Automatic Transaxle Unit Disassembly

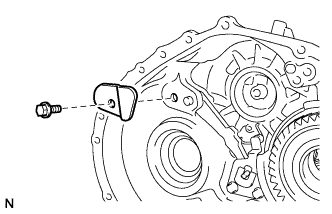

REMOVE NO. 2 BREATHER PLUG

REMOVE PARK/NEUTRAL POSITION SWITCH ASSEMBLY

REMOVE OIL COOLER TUBE UNION (INLET OIL COOLER UNION)

REMOVE OIL COOLER TUBE UNION (OUTLET OIL COOLER UNION)

REMOVE NO. 1 TRANSAXLE CASE PLUG

FIX AUTOMATIC TRANSAXLE ASSEMBLY

REMOVE AUTOMATIC TRANSAXLE OIL PAN SUB-ASSEMBLY

INSPECT TRANSMISSION OIL CLEANER MAGNET

REMOVE VALVE BODY OIL STRAINER ASSEMBLY

REMOVE TRANSMISSION VALVE BODY ASSEMBLY

REMOVE TRANSAXLE CASE GASKET

INSPECT INPUT SHAFT SUB-ASSEMBLY

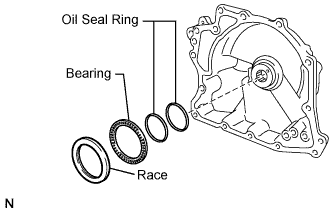

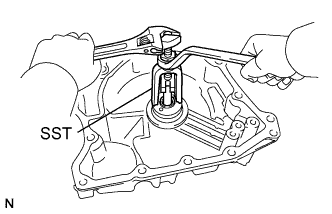

REMOVE TRANSAXLE REAR COVER SUB-ASSEMBLY

REMOVE DIRECT MULTIPLE DISC CLUTCH ASSEMBLY

REMOVE DIRECT MULTIPLE DISC CLUTCH SNAP RING

REMOVE NO. 2 DIRECT MULTIPLE DISC CLUTCH FLANGE

INSPECT NO. 2 CLUTCH DISC

REMOVE REAR PLANETARY SUN GEAR ASSEMBLY

INSPECT REAR PLANETARY SUN GEAR ASSEMBLY

REMOVE NO. 1 DIRECT MULTIPLE DISC CLUTCH FLANGE

INSPECT NO. 1 CLUTCH DISC

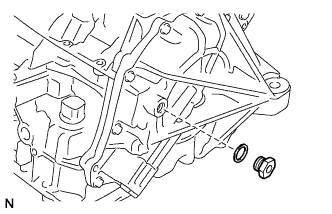

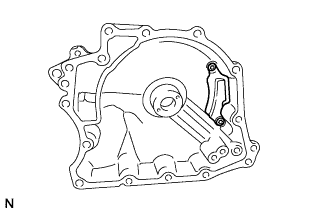

REMOVE TRANSAXLE HOUSING

REMOVE COUNTER DRIVEN GEAR FRONT TAPERED ROLLER BEARING OUTER RACE

REMOVE DIFFERENTIAL GEAR LUBE APPLY TUBE

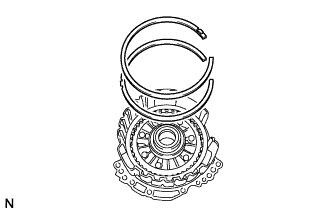

REMOVE FRONT OIL PUMP AND GEAR BODY SUB-ASSEMBLY

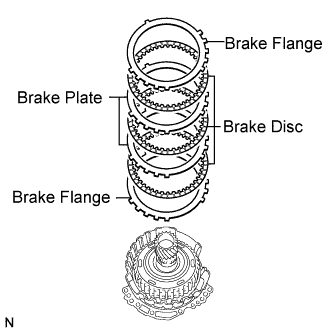

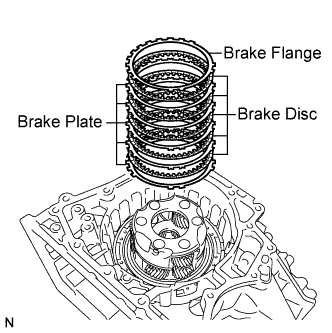

REMOVE NO. 3 BRAKE DISC

INSPECT NO. 3 BRAKE DISC

REMOVE UNDERDRIVE PLANETARY GEAR ASSEMBLY

REMOVE NO. 3 BRAKE HUB

REMOVE UNDERDRIVE PLANETARY RING GEAR

REMOVE PLANETARY SUN GEAR SUB-ASSEMBLY

INSPECT UNDERDRIVE PLANETARY GEAR ASSEMBLY

INSPECT PLANETARY SUN GEAR SUB-ASSEMBLY

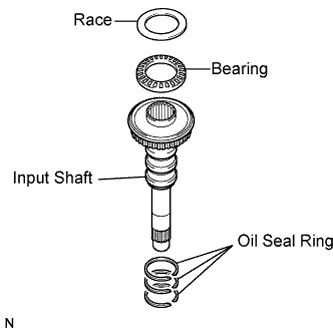

REMOVE INPUT SHAFT SUB-ASSEMBLY

REMOVE UNDERDRIVE PLANETARY SUN GEAR

REMOVE NO. 1 BRAKE DISC

INSPECT NO. 1 BRAKE DISC

REMOVE 2ND BRAKE PISTON RETURN SPRING SUB-ASSEMBLY

INSPECT 2ND BRAKE PISTON RETURN SPRING SUB-ASSEMBLY

REMOVE NO. 1 BRAKE PISTON

REMOVE FRONT DIFFERENTIAL CASE

REMOVE COUNTER DRIVE GEAR NUT

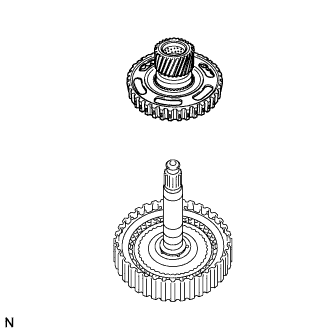

REMOVE COUNTER DRIVEN GEAR

