CONDITIONING FOR SENSOR TESTING

CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0420 AND/OR P0430)

PERFORM ACTIVE TEST USING INTELLIGENT TESTER (A/F CONTROL)

DTC P0420 Catalyst System Efficiency Below Threshold (Bank 1) |

DTC P0430 Catalyst System Efficiency Below Threshold (Bank 2) |

DESCRIPTION

The ECM uses the sensors mounted in front of and behind the Three-Way Catalytic Converter (TWC) to monitor its efficiency.The first sensor, the Air-Fuel Ratio (A/F) sensor, sends pre-catalyst information to the ECM. The second sensor, the Heated Oxygen (HO2) sensor, sends post-catalyst information to the ECM.

In order to detect any deterioration in the TWC, the ECM calculates the Oxygen Storage Capacity (OSC) of the TWC. This calculation is based on the voltage output of the HO2 sensor while performing active air- fuel ratio control, rather than the conventional detecting method, which uses the locus ratio.

The OSC value is an indication of the oxygen storage capacity of the TWC. When the vehicle is being driven with a warm engine, active air-fuel ratio control is performed for approximately 15 to 20 seconds. When it is performed, the ECM deliberately sets the air-fuel ratio to lean or rich level. If a rich-lean cycle of the HO2 sensor is long, the OSC becomes greater. There is a direct correlation between the OSCs of the HO2 sensor and the TWC.

The ECM uses the OSC value to determine the state of the TWC. If any deterioration has occurred, it illuminates the MIL and sets a DTC.

| DTC No. | DTC Detection Condition | Trouble Area |

| P0420 | OSC value is smaller than standard value under active air-fuel ratio control (2 trip detection logic) |

|

| P0430 | OSC value is smaller than standard value under active air-fuel ratio control (2 trip detection logic) |

|

- HINT:

- Bank 1 refers to the bank that includes cylinder No. 1.

- Bank 2 refers to the bank that does not include cylinder No. 1.

- Sensor 1 refers to the sensor closest to the engine assembly.

- Sensor 2 refers to the sensor farthest away from the engine assembly.

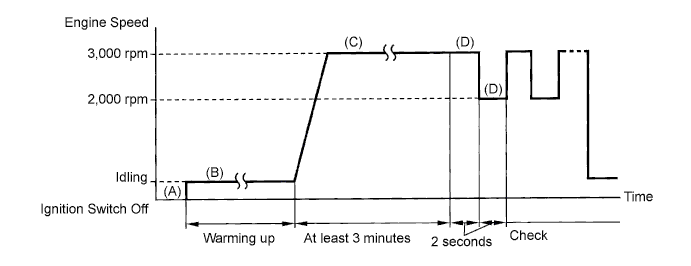

CONDITIONING FOR SENSOR TESTING

Perform the operation with the engine speeds and time durations described below prior to checking the waveforms of the A/F and HO2 sensors. This is performed in order to heat the sensors sufficiently to obtain the appropriate inspection results.

- Connect the intelligent tester to the DLC3 (Procedure "A").

- Start the engine and warm it up with all the accessories switched off, until the engine coolant temperature stabilizes (Procedure "B").

- Run the engine at an engine speed of between 2,500 rpm and 3,000 rpm for at least 3 minutes (Procedure "C").

- While running the engine at 3,000 rpm for 2 seconds and 2,000 rpm for 2 seconds, check the waveforms of the A/F and HO2 sensors using the tester or scan tool (Procedure "D").

- NOTICE:

- The Air-Fuel Ratio (A/F) sensor has an output delay of a few seconds and the Heated Oxygen (HO2) sensor has a maximum delay of approximately 20 seconds.

| Case | A/F Sensor (Sensor 1) Output Voltage | HO2 Sensor (Sensor 2) Output Voltage | Main Suspected Trouble Area | ||

| 1 | Injection Volume +25 % -12.5 % |  | Injection Volume +25 % -12.5 % |  | - |

| Output Voltage More than 3.35 V Less than 3.0 V |  | Output Voltage More than 0.55 V Less than 0.4 V |  | ||

| 2 | Injection Volume +25 % -12.5 % |  | Injection Volume +25 % -12.5 % |  |

|

| Output Voltage Almost no reaction |  | Output Voltage More than 0.55 V Less than 0.4 V |  | ||

| 3 | Injection Volume +25 % -12.5 % |  | Injection Volume +25 % -12.5 % |  |

|

| Output Voltage More than 3.35 V Less than 3.0 V |  | Output Voltage Almost no reaction |  | ||

| 4 | Injection Volume +25 % -12.5 % |  | Injection Volume +25 % -12.5 % |  |

|

| Output Voltage Almost no reaction |  | Output Voltage Almost no reaction |  | ||

- Performing "Control the Injection Volume for A/F Sensor" enables technicians to check and graph the output voltages of both the A/F and HO2 sensors.

