Front Wheel Alignment -- Adjustment |

- NOTICE:

- For vehicles equipped with VSC, if the wheel alignment has been adjusted, and if suspension or underbody components have been removed/installed or replaced, be sure to perform the following initialization procedure in order for the system to function normally:

- Disconnect the cable from the negative (-) battery terminal for more than 2 seconds.

- Reconnect the cable to the negative (-) battery terminal.

- Perform zero point calibration of the yaw rate and acceleration sensor and test mode inspection.

| 1. INSPECT TIRES |

Check the tires for wear and proper inflation pressure.

Cold Tire Inflation Pressure Tire Size Front

kPa (kgf/cm2, psi)Rear

kPa (kgf/cm2, psi)P195/65R15 89S 210 (2.1, 30) 210 (2.1, 30) P205/55R16 89H

P215/45R17 87W

205/55R16 91V220 (2.2, 32) 220 (2.2, 32)

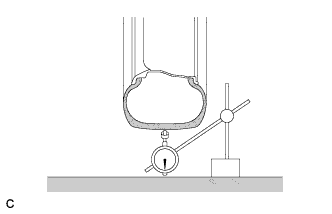

Using a dial indicator, check the runout of the tires.

- Maximum tire runout:

- 1.4 mm (0.0551 in.)

|

| 2. MEASURE VEHICLE HEIGHT |

|

- NOTICE:

- Before inspecting the wheel alignment, adjust the vehicle height to the specified value.

- Be sure to perform measurement on a level surface.

- If it is necessary to go under the vehicle for measurement, confirm that the parking brake is applied and the vehicle is secured with chocks.

Bounce the vehicle up and down at the corners several times to stabilize the suspension.

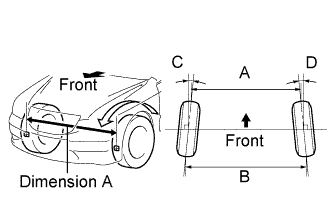

Measure the vehicle height.

- Measuring points:

- A:

- No. 1 lower suspension arm bushing set bolt ground clearance

- B:

- Rear axle beam set bolt ground clearance

- C:

- Front wheel center ground clearance

- D:

- Rear wheel center ground clearance

- Vehicle Height (Unloaded Vehicle):

- Engine Tire Size Front C - A Rear D - B for TMC Made 2ZR-FE - 92 mm (3.62 in.) 45 mm (1.77 in.) except TMC Made 2ZR-FE 195/65R15 92 mm (3.62 in.)

80 mm (3.15 in.)*45 mm (1.77 in.)

32 mm (1.26 in.)*205/55R16 215/45R17 96 mm (3.78 in.) 51 mm (2.01 in.) 2AZ-FE - 96 mm (3.78 in.)

81 mm (3.19 in.)*51 mm (2.01 in.)

36 mm (1.42 in.)*

| 3. INSPECT WHEEL ANGLE |

|

Put tread center marks on the rearmost points of the turning radius gauge.

Turn the steering wheel to the left and right full lock positions, and measure the turning angle.

- Wheel Angle (Unloaded Vehicle):

- Engine Tire Size Inside Wheel Outside Wheel Reference for TMC Made 2ZR-FE 195/65R15 38°13' +/- 2° (38.22° +/- 2°) 32°50' (32.83°) 205/55R16 except TMC Made 2ZR-FE 195/65R15 38°13' +/- 2° (38.22° +/- 2°) 32°50' (32.83°) 205/55R16 38°13' +/- 2° (38.22° +/- 2°)

38°31' +/- 2° (38.52° +/- 2°)*32°50' (32.83°)

33°04' (33.07°)*215/45R17 36°59' +/- 2° (36.98° +/- 2°) 32°01' (32.02°) 2AZ-FE 205/55R16* 37°19' +/- 2° (37.32° +/- 2°)* 32°18' (32.30°)* 215/45R17 36°59' +/- 2° (36.98° +/- 2°) 32°01' (32.02°)

- If the angles are not as specified, check and adjust the right and left rack end lengths.

| 4. INSPECT CAMBER, CASTER AND STEERING AXIS INCLINATION |

|

Install a camber-caster-kingpin gauge or place the front wheels on the center of a wheel alignment tester.