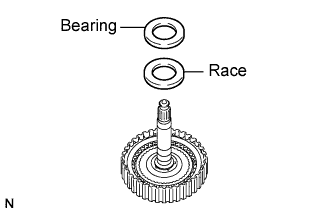

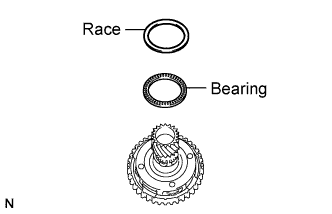

REMOVE COUNTER DRIVEN GEAR FRONT TAPERED ROLLER BEARING

REMOVE COUNTER DRIVEN GEAR REAR TAPERED ROLLER BEARING

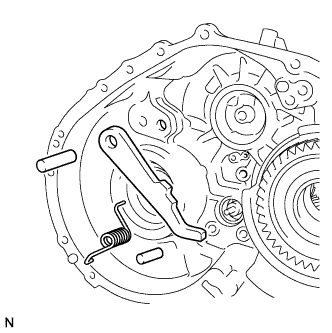

REMOVE PAWL SHAFT CLAMP

REMOVE PAWL STOPPER PLATE

REMOVE PARKING LOCK SLEEVE

REMOVE PARKING LOCK PAWL

REMOVE COUNTER DRIVEN GEAR REAR TAPERED ROLLER BEARING OUTER RACE

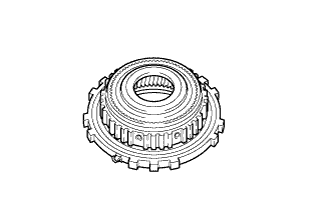

REMOVE ONE-WAY CLUTCH ASSEMBLY

INSPECT ONE-WAY CLUTCH ASSEMBLY

REMOVE PLANETARY RING GEAR

REMOVE PLANETARY RING GEAR FLANGE

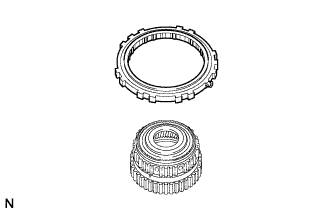

REMOVE NO. 2 BRAKE DISC

INSPECT NO. 2 BRAKE DISC

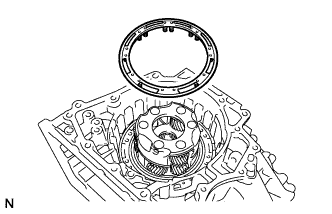

REMOVE 1ST AND REVERSE BRAKE RETURN SPRING SUB-ASSEMBLY

INSPECT 1ST AND REVERSE BRAKE RETURN SPRING SUB-ASSEMBLY

REMOVE NO. 2 BRAKE PISTON

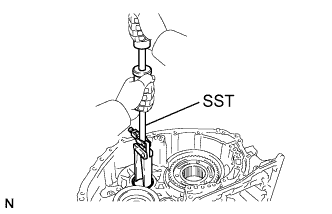

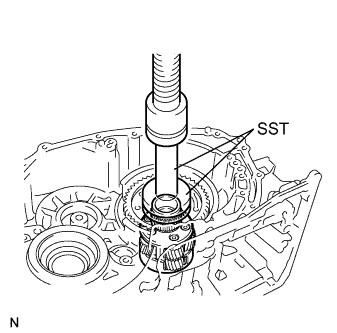

REMOVE PLANETARY GEAR ASSEMBLY

REMOVE COUNTER DRIVE GEAR

REMOVE NO. 3 BRAKE PISTON

REMOVE MANUAL DETENT SPRING SUB-ASSEMBLY

REMOVE PARKING LOCK ROD SUB-ASSEMBLY

REMOVE MANUAL VALVE LEVER SHAFT

REMOVE MANUAL VALVE LEVER SHAFT OIL SEAL

Automatic Transaxle Unit -- Disassembly |

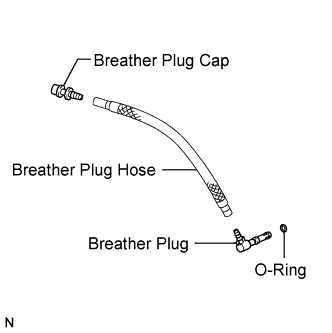

| 1. REMOVE NO. 2 BREATHER PLUG |

Using a screwdriver, remove the breather plug hose from the transaxle case.

Using a screwdriver, remove the breather plug from the breather plug hose.

Using a screwdriver, remove the O-ring from the breather plug.

Using a screwdriver, remove the breather plug cap from the breather breather plug hose.

| 2. REMOVE PARK/NEUTRAL POSITION SWITCH ASSEMBLY |

Remove the nut, washer, and control shaft lever from the control shaft.

Remove the 2 bolts and the park/neutral position switch assembly from the transaxle case.

- NOTICE:

- Before removing the park/neutral position switch, remove any dirt or rust on the installation portion of the control shaft. Be sure to remove the switch straight along the shaft while being careful not to deform the plate spring that supports the shaft. If the plate spring is deformed, the park/neutral switch cannot be reinstalled correctly.

