed while performing Active Tests.

Connect the intelligent tester to the DLC3.

Clear the DTC (HILUX_TGN26 RM000000W770U5X.html).

Warm up the engine.

Enter the following menus: Powertrain / ECT / Active Test.

According to the display on the tester, perform the Active Test.

- HINT:

- While driving, the shift position can be forcibly changed with the intelligent tester.

ECTTester Display

| Test Part

| Control Range

| Diagnostic Note

|

Control the Shift Position

| Operate shift solenoid valve and set each shift position

| - Press "→" button: Shift up

- Press "←" button: Shift down

| It is possible to check the operation of the shift solenoid valves.

[Vehicle Condition]

The vehicle speed is 50 km/h (31 mph) or less.

|

- HINT:

- This test can be conducted when the vehicle speed is 50 km/h (31 mph) or less.

- The 4th to 5th up-shift must be performed with the accelerator pedal released.

- The 5th to 4th down-shift must be performed with the accelerator pedal released.

- Do not operate the accelerator pedal for at least 2 seconds after shifting and do not shift successively.

- The shift position commanded by the TCM is shown in the Data List display on the tester.

Compare the TCM gear shift command and the actual gear position.

- OK:

- Gear position changes in accordance with the tester command.

ResultSystem Condition

| TCM Gear Shift Command

| Proceed to

|

1st

| 2nd

| 3rd

| 4th

| 5th

|

Malfunction

| Shift solenoid valve S1

| Stuck ON

| 1st

| 2nd

| 2nd

| 1st

| N*1

| A

|

Stuck OFF

| 4th

| 3rd

| 3rd

| 4th

| 5th

|

Shift solenoid valve S2

| Stuck ON*2

| 2nd

| 2nd

| 3rd

| 3rd

| N*1

| B

|

Stuck OFF*3

| 1st

| 1st

| 4th

| 4th

| 5th

|

Shift solenoid valve SL2

| Stuck ON

| 1st

| 2nd

| 3rd

| 4th

| N*1

| C

|

Stuck OFF

| 1st

| 2nd

| 3rd

| 4th

| 5th

|

Shift solenoid valve SR

| Stuck ON*4

| 1st

| 2nd

| 3rd

| 4th

| 5th

| D

|

Stuck OFF*5

| 1st

| 2nd

| 3rd

| 4th

| 4th

|

Normal

| 1st

| 2nd

| 3rd

| 4th

| 5th

| E

|

- HINT:

- *1: Neutral

- *2: When shift solenoid valve S2 is stuck ON, the vehicle cannot drive in reverse.

- *3: When shift solenoid valve S2 is stuck OFF, the 4th to 5th up-shift will have a large shift shock. Also, the 5th to 4th down-shift will have time lag.

- *4: When shift solenoid valve SR is stuck ON, the condition can be determined by checking if shift shock has increased excessively.

- *5: When shift solenoid valve SR is stuck OFF, moving the shift lever from N to D will cause a large shift shock.

- Gear shift can be determined by paying attention to changes in engine speed.

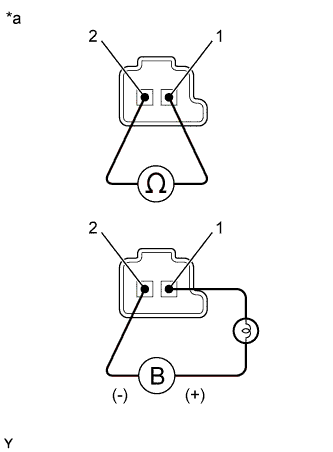

| 4.INSPECT SHIFT SOLENOID VALVE S1 |

Remove shift solenoid valve S1.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

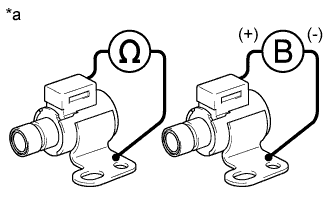

Shift solenoid valve S1 connector terminal - Shift solenoid valve S1 body

| 20°C (68°F)

| 11 to 15 Ω

|

Apply 12 V battery voltage to the shift solenoid valve and check that the valve moves and makes an operating noise.

- OK:

Measurement Condition

| Specified Condition

|

- Battery positive (+) → Shift solenoid valve S1 connector

- Battery negative (-) → Shift solenoid valve S1 body

| Valve moves and makes an operating noise

|

Text in Illustration*a

| Component without harness connected

(Shift Solenoid Valve S1)

|

| 5.INSPECT TRANSMISSION VALVE BODY ASSEMBLY |

Check the transmission valve body assembly (HILUX_TGN26 RM0000013FG02KX.html).

- OK:

- There are no foreign objects on any valve.

| 6.INSPECT TORQUE CONVERTER ASSEMBLY |

Check the torque converter assembly (HILUX_TGN26 RM0000013F203XX.html).

- OK:

- The torque converter assembly operates normally.

| 7.INSPECT SHIFT SOLENOID VALVE S2 |

Remove shift solenoid valve S2.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

Shift solenoid valve S2 connector terminal - Shift solenoid valve S2 body

| 20°C (68°F)

| 11 to 15 Ω

|

Apply 12 V battery voltage to the shift solenoid valve and check that the valve moves and makes an operating noise.