Inspect the camber, caster and steering axis inclination.

- Camber (Unloaded Vehicle):

- Engine Tire Size Camber Inclination Right-Left Difference for TMC Made 2ZR-FE 195/65R15 -0°35' +/- 45' (-0.58° +/- 0.75°) 45' (0.75°) or less 205/55R16 except TMC Made 2ZR-FE 195/65R15 - 0°34' +/- 45' (- 0.57° +/- 0.75°) 205/55R16 - 0°35' +/- 45' (- 0.58° +/- 0.75°)

- 0°26' +/- 45' (- 0.43° +/- 0.75°)*215/45R17 - 0°37' +/- 45' (- 0.62° +/- 0.75°) 2AZ-FE 205/55R16* - 0°27' +/- 45' (- 0.45° +/- 0.75°)* 215/45R17 - 0°37' +/- 45' (- 0.62° +/- 0.75°)

- Caster (Unloaded Vehicle):

- Engine Tire Size Caster Inclination Right-Left Difference for TMC Made 2ZR-FE 195/65R15 2°50' +/- 45' (2.83° +/- 0.75°) 45' (0.75°) or less 205/55R16 2°51' +/- 45' (2.85° +/- 0.75°) except TMC Made 2ZR-FE 195/65R15 2°50' +/- 45' (2.83° +/- 0.75°) 205/55R16 2°50' +/- 45' (2.83° +/- 0.75°)

2°41' +/- 45' (2.68° +/- 0.75°)*215/45R17 2°55' +/- 45' (2.92° +/- 0.75°) 2AZ-FE 205/55R16* 2°45' +/- 45' (2.75° +/- 0.75°)* 215/45R17 2°55' +/- 45' (2.92° +/- 0.75°)

- Steering Axis Inclination (Unloaded Vehicle):

- Engine Tire Size Steering Axis Inclination for TMC Made 2ZR-FE 195/65R15 12°32' (12.53°) 205/55R16 except TMC Made 2ZR-FE 195/65R15 12°32' (12.53°)

12°13' (12.22°)*205/55R16 215/45R17 12°37' (12.62°) 2AZ-FE 205/55R16* 12°16' (12.27°)* 215/45R17 12°37' (12.62°)

| 5. ADJUST CAMBER |

- NOTICE:

- Inspect toe-in after the camber has been adjusted.

Remove the front wheel.

Remove the bolt and separate the front flexible hose from the front shock absorber.

|

Remove the clamp and separate the front speed sensor from the front shock absorber (except TMC Made).

|

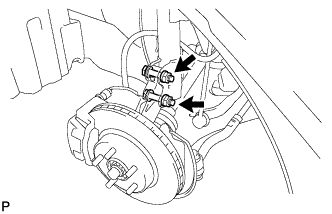

Remove the 2 nuts on the lower side of the front shock absorber.

- NOTICE:

- Keep the bolts inserted.

|

Clean the installation surfaces of the front shock absorber and the steering knuckle.

Temporarily install the 2 nuts (Step A).

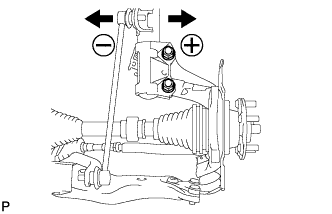

Fully push or pull the front axle hub in the direction of the required adjustment (Step B).

|

Tighten the nuts.

- Torque:

- 240 N*m{2448 kgf*cm, 176 ft.*lbf}

- NOTICE:

- Keep the bolts from rotating when tightening the nuts.