INSPECTION PROCEDURE

- HINT:

- Read freeze frame data using the intelligent tester. The ECM records vehicle and driving condition information as freeze frame data the moment a DTC is stored. When troubleshooting, freeze frame data can be helpful in determining whether the vehicle was running or stopped, whether the engine was warmed up or not, whether the air-fuel ratio was lean or rich, as well as other data recorded at the time of a malfunction (CAMRY_ACV40 RM000000PDS01FX.html).

| 1.CHECK ANY OTHER DTCS OUTPUT (IN ADDITION TO DTC P0420 AND/OR P0430) |

Connect the intelligent tester to the DLC3.

Turn the ignition switch to the ON position and turn the tester on.

Enter the following menus: Powertrain / Engine / DTC.

Read the DTCs.

- Result:

Display (DTC output) Proceed to P0420 and/or P0430 A P0420 and/or P0430 and other DTCs B

- HINT:

- If any DTCs other than P0420 or P0430 are output, troubleshoot those DTCs first.

|

| ||||

| A | |

| 2.PERFORM ACTIVE TEST USING INTELLIGENT TESTER (A/F CONTROL) |

Connect the intelligent tester to the DLC3.

Start the engine and turn the tester on.

Warm up the engine at an engine speed of 2,500 rpm for approximately 90 seconds.

On the tester, enter the following menus: Powertrain / Engine / Active Test / Control the Injection Volume for A/F Sensor.

Perform "Control the Injection Volume for A/F Sensor" operation with the engine in an idling condition (press the RIGHT or LEFT button to change the fuel injection volume).

Monitor the output voltages of the A/F and HO2 sensors (AFS B1 S1 and O2S B1 S2 or AFS B2 S1 and O2S B2 S2) displayed on the tester.

- HINT:

- "Control the Injection Volume for A/F Sensor" lowers the fuel injection volume by 12.5 % or increases the injection volume by 25 %.

- Each sensor reacts in accordance with increases and decreases in the fuel injection volume.

Tester Display

(Sensor)Injection Volume Status Voltage AFS B1 S1 or AFS B2 S1

(A/F)+25 % Rich Less than 3.0 V AFS B1 S1 or AFS B2 S1

(A/F)-12.5 % Lean More than 3.35 V O2S B1 S2 or O2S B2 S2

(HO2)+25 % Rich More than 0.55 V O2S B1 S2 or O2S B2 S2

(HO2)-12.5 % Lean Less than 0.4 V - Result:

Status

AFS B1 S1

or

AFS B2 S1Status

O2S B1 S2

or

O2S B2 S2A/F Condition and A/F and

HO2 Sensor ConditionsMisfire Main Suspected Trouble Areas Proceed to Lean/Rich Lean/Rich Normal - - Three-Way Catalytic Converter (TWC)

- Gas leakage from exhaust system

A Lean Lean/Rich A/F sensor malfunction - - A/F sensor

B Rich Lean/Rich A/F sensor malfunction May occur - A/F sensor

B Lean/Rich Lean HO2 sensor malfunction - - HO2 sensor

- Gas leakage from exhaust system

C Lean/Rich Rich HO2 sensor malfunction - - HO2 sensor

- Gas leakage from exhaust system

C Lean Lean Actual air-fuel ratio lean May occur - Extremely rich or lean actual air-fuel ratio

- Gas leakage from exhaust system

A Rich Rich Actual air-fuel ratio lean - - Extremely rich or lean actual air-fuel ratio

- Gas leakage from exhaust system

A - Three-Way Catalytic Converter (TWC)

- Lean:

- During "Control the Injection Volume for A/F Sensor", the A/F sensor (AFS) output voltage is consistently more than 3.35 V, and the HO2 sensor output voltage (O2S) is consistently less than 0.4 V.

- Rich:

- During "Control the Injection Volume for A/F Sensor", the AFS is consistently less than 3.0 V, and the O2S is consistently more than 0.55 V.

- Lean/Rich:

- During "Control the Injection Volume for A/F Sensor" of the Active Test, the output voltage of the HO2 sensor alternates correctly.

|

| ||||

|

| ||||

| A | |

| 3.CHECK FOR EXHAUST GAS LEAKS |

- OK:

- No gas leakage.

|

| ||||

| OK | ||

| ||