| 3. REMOVE OIL COOLER TUBE UNION (INLET OIL COOLER UNION) |

Loosen the nut while holding the oil cooler tube union (inlet oil cooler union).

Remove the oil cooler tube union (inlet oil cooler union) from the transaxle case.

Remove the O-ring from the oil cooler tube union (inlet oil cooler union).

| 4. REMOVE OIL COOLER TUBE UNION (OUTLET OIL COOLER UNION) |

Loosen the nut while holding the oil cooler tube union (outlet oil cooler union).

Remove the oil cooler tube union (outlet oil cooler union) from the transaxle case.

Remove the O-ring from the oil cooler tube union (outlet oil cooler union).

| 5. REMOVE NO. 1 TRANSAXLE CASE PLUG |

Remove the 3 No. 1 transaxle case plugs from the transaxle case.

Using a screwdriver, remove the 3 O-rings from the 3 No. 1 transaxle case plugs.

Using a hexagon wrench (6 mm), remove the 3 hexagon bolts from the transaxle housing.

Remove the 3 gaskets from the 3 hexagon bolts.

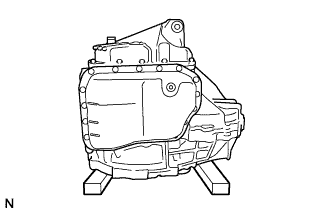

| 6. FIX AUTOMATIC TRANSAXLE ASSEMBLY |

Secure the transaxle assembly on wooden blocks.

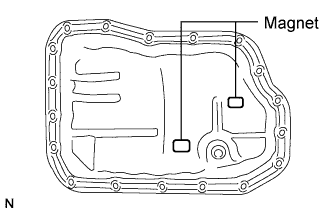

| 7. REMOVE AUTOMATIC TRANSAXLE OIL PAN SUB-ASSEMBLY |

Using a hexagon wrench (6 mm), remove the overflow plug from the automatic transaxle oil pan sub-assembly.

Remove the gasket from the overflow plug.

Using a hexagon wrench (6 mm), remove the No. 1 oil filler tube from the automatic transaxle assembly.

Remove the 18 bolts, automatic transaxle oil pan sub-assembly, and gasket from the automatic transaxle assembly.

Remove the 2 magnets from the automatic transaxle oil pan sub-assembly.

| 8. INSPECT TRANSMISSION OIL CLEANER MAGNET |

Use the removed magnets to collect any steel chips. Examine the chips and particles in the pan and on the magnets to determine what type of wear has occurred in the transaxle:

- Result:

- Steel (magnetic):

- Bearing, gear and plate wear

- Brass (non-magnetic):

- Bearing wear

| 9. REMOVE VALVE BODY OIL STRAINER ASSEMBLY |

Remove the 2 bolts and oil strainer assembly from the valve body assembly.

Remove the O-ring from the oil strainer assembly.