Install the front speed sensor with the clamp to the front shock absorber (except TMC Made).

|

Install the front flexible hose to the front shock absorber with the bolt.

- Torque:

- 29 N*m{296 kgf*cm, 21 ft.*lbf}

|

Install the front wheel.

- Torque:

- 103 N*m{1050 kgf*cm, 76 ft.*lbf}

Check the camber.

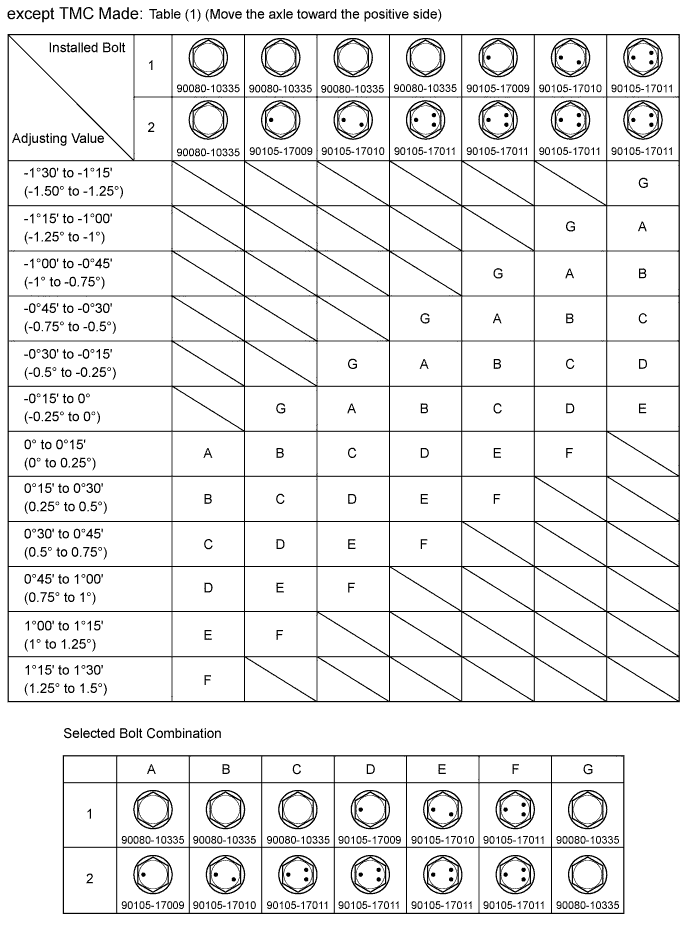

If the measured value is not within the specification, calculate the required adjustment amount using the formula below.

