TYPICAL MALFUNCTION THRESHOLDS

CHECK OTHER DTCS OUTPUT (IN ADDITION TO DTC P0746)

INSPECT SHIFT SOLENOID VALVE SL1

INSPECT TRANSMISSION VALVE BODY ASSEMBLY

INSPECT TORQUE CONVERTER ASSEMBLY

DTC P0746 Pressure Control Solenoid "A" Performance (Shift Solenoid Valve SL1) |

SYSTEM DESCRIPTION

The ECM uses signals from the vehicle speed sensor to detect the actual gear position (1st, 2nd, 3rd, 4th or 5th gear).Then the ECM compares the actual gear with the shift schedule in the ECM memory to detect mechanical problems of the shift solenoid valves, valve body or automatic transaxle (clutch, brake or gear etc.).

| DTC No. | DTC Detecting Condition | Trouble Area |

| P0746 | The gear required by the ECM does not match the actual gear when driving (2-trip detection logic) |

|

MONITOR DESCRIPTION

The ECM commands gear shifts by turning the shift solenoid valves "ON/OFF". According to the input shaft revolution, intermediate (counter) shaft revolution and output shaft revolution, the ECM detects the actual gear position (1st, 2nd, 3rd, 4th or 5th gear position). When the gear position commanded by the ECM and the actual gear position are not the same, the ECM illuminates the MIL, and stores the DTC.- HINT:

- Example:

- When either condition (a) or (b) is met, the ECM detects a malfunction.

- (a) The ECM commands the 1st gear, but the actual gear is 2nd.

- (b) The ECM commands the 2nd gear, but the actual gear is 1st.

MONITOR STRATEGY

| Related DTCs | P0746: Shift solenoid valve SL1/OFF malfunction Shift solenoid valve SL1/ON malfunction |

| Required sensors/Components | Shift solenoid valve SL1, Speed sensor (NT), Speed sensor (NC), Crankshaft position sensor (NE) |

| Frequency of operation | Continuous |

| Duration | 0.8 sec. |

| MIL operation | 2 driving cycles |

| Sequence of operation | None |

TYPICAL ENABLING CONDITIONS

| The monitor will run whenever this DTC is not present. (Not circuit malfunction) | P0712, P0713 (ATF temperature sensor circuit) P0115, P0117, P0118 (ECT sensor circuit) P0717 (Turbine speed sensor circuit) P0793 (Intermediate shaft speed sensor circuit) P0500 (Vehicle speed sensor circuit) P0748 (Shift solenoid valve SL1 circuit) P0778 (Shift solenoid valve SL2 circuit) P0798 (Shift solenoid valve SL3 circuit) P0982, P0983 (Shift solenoid valve S4 circuit) P0985, P0986 (Shift solenoid valve SR circuit) P2769, P2770 (Shift solenoid valve DSL circuit) P0120, P0121, P0122, P0123, P0220, P0222, P0223, P0604, P0606, P0607, P060A, P060D, P060E, P0657, P1607, P2102, P2103, P2111, P2112, P2118, P2119, P2135 (Electronic throttle system) |

| ECT (Engine coolant temperature) | 10°C (50°F) or more |

| Transmission range | "D" |

| TFT (Transmission fluid temperature) | -20°C (-4°F) or more |

| ECM selected gear | 1st |

| Vehicle speed | Less than 40 km/h (25 mph) |

| Throttle valve opening angle | 4.5% or more at engine speed 1900 rpm (Varies with engine speed) |

| ECM selected gear | 2nd |

| Throttle valve opening angle | 4.5% or more at engine speed 1900 rpm (Varies with engine speed) |

TYPICAL MALFUNCTION THRESHOLDS

Either of the following conditions is met: OFF malfunction or ON malfunction- 2 detections are necessary per driving cycle:

1st detection; temporary flag ON

2nd detection; pending fault code ONOFF malfunction: Input (turbine) speed/Intermediate shaft speed 1.49 to 1.63 ON malfunction: Input (turbine) speed/Intermediate shaft speed 2.72 to 2.86

INSPECTION PROCEDURE

- NOTICE:

- Perform the universal trip to clear permanent DTCs (COROLLA_ZRE142 RM000000W770S6X.html).

- HINT:

- Using Techstream to perform Active Test allows relays, VSVs, actuators and other items to be operated without removing any parts. This non-intrusive functional inspection can be very useful because intermittent operation may be discovered before parts or wiring is disturbed. Performing Active Test early in troubleshooting is one way to save diagnostic time. Data List information can be displayed while performing Active Test.

| PERFORM ACTIVE TEST |

Warm up the engine.

Turn the ignition switch off.

Connect Techstream to the DLC3.

Turn the ignition switch to the on position.

Turn on the tester.

Select the item "Powertrain / Engine and ECT / Active Test / Shift Status".

According to the display on the tester, perform the "Active Test".

- HINT:

- While driving, the shift position can be forcibly changed with Techstream.

- Comparing the shift position commanded by the Active Test with the actual shift position enables you to confirm the problem (COROLLA_ZRE142 RM000000O8L0N2X.html).

Tester Display Test Part Control Range Diagnostic Note Control the Shift Position [Test Details]

Operate the shift solenoid valve and set each shift position by yourself.

[Vehicle Condition]- IDL: ON

- Less than 50 km/h (31 mph)

- Press "→" button: Shift up

- Press "←" button: Shift down

1st/2nd/3rd/4th/5th Possible to check the operation of the shift solenoid valves. - HINT:

- This test can be conducted when the vehicle speed is 50 km/h (31 mph) or less.

- The shift position commanded by the ECM is shown in the Data List / Shift Status display on Techstream.

| 1.CHECK OTHER DTCS OUTPUT (IN ADDITION TO DTC P0746) |

Connect Techstream to the DLC3.

Turn the ignition switch to the on position and turn the Techstream main switch ON.

When you use Techstream:

Select the item "Powertrain / Engine and ECT / Trouble Codes".

Read the DTCs using Techstream.

- Result:

Display (DTC output) Proceed to Only "P0746" is output A "P0746" and other DTCs B

- HINT:

- If any other codes besides "P0746" are output, perform the troubleshooting for those DTCs first.

|

| ||||

| A | |

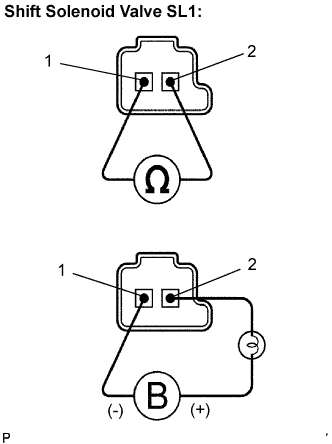

| 2.INSPECT SHIFT SOLENOID VALVE SL1 |

Remove the shift solenoid valve SL1.

|

Measure the resistance according to the value(s) in the table below.

- Standard resistance:

Tester Connection Condition Specified Condition 1 - 2 20°C (68°F) 5.0 to 5.6 Ω

Connect the positive (+) lead with a 21 W bulb to terminal 2 and the negative (-) lead to terminal 1 of the solenoid valve connector, then check the movement of the valve.

- OK:

- The solenoid makes an operating sound.

|

| ||||

| OK | |

| 3.INSPECT TRANSMISSION VALVE BODY ASSEMBLY |

- OK:

- There are no foreign objects on each valve and they operate smoothly.

|

| ||||

| OK | |

| 4.INSPECT TORQUE CONVERTER ASSEMBLY |

- OK:

- The torque converter assembly operates normally.

|

| ||||

| OK | ||

| ||