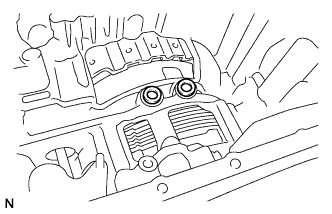

| 10. REMOVE TRANSMISSION VALVE BODY ASSEMBLY |

Remove the 11 bolts and valve body assembly from the transaxle case.

- NOTICE:

- When removing the transmission valve body assembly, be careful not to allow the transmission revolution sensor and the transaxle case to interfere each other.

| 11. REMOVE TRANSAXLE CASE GASKET |

Remove the 2 gaskets from the transaxle case.

| 12. INSPECT INPUT SHAFT SUB-ASSEMBLY |

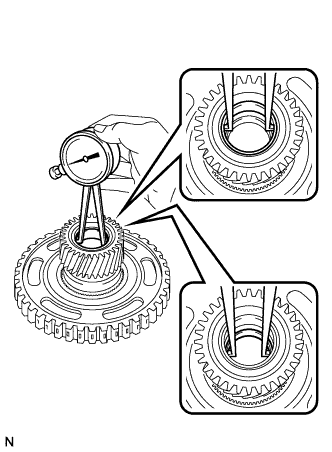

Using a dial indicator, measure the input shaft end play.

- End play:

- 0.012 to 1.250 mm (0.0005 to 0.0492 in.)

| 13. REMOVE TRANSAXLE REAR COVER SUB-ASSEMBLY |

Remove the refill plug from the transaxle rear cover.

Remove the gasket from the refill plug.

Remove the 2 No. 1 automatic transaxle case plugs from the transaxle rear cover.

Using a screwdriver, remove the 2 O-rings from the 2 No. 1 automatic transaxle case plugs.

Remove the 14 bolts from the transaxle rear cover.

Using a brass bar and hammer, tap on the circumference of the rear transaxle cover, to remove the transaxle rear cover from the transaxle case.

Using a screwdriver, remove the 3 O-rings from the transaxle case.

Using a screwdriver, remove the 2 oil seal rings from the transaxle rear cover.

Remove the thrust needle roller bearing and thrust needle roller race from the transaxle rear cover.

Using a "TORX" wrench (T30), remove the 2 "TORX" screws and transaxle rear cover plate from the transaxle rear cover.

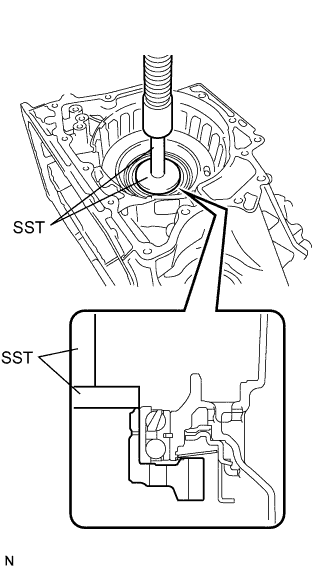

Using SST, remove the needle roller bearing from the transaxle rear cover.

- SST

- 09319-60020

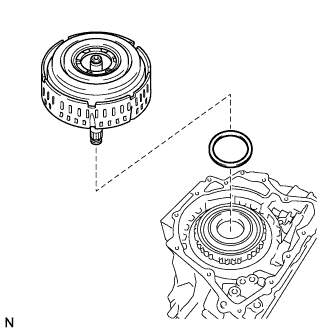

| 14. REMOVE DIRECT MULTIPLE DISC CLUTCH ASSEMBLY |

Remove the direct multiple disc clutch assembly from the transaxle case.

Remove the thrust needle roller bearing from the direct multiple disc clutch assembly.

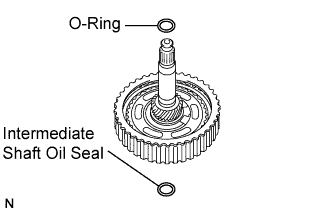

| 15. REMOVE DIRECT MULTIPLE DISC CLUTCH SNAP RING |

Using 2 screwdrivers, remove the snap ring from the direct multiple disc clutch assembly.

Remove the No. 2 direct clutch piston from the direct multiple disc clutch assembly.

Using a screwdriver, remove the intermediate shaft oil seal ring from the direct No. 2 direct clutch piston.

Using a screwdriver, remove the O-ring from the direct multiple disc clutch assembly.