Camber adjustment amount = center value of the specified range - measured value

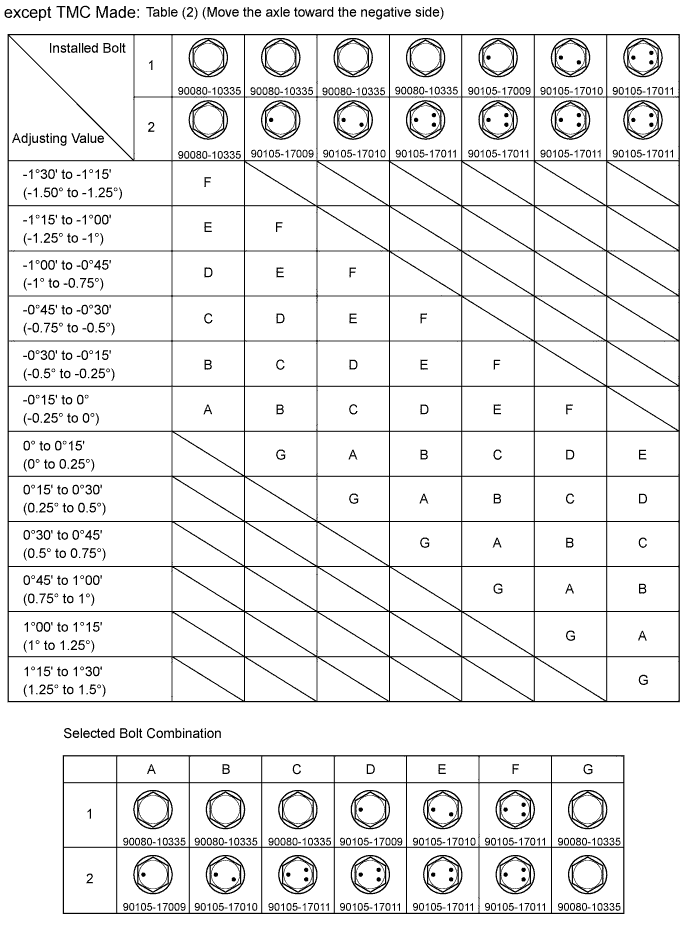

Check the combination of installed bolts. Select appropriate bolts from the table below to adjust the camber to the specified values.- HINT:

- Try to adjust the camber to the center of the specified values.

The body and suspension may be damaged if the camber is not correctly adjusted according to the table above.Move the Axle toward (+) in Step (B) Move the Axle toward (-) in Step (B) Refer to table (1) (Move the axle toward the positive side) Refer to table (2) (Move the axle toward the negative side) - NOTICE:

- Replace the nut with a new one when replacing the bolt.

|

Repeat the steps mentioned above. In step (A), replace 1 or 2 selected bolts.

- HINT:

- Replace 1 bolt at a time when replacing the 2 bolts.

| 6. INSPECT TOE-IN |

Bounce the vehicle up and down at the corners several times to stabilize the suspension.

Release the parking brake and move the shift lever to N.

Push the vehicle straight ahead approximately 5 m (16.4 ft.). (*1)

Put tread center marks on the rearmost points of the front wheels and measure the distance between the marks (dimension B).

|

Slowly push the vehicle straight ahead to rotate the front wheels 180° using the front tire valve as a reference point.

- HINT:

- Do not allow the wheels to rotate more than 180°. If the wheels rotate more than 180°, perform the procedure from (*1) again.

Measure the distance between the tread center marks on the front side of the wheels (dimension A).

- Toe-in:

Specified Condition C + D: 0°00' +/- 0°12' (0° +/- 0.2°)

B - A: 0 +/- 2.0 mm (0 +/- 0.0787 in.)

- HINT:

- Measure "B - A" only when "C + D" cannot be measured.

- If the toe-in is not within the specified range, adjust it at the rack ends.

|

| 7. ADJUST TOE-IN |

Make sure that the lengths of the right and left rack ends are almost the same.

- Difference between right and left rack ends:

- 1.5 mm (0.0591 in.) or less

|

Remove the boot clips.

Loosen the tie rod end lock nuts.

|

Turn the right and left rack ends by an equal amount to adjust the toe-in to the center value.

Extend the shorter rack end if the measured toe-in deviates toward the outer side.

Shorten the longer rack end if the measured toe-in deviates toward the inner side.

Tighten the tie rod end lock nuts.

- Torque:

- 74 N*m{755 kgf*cm, 55 ft.*lbf}

Place the boots on the seats and install the clips.

- HINT:

- Make sure that the boots are not twisted.

| 8. PLACE FRONT WHEELS FACING STRAIGHT AHEAD |

| 9. DISCONNECT CABLE FROM NEGATIVE BATTERY TERMINAL (w/ VSC) |

- NOTICE:

- Disconnect the cable from the negative (-) battery terminal for more than 2 seconds.

| 10. CONNECT CABLE TO NEGATIVE BATTERY TERMINAL (w/ VSC) |

| 11. PERFORM YAW RATE SENSOR ZERO POINT CALIBRATION (w/ VSC) |

| 12. CHECK STEERING ANGLE SENSOR ZERO POINT CALIBRATION (w/ VSC) |