Sfi System Active Control Engine Mount System

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

CHECK VACUUM HOSES

CHECK VACUUM

INSPECT DUTY VACUUM SWITCHING VALVE (OPERATION)

INSPECT DUTY VACUUM SWITCHING VALVE (RESISTANCE)

INSPECT FRONT ENGINE MOUNTING INSULATOR ASSEMBLY

CHECK HARNESS AND CONNECTOR (VSV FOR ACM - ECM)

INSPECT DUTY VACUUM SWITCHING VALVE (VOLTAGE)

CHECK HARNESS AND CONNECTOR (VSV FOR ACM - ENGINE JUNCTION BLOCK (EFI RELAY))

INSPECT ENGINE ROOM JUNCTION BLOCK (EFI RELAY)

SFI SYSTEM - Active Control Engine Mount System |

DESCRIPTION

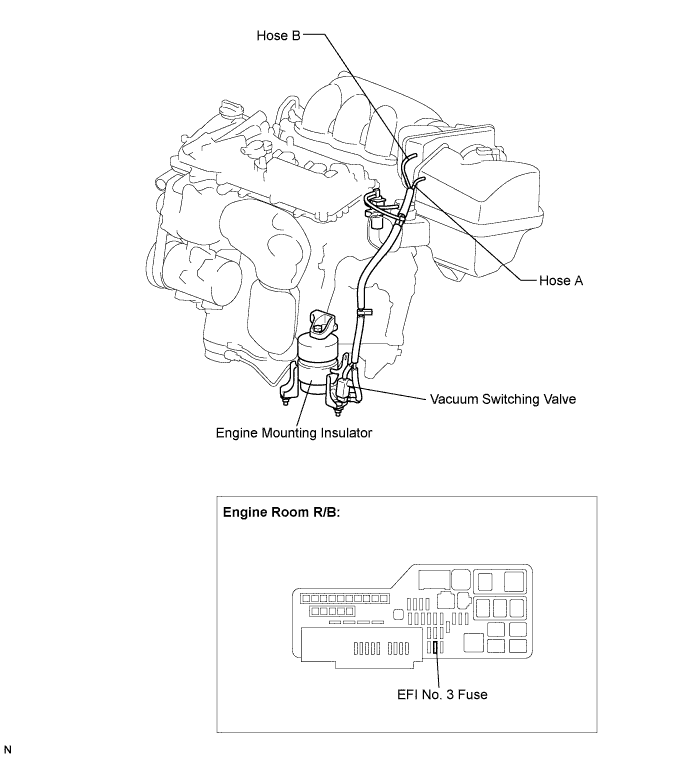

- LOCATION

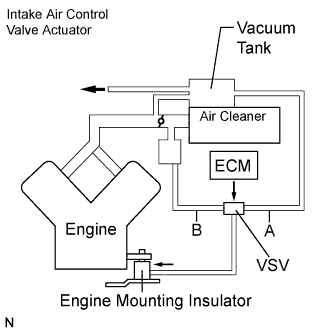

The Active Control Engine Mount (ACM) system decreases engine vibration at a low engine speed using the ACM VSV. The VSV is controlled by a pulse signal transmitted to the VSV from the ECM. The frequency of this pulse signal is matched to the engine speed to decrease engine vibration.

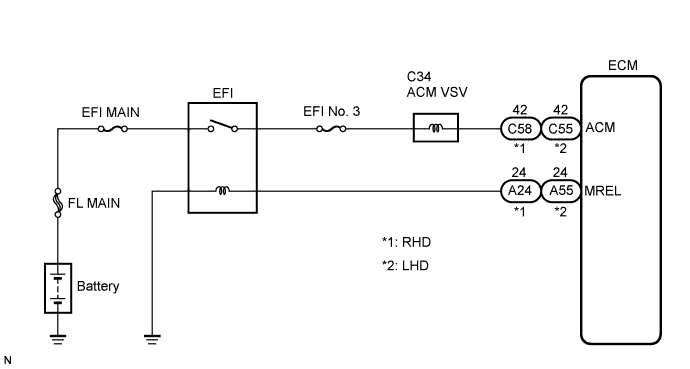

WIRING DIAGRAM

INSPECTION PROCEDURE

If the hose is damaged, replace the vacuum hose assembly.