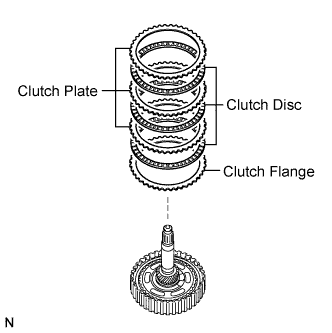

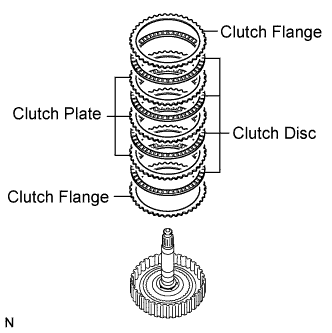

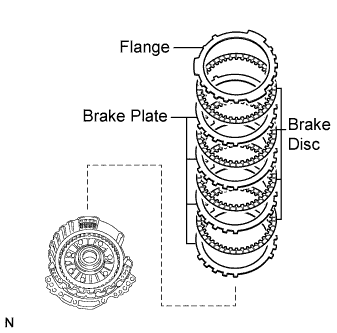

| 16. REMOVE NO. 2 DIRECT MULTIPLE DISC CLUTCH FLANGE |

Remove the flange, 3 clutch discs and 3 clutch plates from the direct multiple disc clutch assembly.

| 17. INSPECT NO. 2 CLUTCH DISC |

Check if the sliding surfaces of the discs, plates, and flange are worn or burnt. If necessary, replace them.

- NOTICE:

- If the linings of the discs are peeled off or discolored, or even if a part of the groove is damaged, replace all discs.

| 18. REMOVE REAR PLANETARY SUN GEAR ASSEMBLY |

Using a snap ring expander, remove the snap ring from the direct multiple disc clutch assembly.

Remove the rear planetary sun gear from the direct multiple disc clutch assembly.

Remove the thrust needle roller bearing and thrust needle roller race from the direct multiple disc clutch assembly.

| 19. INSPECT REAR PLANETARY SUN GEAR ASSEMBLY |

Using a dial indicator, measure the inside diameter of the bushing of the rear planetary sun gear sub-assembly.

- Standard inside diameter:

- 25.580 to 25.601 mm (1.0071 to 1.0079 in.)

- Maximum inside diameter:

- 25.601 mm (1.0079 in.)

If the inside diameter is greater than the maximum, replace the rear planetary sun gear sub-assembly.

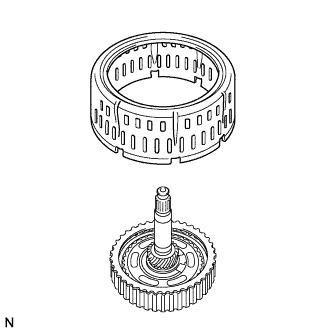

| 20. REMOVE NO. 1 DIRECT MULTIPLE DISC CLUTCH FLANGE |

Using 2 screwdrivers, remove the 2 snap rings from the direct multiple disc clutch assembly.

Remove the flange, 4 clutch discs, and 4 clutch plates from the direct multiple disc clutch assembly.

| 21. INSPECT NO. 1 CLUTCH DISC |

Check if the sliding surfaces of the discs, plates, and flange are worn or burnt. If necessary, replace them.

- NOTICE:

- If the linings of the discs are peeled off or discolored, or even if a part of the groove is damaged, replace all discs.

| 22. REMOVE TRANSAXLE HOUSING |

Remove the 20 bolts from the transaxle housing.

Using a brass bar and hammer, tap on the circumference of the transaxle housing to remove the transaxle housing from the transaxle case.

| 23. REMOVE COUNTER DRIVEN GEAR FRONT TAPERED ROLLER BEARING OUTER RACE |

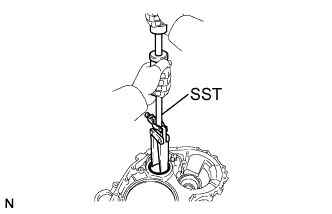

Using SST, remove the counter driven gear front tapered roller bearing outer race and shim from the transaxle housing.

- SST

- 09308-00010

| 24. REMOVE DIFFERENTIAL GEAR LUBE APPLY TUBE |

Remove the bolt, clamp, and differential gear lube apply tube from the transaxle housing.

| 25. REMOVE FRONT OIL PUMP AND GEAR BODY SUB-ASSEMBLY |

Remove the 7 bolts and oil pump from the transaxle case.

Remove the O-ring from the oil pump assembly.

Remove the thrust needle roller bearing and thrust needle roller race from the carrier lock nut.

Remove the O-ring from the transaxle case.

| 26. REMOVE NO. 3 BRAKE DISC |

Using a screwdriver, remove the snap ring from the oil pump assembly.

Remove the 2 brake flanges, 3 brake discs, and 2 brake plates from the oil pump assembly.

| 27. INSPECT NO. 3 BRAKE DISC |

Check if the sliding surfaces of the discs, plates, and flange are worn or burnt. If necessary, replace them.

