Theft Deterrent System (W/ Entry And Start System) Security Indicator Light Circuit

DESCRIPTION

WIRING DIAGRAM

INSPECTION PROCEDURE

PERFORM ACTIVE TEST USING INTELLIGENT TESTER

CHECK HARNESS AND CONNECTOR (CLOCK ASSEMBLY - CERTIFICATION ECU)

CHECK HARNESS AND CONNECTOR (CLOCK ASSEMBLY - BODY GROUND)

INSPECT CLOCK ASSEMBLY

THEFT DETERRENT SYSTEM (w/ Entry and Start System) - Security Indicator Light Circuit |

DESCRIPTION

Even when the theft deterrent system is in the disarmed state, the security indicator blinks due to a signal output from the immobiliser system. The security indicator blinks continuously due to a continuous signal received from the immobiliser system while it is set or when the theft deterrent system is in the armed state.The certification ECU causes the security indicator to come on only during the arming preparation state and alarm sounding state.

WIRING DIAGRAM

INSPECTION PROCEDURE

| 1.PERFORM ACTIVE TEST USING INTELLIGENT TESTER |

Connect the intelligent tester to the DLC3.

Turn the engine switch on (IG).

Press the intelligent tester main switch on.

Select the item below in the Active Test and then check that the indicator operates.

Smart (Certification ECU):Tester Display

| Test Details

| Diagnostic Note

|

Security Indicator

| Security Indicator ON/OFF

| -

|

- OK:

- The security indicator light flashes or goes off correctly when operating it through the intelligent tester.

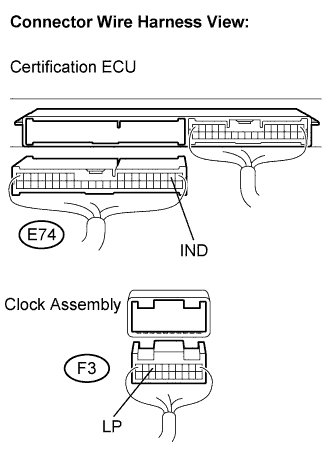

| 2.CHECK HARNESS AND CONNECTOR (CLOCK ASSEMBLY - CERTIFICATION ECU) |

Disconnect the E74 ECU connector.

Disconnect the F3 clock connector.

Measure the resistance according to the value(s) in the table below.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

E74-2 (IND) - F3-8 (LP)

| Always

| Below 1 Ω

|

E74-2 (IND) - Body ground

| Always

| 10 kΩ or higher

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

| 3.CHECK HARNESS AND CONNECTOR (CLOCK ASSEMBLY - BODY GROUND) |

Measure the resistance according to the value(s) in the table below.

- Standard resistance:

Tester Connection

| Condition

| Specified Condition

|

F3-19 (GND1) - Body ground

| Always

| Below 1 Ω

|

| | REPAIR OR REPLACE HARNESS OR CONNECTOR |

|

|

Reconnect the F3 clock connector.

Apply battery voltage between the terminals of the indicator, and check the lighting condition of the security indicator.

- Standard :

Measurement Condition

| Specified Condition

|

Battery positive (+) → Terminal F3-8 (LP)

Battery negative (-) → Terminal F3-19 (GND1)

| Security indicator comes on

|

- NOTICE:

- If the positive (+) lead and the negative (-) lead are incorrectly connected, the security indicator will not come on.

- Voltage of more than 12 V will damage the security indicator.

- If the voltage is too low, the security indicator will not come on.

| OK |

|

|

|

| REPLACE CERTIFICATION ECU (SMART KEY ECU ASSEMBLY) |

|