Check the air and vacuum hoses for looseness, disconnection and blockage.

| | REPAIR OR REPLACE VACUUM HOSES |

|

|

Start the engine.

Disconnect the vacuum hose from the air cleaner cap.

Check that the disconnected port located on the vacuum tank applies suction to your finger.

- OK:

- Vacuum pressure exists.

Reconnect the vacuum hose.

| | CHECK AND REPLACE VACUUM SOURCE AND HOSES |

|

|

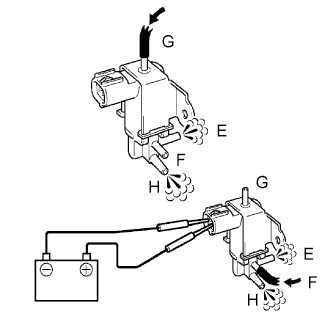

| 3.INSPECT DUTY VACUUM SWITCHING VALVE (OPERATION) |

Remove the VSV for ACM.

Check operation of the VSV for ACM when positive battery voltage is applied to the terminals of the VSV for ACM connector.

- Positive battery voltage is not applied:

- The air from pipe G is flowing out through pipes E and H.

- Positive battery voltage is applied:

- The air from pipe F is flowing out through pipes E and H.

Reinstall the VSV for ACM.

| | REPLACE DUTY VACUUM SWITCHING VALVE |

|

|

| 4.INSPECT DUTY VACUUM SWITCHING VALVE (RESISTANCE) |

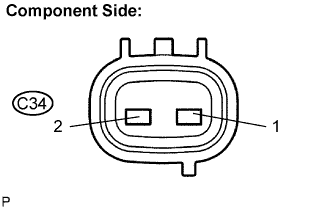

Disconnect the C34 VSV for ACM connector.

Measure the resistance between terminals 1 and 2.

- Standard resistance:

- 19 to 21 Ω at 20°C (68°F)

Reconnect the VSV for ACM connector.

| | REPLACE DUTY VACUUM SWITCHING VALVE |

|

|

| 5.INSPECT FRONT ENGINE MOUNTING INSULATOR ASSEMBLY |

Disconnect the vacuum hose from the front engine mounting insulator.

Using a vacuum pump, apply vacuum of 80 kPa (600 mmHg, 25 in.Hg) and wait for 1 minute.

Check that there is no change in the needle movement of the vacuum pump gauge.

Check that there is no fluid leakage caused by a break in the diaphragm.

- OK:

- Vacuum pressure exists.

Reconnect the vacuum hose.

| | REPLACE FRONT ENGINE MOUNTING INSULATOR ASSEMBLY |

|

|

| 6.CHECK HARNESS AND CONNECTOR (VSV FOR ACM - ECM) |

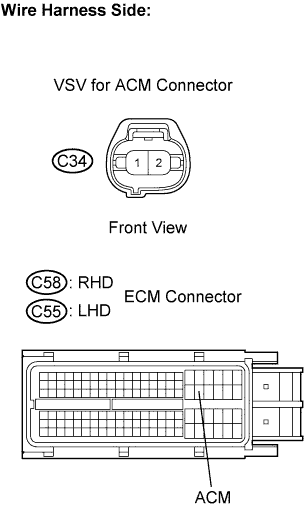

Check the wire harness between the VSV for ACM connector and the ECM connector.

Disconnect the C34 VSV for ACM connector.

Disconnect the C58 (RHD) or C55 (LHD) ECM connector.

Measure the resistance between the wire harness side connectors.