- NOTICE:

- If the linings of the discs are peeled off or discolored, or even if a part of the groove is damaged, replace all discs.

| 28. REMOVE UNDERDRIVE PLANETARY GEAR ASSEMBLY |

Remove the underdrive planetary gear assembly from the oil pump assembly.

| 29. REMOVE NO. 3 BRAKE HUB |

Remove the No. 3 brake hub from the underdrive planetary gear assembly.

Remove the thrust needle roller bearing and thrust needle roller race from the underdrive planetary gear assembly.

| 30. REMOVE UNDERDRIVE PLANETARY RING GEAR |

Using needle-nose pliers, remove the snap ring from the underdrive planetary ring gear.

Remove the underdrive planetary ring gear from the underdrive planetary gear assembly.

| 31. REMOVE PLANETARY SUN GEAR SUB-ASSEMBLY |

While expanding the snap ring with snap ring pliers, remove the front planetary sun gear from the underdrive planetary gear assembly.

Remove the snap ring from the underdrive planetary gear assembly.

| 32. INSPECT UNDERDRIVE PLANETARY GEAR ASSEMBLY |

Using a feeler gauge, measure the clearance between the underdrive planetary gear and the pinion gear at 4 points.

- Standard clearance:

- 0.18 to 0.54 mm (0.0071 to 0.0213 in.)

If the clearance is greater than the standard clearance, replace the underdrive planetary gear sun gear.

| 33. INSPECT PLANETARY SUN GEAR SUB-ASSEMBLY |

Using a dial indicator, measure the inside diameter of the bushings of the planetary sun gear.

- Standard inside diameter:

- 25.525 to 25.546 mm (1.0049 to 1.0057 in.)

- Maximum inside diameter:

- 25.546 mm (1.0057 in.)

If the inside diameter is greater than the maximum, replace the planetary gear sun gear.

| 34. REMOVE INPUT SHAFT SUB-ASSEMBLY |

Remove the input shaft from the oil pump assembly.

Remove the thrust needle roller bearing and thrust needle roller race from the input shaft.

Using a screwdriver, remove the 3 input shaft oil seal rings from the input shaft.

| 35. REMOVE UNDERDRIVE PLANETARY SUN GEAR |

Remove the underdrive planetary sun gear from the oil pump assembly.

Remove the thrust needle roller bearing from the oil pump assembly.

| 36. REMOVE NO. 1 BRAKE DISC |

Using a screwdriver, remove the 2 snap rings from the oil pump assembly.

Remove the flange, 4 brake discs, and 4 brake plates from the oil pump assembly.

| 37. INSPECT NO. 1 BRAKE DISC |

Check if the sliding surfaces of the discs, plates, and flange are worn or burnt. If necessary, replace them.

- NOTICE:

- If the linings of the discs are peeled off or discolored, or even if a part of the groove is damaged, replace all discs.

| 38. REMOVE 2ND BRAKE PISTON RETURN SPRING SUB-ASSEMBLY |

Remove the 3 2nd brake piston return springs from the oil pump assembly.

| 39. INSPECT 2ND BRAKE PISTON RETURN SPRING SUB-ASSEMBLY |

Using vernier calipers, measure the free length of the 3 2nd brake piston return springs including the spring seats.

- Standard free length:

- 23.85 mm (0.9390 in.)

If the free length is shorter than the standard free length, replace the 2nd brake piston return spring.

| 40. REMOVE NO. 1 BRAKE PISTON |

Holding the oil pump assembly by hand, apply compressed air (392 kPa, 4.0 kgf/cm2, 57 psi) to the oil pump assembly to remove the No. 1 brake piston.

Using a screwdriver, remove the 2 O-rings from the No. 1 brake piston.

| 41. REMOVE FRONT DIFFERENTIAL CASE |

Remove the differential case sub-assembly from the transaxle case.

| 42. REMOVE COUNTER DRIVE GEAR NUT |

Using a SST and hammer, unstake the nut.

- SST

- 09930-00010

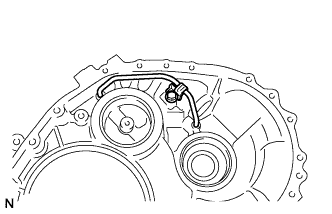

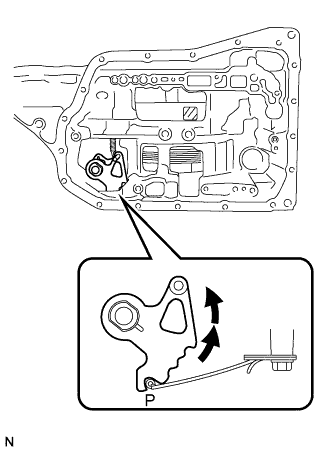

Turn the manual valve lever 2 notches counterclockwise to set it in the P position as shown in the illustration.