- OK:

Measurement Condition

| Specified Condition

|

- Battery positive (+) → Shift solenoid valve S2 connector

- Battery negative (-) → Shift solenoid valve S2 body

| Valve moves and makes an operating noise

|

Text in Illustration*a

| Component without harness connected

(Shift Solenoid Valve S2)

|

| 8.INSPECT TRANSMISSION VALVE BODY ASSEMBLY |

Check the transmission valve body assembly (HILUX_TGN26 RM0000013FG02KX.html).

- OK:

- There are no foreign objects on any valve.

| 9.INSPECT TORQUE CONVERTER ASSEMBLY |

Check the torque converter assembly (HILUX_TGN26 RM0000013F203XX.html).

- OK:

- The torque converter assembly operates normally.

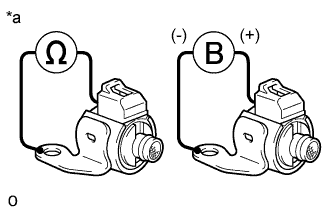

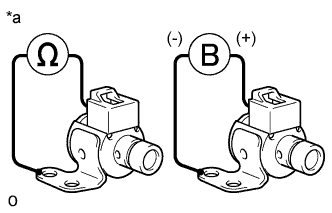

| 10.INSPECT SHIFT SOLENOID VALVE SL2 |

Remove shift solenoid valve SL2.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

1 - 2

| 20°C (68°F)

| 5.0 to 5.6 Ω

|

Apply 12 V battery voltage to the shift solenoid valve and check that the valve moves and makes an operating noise.

- OK:

Measurement Condition

| Specified Condition

|

- Battery positive (+) with a 21 W bulb → Terminal 1

- Battery negative (-) → Terminal 2

| Valve moves and makes an operating noise

|

Text in Illustration*a

| Component without harness connected

(Shift Solenoid Valve SL2)

|

| 11.INSPECT TRANSMISSION VALVE BODY ASSEMBLY |

Check the transmission valve body assembly (HILUX_TGN26 RM0000013FG02KX.html).

- OK:

- There are no foreign objects on any valve.

| 12.INSPECT TORQUE CONVERTER ASSEMBLY |

Check the torque converter assembly (HILUX_TGN26 RM0000013F203XX.html).

- OK:

- The torque converter assembly operates normally.

| 13.INSPECT SHIFT SOLENOID VALVE SL1 |

Remove shift solenoid valve SL1.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

1 - 2

| 20°C (68°F)

| 5.0 to 5.6 Ω

|

Apply 12 V battery voltage to the shift solenoid valve and check that the valve moves and makes an operating noise.

- OK:

Measurement Condition

| Specified Condition

|

- Battery positive (+) with a 21 W bulb → Terminal 1

- Battery negative (-) → Terminal 2

| Valve moves and makes an operating noise

|

Text in Illustration*a

| Component without harness connected

(Shift Solenoid Valve SL1)

|

| 14.INSPECT SHIFT SOLENOID VALVE SR |

Remove shift solenoid valve SR.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

Shift solenoid valve SR connector terminal - Shift solenoid valve SR body

| 20°C (68°F)

| 11 to 15 Ω

|

Apply 12 V battery voltage to the shift solenoid valve and check that the valve moves and makes an operating noise.

- OK:

Measurement Condition

| Specified Condition

|

- Battery positive (+) → Shift solenoid valve SR connector

- Battery negative (-) → Shift solenoid valve SR body

| Valve moves and makes an operating noise

|

Text in Illustration*a

| Component without harness connected

(Shift Solenoid Valve SR)

|

| 15.INSPECT TRANSMISSION VALVE BODY ASSEMBLY |

Check the transmission valve body assembly (HILUX_TGN26 RM0000013FG02KX.html).

- OK:

- There are no foreign objects on any valve.

| 16.INSPECT TORQUE CONVERTER ASSEMBLY |

Check the torque converter assembly (HILUX_TGN26 RM0000013F203XX.html).

- OK:

- The torque converter assembly operates normally.

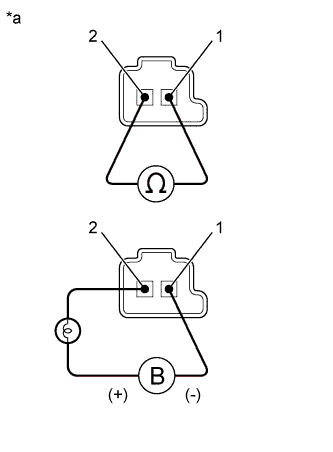

| 17.INSPECT SHIFT SOLENOID VALVE SLT |

Remove shift solenoid valve SLT.

Measure the resistance according to the value(s) in the table below.

- Standard Resistance:

Tester Connection

| Condition

| Specified Condition

|

1 - 2

| 20°C (68°F)

| 5.0 to 5.6 Ω

|

Apply 12 V battery voltage to the shift solenoid valve and check that the valve moves and makes an operating noise.

- OK:

Measurement Condition

| Specified Condition

|

- Battery positive (+) with a 21 W bulb → Terminal 2

- Battery negative (-) → Terminal 1

| Valve moves and makes an operating noise

|

Text in Illustration*a

| Component without harness connected

(Shift Solenoid Valve SLT)

|

| 18.INSPECT TRANSMISSION VALVE BODY ASSEMBLY |

Check the transmission valve body assembly (HILUX_TGN26 RM0000013FG02KX.html).

- OK:

- There are no foreign objects on any valve.

| 19.INSPECT TORQUE CONVERTER ASSEMBLY |

Check the torque converter assembly (HILUX_TGN26 RM0000013F203XX.html).

- OK:

- The torque converter assembly operates normally.