- Standard resistance (Check for open):

- RHD:

Tester Connection

| Specified Condition

|

VSV for ACM (C34-2) - ACM (C58-42)

| Below 1 Ω

|

- LHD:

Tester Connection

| Specified Condition

|

VSV for ACM (C34-2) - ACM (C55-42)

| Below 1 Ω

|

- Standard resistance (Check for short):

- RHD:

Tester Connection

| Specified Condition

|

VSV for ACM (C34-2) or ACM (C58-42) - Body ground

| 10 kΩ or higher

|

- LHD:

Tester Connection

| Specified Condition

|

VSV for ACM (C34-2) or ACM (C55-42) - Body ground

| 10 kΩ or higher

|

Reconnect the ECM connector.

Reconnect the VSV connector.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 7.INSPECT DUTY VACUUM SWITCHING VALVE (VOLTAGE) |

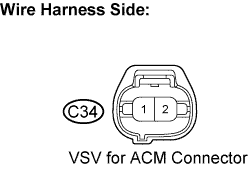

Disconnect the C34 VSV connector.

Turn the ignition switch to the ON position.

Measure the voltage between the terminals.

- Standard voltage:

Tester Connection

| Specified Condition

|

C34-1 - Body ground

| 9 to 14 V

|

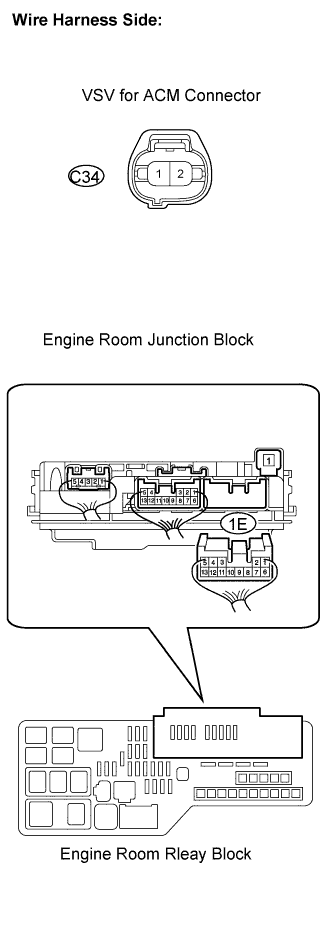

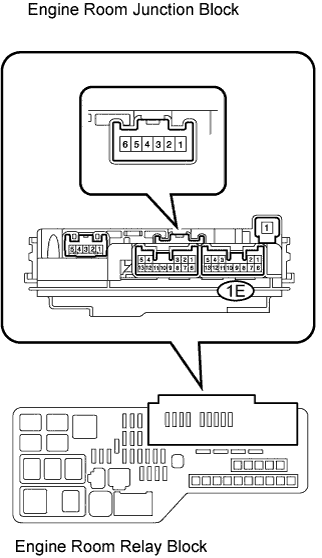

| 8.CHECK HARNESS AND CONNECTOR (VSV FOR ACM - ENGINE JUNCTION BLOCK (EFI RELAY)) |

Check the wire harness between the VSV for ACM and the EFI relay.

Disconnect the C34 VSV connector.

Remove the engine room junction block.

Measure the resistance between the wire harness side connectors.

- Standard resistance:

- Check for open:

Tester Connection

| Specified Condition

|

VSV for ACM (C34-1) - 1E-6 (Engine room relay block)

| Below 1 Ω

|

- Check for short:

Tester Connection

| Specified Condition

|

VSV for ACM (C34-1) or 1E-6 (Engine room relay block) - Body ground

| 10 kΩ or higher

|

Reconnect the VSV for ACM connector.

Reinstall the engine room junction block.

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 9.INSPECT ENGINE ROOM JUNCTION BLOCK (EFI RELAY) |

Remove the engine room junction block.

Measure the EFI relay resistance.

- Standard resistance:

Tester Connection

| Specified Condition

|

1E-12 - 1E-6

| 10 kΩ or higher

|

1E-12 - 1E-6

| Below 1 Ω

(Apply battery voltage between terminals 1E-9 and 1E-10)

|

Reinstall the engine room junction block.

| | REPLACE ENGINE ROOM JUNCTION BLOCK |

|

|