Fuel Pump -- Installation |

| 1. INSTALL FUEL SUCTION TUBE ASSEMBLY WITH PUMP AND GAUGE |

Install a new gasket onto the fuel tank.

|

Set the fuel suction tube assembly with pump and gauge to the fuel tank.

- NOTICE:

- Make sure that the fuel sender gauge arm does not bend.

|

| 2. INSTALL FUEL PUMP GAUGE RETAINER |

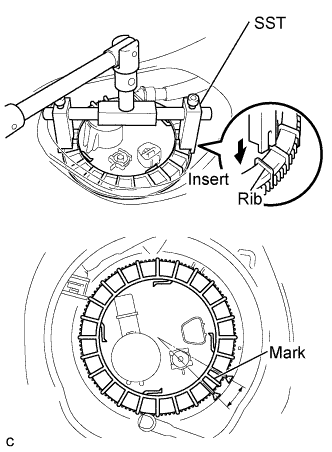

Align the protrusion of the fuel suction tube with the notch of the fuel tank.

While holding the fuel suction tube assembly by hand to prevent it from tilting, align the starting marks on the fuel pump gauge retainer and fuel tank and tighten the fuel pump gauge retainer.

|

Using SST and your hand, tighten the fuel pump gauge retainer 2 revolutions so that the mark of the retainer comes within the range shown in the illustration.

- SST

- 09808-14020(09808-01410,09808-01420,09808-01430)

- NOTICE:

- Use SST. Do not use any other tools such as a screwdriver.

- HINT:

- Insert the notch of SST into the rib of the fuel pump gauge retainer.

|

| 3. CONNECT FUEL TANK VENT HOSE |

Connect the fuel tank vent hose.

Align the fuel tank vent connector with the pipe, then push in the fuel tank vent connector until the retainer makes a "click" sound to connect the fuel tank vent hose to the fuel suction plate.

- NOTICE:

- Check that there are no scratches or foreign objects around the connecting surfaces of the fuel tank vent connector and pipe before performing this work.

- After connecting the fuel tank vent hose, check that the fuel tank vent hose is securely connected by pulling on the quick connector.

|

| 4. CONNECT FUEL TANK MAIN TUBE SUB-ASSEMBLY |

Connect the fuel tank main tube.

Push the fuel tube joint in the plug of the fuel suction plate, then install the tube joint clip.

- NOTICE:

- Check that there are no scratches or foreign objects around the connecting surfaces of the fuel tube joint and plug before performing this work.

- Check that the fuel tube joint is securely inserted to the end.

- Check that the tube joint clip is on the collar of the fuel tube joint.

- After installing the tube joint clip, check that the fuel tank main tube cannot be pulled out.

|

| 5. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL |

Connect the cable to the negative battery terminal.

- Torque:

- 5.4 N*m{55 kgf*cm, 48 in.*lbf}

| 6. INSPECT FOR FUEL LEAK |

Check fuel pump operation.

Connect the Techstream to the DLC3.

Turn the ignition switch ON and turn the Techstream on.

- NOTICE:

- Do not start the engine.

Enter the following menus: Powertrain / Engine and ECT / Active Test / Control the Fuel Pump / Speed.

Check for pressure in the fuel inlet tube from the fuel line. Check that sounds of fuel flowing from the fuel tank can be heard. If no sounds can be heard, check the integration relay, fuel pump, ECM and wiring connectors.

Inspect for fuel leaks.

Check that there are no fuel leakage after performing maintenance anywhere on the fuel system. If there is a fuel leak, repair or replace parts as necessary.

Turn the ignition switch off.

Disconnect the Techstream from the DLC3.

| 7. INSTALL REAR FLOOR SERVICE HOLE COVER |

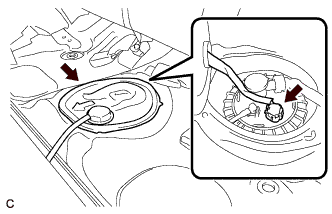

Connect the fuel pump connector.

|

Install the rear floor service hole cover.

| 8. INSTALL REAR SEAT CUSHION ASSEMBLY |

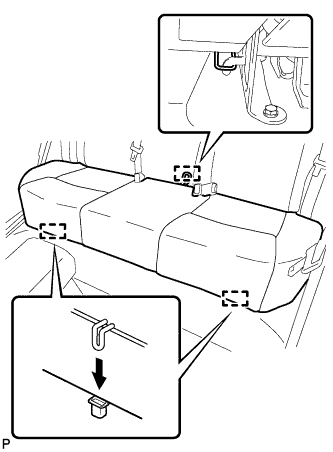

Attach the rear hook of the seat cushion to the seatback.

|

Attach the 2 front hooks of the seat cushion to the vehicle body.

Confirm that the seat cushion is firmly installed.

- NOTICE:

- When installing the seat cushion, make sure that the seat belt buckle is not under the seat cushion.