Using SST, remove the nut from the planetary gear assembly.

- SST

- 09387-00130

| 43. REMOVE COUNTER DRIVEN GEAR |

Turn the manual valve lever 2 notches clockwise to set it in the N position as shown in the illustration.

Remove the counter driven gear sub-assembly from the transaxle case.

| 44. REMOVE COUNTER DRIVEN GEAR FRONT TAPERED ROLLER BEARING |

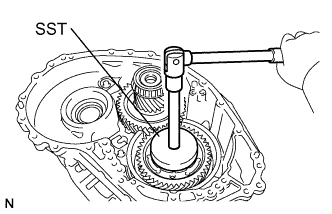

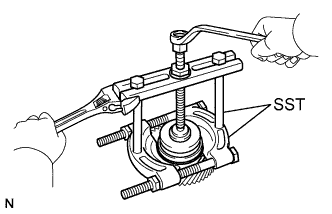

Using SST, remove the counter driven gear front tapered roller bearing from the counter driven gear sub-assembly.

- SST

- 09950-00020

09950-00030

09950-60010(09951-00400)

| 45. REMOVE COUNTER DRIVEN GEAR REAR TAPERED ROLLER BEARING |

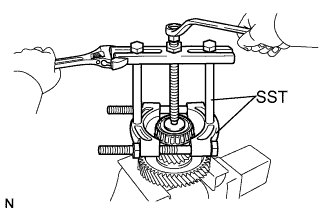

Using SST, remove the counter driven gear rear tapered roller bearing and differential drive pinion from the counter driven gear.

- SST

- 09950-40011(09951-04010,09952-04010,09954-04010,09953-04020,09955-04071,09957-04010,09958-04011)

09950-60010(09951-00320)

| 46. REMOVE PAWL SHAFT CLAMP |

Remove the bolt and pawl shaft clamp from the transaxle case.

| 47. REMOVE PAWL STOPPER PLATE |

Remove the 2 bolts and pawl stopper plate from the transaxle case.

| 48. REMOVE PARKING LOCK SLEEVE |

Remove the parking lock sleeve from the transaxle case.

| 49. REMOVE PARKING LOCK PAWL |

Remove the spring, parking lock pawl pin, parking lock pawl shaft, and parking lock pawl from the transaxle case.

| 50. REMOVE COUNTER DRIVEN GEAR REAR TAPERED ROLLER BEARING OUTER RACE |

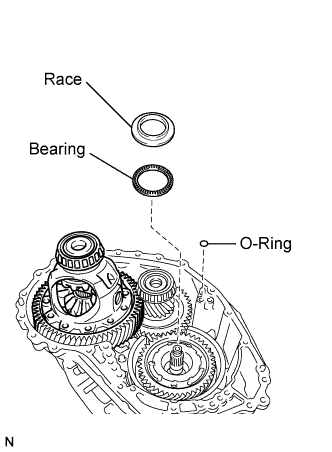

Using SST, remove the counter driven gear rear tapered roller bearing outer race from the transaxle case.

- SST

- 09308-00010

| 51. REMOVE ONE-WAY CLUTCH ASSEMBLY |

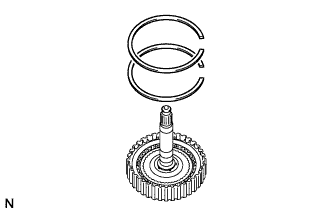

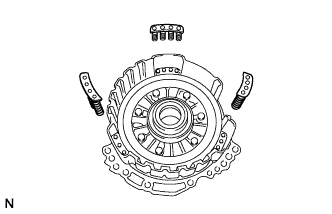

Using a screwdriver, remove the snap ring from the transaxle case.

Remove the one-way clutch assembly with planetary ring gear from the transaxle case.

Remove the thrust needle roller bearing from the transaxle case.

| 52. INSPECT ONE-WAY CLUTCH ASSEMBLY |

Temporarily install the one-way clutch assembly to the planetary ring gear.

Rotate the one-way clutch assembly to check the rotating direction for lock or free operation.

If the one-way clutch assembly does not operate normally, replace it.

| 53. REMOVE PLANETARY RING GEAR |

Remove the planetary ring gear from the one-way clutch assembly.

| 54. REMOVE PLANETARY RING GEAR FLANGE |

Using a screwdriver, remove the snap ring from the planetary ring gear.

Remove the planetary ring gear flange from the planetary ring gear.

| 55. REMOVE NO. 2 BRAKE DISC |

Using a screwdriver, remove the snap ring from the transaxle case.

Remove the brake flange, 5 brake discs, and 5 brake plates from the transaxle case.

| 56. INSPECT NO. 2 BRAKE DISC |

Check if the sliding surfaces of the discs, plates, and flange are worn or burnt. If necessary, replace them.

- NOTICE:

- If the linings of the discs are peeled off or discolored, or even if a part of the groove is damaged, replace all discs.

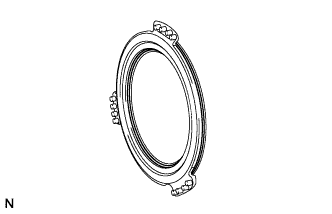

| 57. REMOVE 1ST AND REVERSE BRAKE RETURN SPRING SUB-ASSEMBLY |

Using a screwdriver, remove the snap ring from the transaxle case.

Remove the 1st and reverse brake return spring from the transaxle case.

| 58. INSPECT 1ST AND REVERSE BRAKE RETURN SPRING SUB-ASSEMBLY |

Using vernier calipers, measure the free length of the 1st and reverse brake return spring together with the spring seat.

- Standard free length:

- 15.79 mm (0.6217 in.)

If the free length is shorter than the standard free length, replace the 1st and reverse brake return spring.

| 59. REMOVE NO. 2 BRAKE PISTON |

Apply compressed air (392 kPa, 4.0 kgf/cm2, 57 psi) to the ATF hole indicated by the arrow to remove the No. 2 brake piston assembly from the transaxle case.

Using a screwdriver, remove the 2 O-rings from the No. 2 brake piston.

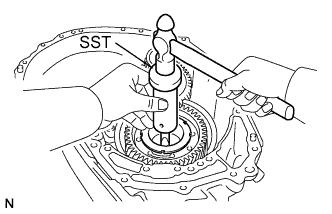

| 60. REMOVE PLANETARY GEAR ASSEMBLY |

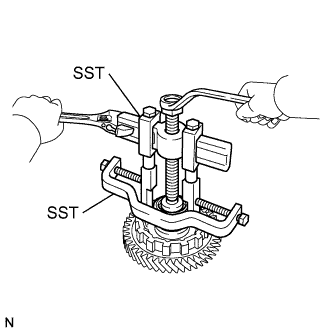

Using SST and a press, remove the planetary gear assembly from the transaxle case.

- SST

- 09950-60010(09951-00580)

09950-70010(09951-07100)

| 61. REMOVE COUNTER DRIVE GEAR |

Using SST and a press, remove the counter drive gear and bearing inner race (rear side) from the transaxle case.

- SST

- 09950-60020(09951-00710)

09950-70010(09951-07100)

As shown in the illustration, tighten the 3 bolts evenly and leave a clearance of approximately 20.0 mm (0.797 in.) between the counter drive gear and inner race.

Using SST, remove the bearing inner race (front side) from the counter drive gear.

- SST

- 09950-00020

09950-00030

09950-60020(09951-00710)

| 62. REMOVE NO. 3 BRAKE PISTON |

Using a screwdriver, remove the snap ring from the transaxle case.

Remove the brake piston return spring from the transaxle case.

Remove the No. 3 brake piston from the transaxle case.

| 63. REMOVE MANUAL DETENT SPRING SUB-ASSEMBLY |

Remove the bolt, cover, and manual detent spring sub-assembly from the transaxle case.

| 64. REMOVE PARKING LOCK ROD SUB-ASSEMBLY |

Remove the parking lock rod sub-assembly from the parking lock lever sub-assembly.

- HINT:

- Align the dial with the notches on the parking lock lever sub-assembly to remove the parking lock rod sub-assembly.

| 65. REMOVE MANUAL VALVE LEVER SHAFT |

Using needle-nose pliers, remove the manual valve lever shaft retainer spring from the transaxle case.

Using a screwdriver, slide the spacer of the manual valve lever sub-assembly.

Using a pin punch (3 mm) and hammer, drive out the slotted spring pin from the manual valve lever sub-assembly.

- HINT:

- Slowly drive out the pin so that it will not fall into the transaxle case.

Using a screwdriver, slide the spacer of the parking lock lever sub-assembly.

Using a pin punch (3 mm) and hammer, drive out the slotted spring pin from the parking lock lever sub-assembly.

- HINT:

- Slowly drive out the pin so that it will not fall into the transaxle case.

Remove the manual valve lever shaft, manual valve lever sub-assembly, parking lock lever sub-assembly and 2 spacers from the transaxle case.

| 66. REMOVE MANUAL VALVE LEVER SHAFT OIL SEAL |

Using a screwdriver, remove the manual valve lever shaft oil seal from the transaxle case.