1. INSTALL NO. 2 CYLINDER HEAD GASKET

-

Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the cylinder head and cylinder block.

-

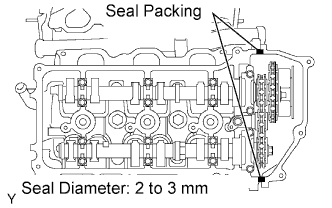

Apply seal packing to a new cylinder head gasket as shown in the illustration.

Seal packing:

Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

Standard seal diameter:

2.5 to 3.0 mm (0.0984 to 0.118 in.)

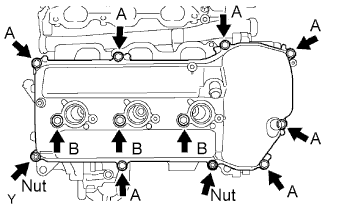

Seal Packing Application Range Item Specified Condition A 10 to 15 mm (0.394 to 0.591 in.) B 1.25 to 1.5 mm (0.0492 to 0.0591 in.) HINT:

- Remove any oil from the contact surface.

- Install the cylinder head gasket within 3 minutes after applying the seal packing.

- Do not add engine oil within 2 hours of installation.

-

Place the cylinder head gasket on the cylinder block surface with the front face of the Lot No. stamp upward.

NOTICE:

Be careful of the installation direction.

2. INSTALL CYLINDER HEAD SUB-ASSEMBLY LH

-

Place the cylinder head on the cylinder head gasket.

NOTICE:

- Ensure that no oil is on the mounting surface of the cylinder head.

- Gently place the cylinder head in order not to damage the gasket with the bottom part of the cylinder head.

-

Install the 8 cylinder head bolts and plate washers.

HINT:

- The cylinder head bolts are tightened in 3 progressive steps.

- If any cylinder head bolt is broken or deformed, replace it.

-

Apply a light coat of engine oil to the threads and under the heads of the cylinder head bolts.

-

Install the plate washers to the cylinder head bolts.

-

Step 1:

-

Using a 10 mm bi-hexagon wrench, install and uniformly tighten the 8 cylinder head bolts with plate washers in several steps in the sequence shown in the illustration.

Torque:

36 N*m{ 367 kgf*cm , 27 ft.*lbf }

If any one of the cylinder head bolts does not meet the torque specification, replace the cylinder head bolt.

-

-

Step 2:

-

Mark the cylinder head bolt heads with paint as shown in the illustration.

-

Tighten the cylinder head bolts 180° in the sequence shown in step 1.

-

-

Check that the painted marks are now facing rearward.

-

Install the 2 bolts in the order shown in the illustration.

-

Apply a light coat of engine oil to the threads of the cylinder head bolts.

-

Install the 2 cylinder head bolts. Using several steps, tighten the bolts uniformly in the sequence shown in the illustration.

Torque:

30 N*m{ 306 kgf*cm , 22 ft.*lbf }

-

-

Seal packing will seep out from the front side of the engine. Thoroughly wipe off seal packing that seeps out.

3. INSTALL NO. 3 CAMSHAFT AND NO. 4 CAMSHAFT

NOTICE:

As the thrust clearance of the camshaft is small, the camshaft must be kept level while it is being installed. If the camshaft is not kept level, the portion of the cylinder head which receives the shaft thrust may crack or be damaged, causing the camshaft to seize or break. To avoid this, the following steps should be carried out.

-

Set the crankshaft position.

-

Install the crankshaft pulley set bolt, turn the crankshaft, and set the crankshaft set key into the left horizontal position.

NOTICE:

Setting the crankshaft at a wrong angle can cause the piston head and valve head to come into contact with each other when the camshaft is installed, causing damage. Always set the crankshaft to the correct angle.

-

-

Apply a light coat of engine oil to the thrust portions and journals of the camshafts.

-

Place the 2 camshafts onto the cylinder head with the cam lobes of the No. 2 cylinder facing each direction as shown in the illustration.

-

Apply a light coat of engine oil to the 8 bearing caps.

-

Set the 8 bearing caps in their proper locations.

-

Apply a light coat of engine oil to the threads and under the heads of the 16 bearing cap bolts.

-

Uniformly install the 16 bearing cap bolts in several steps in the order shown in the illustration.

Torque:

for 10 mm head bolt:

9.0 N*m{ 92 kgf*cm , 80 in.*lbf }

for 12 mm head bolt:

24 N*m{ 245 kgf*cm , 18 ft.*lbf }

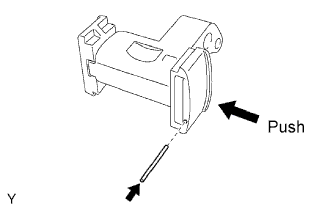

4. INSTALL NO. 3 CHAIN TENSIONER ASSEMBLY

-

While pushing in the tensioner, insert a pin of ?1.0 mm (0.0394 in.) into the hole to fix the tensioner in place.

-

Install the No. 3 chain tensioner with the bolt.

Torque:

21 N*m{ 214 kgf*cm , 15 ft.*lbf }

5. INSTALL CYLINDER HEAD GASKET

-

Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the cylinder head and cylinder block.

-

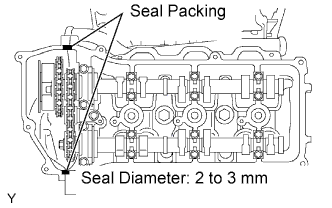

Apply seal packing to a new cylinder head gasket as shown in the illustration.

Seal packing:

Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

Standard seal diameter:

2.5 to 3.0 mm (0.0984 to 0.118 in.)

Seal Packing Application Range Item Specified Condition A 10 to 15 mm (0.394 to 0.591 in.) B 1.25 to 1.5 mm (0.0492 to 0.0591 in.) HINT:

- Remove any oil from the contact surface.

- Install the cylinder head gasket within 3 minutes after applying the seal packing.

- Do not add engine oil within 2 hours of installation.

-

Place the cylinder head gasket on the cylinder block surface with the front face of the Lot No. stamp upward.

NOTICE:

Be careful of the installation direction.

6. INSTALL CYLINDER HEAD SUB-ASSEMBLY RH

-

Place the cylinder head on the cylinder head gasket.

NOTICE:

- Ensure that no oil is on the mounting surface of the cylinder head.

- Gently place the cylinder head in order not to damage the gasket with the bottom part of the cylinder head.

-

Install the 8 cylinder head bolts and plate washers.

HINT:

- The cylinder head bolts are tightened in 3 progressive steps.

- If any cylinder head bolt is broken or deformed, replace it.

-

Apply a light coat of engine oil to the threads and under the heads of the cylinder head bolts.

-

Install the plate washers to the cylinder head bolts.

-

Step 1:

-

Using a 10 mm bi-hexagon wrench, install and uniformly tighten the 8 cylinder head bolts with plate washers in several steps in the sequence shown in the illustration.

Torque:

36 N*m{ 367 kgf*cm , 27 ft.*lbf }

If any one of the cylinder head bolts does not meet the torque specification, replace the cylinder head bolt.

-

-

Step 2:

-

Mark the cylinder head bolt heads with paint as shown in the illustration.

-

Tighten the cylinder head bolts 180° in the sequence shown in step 1.

-

-

Check that the painted marks are now facing rearward.

-

Seal packing will seep out from the front side of engine. Thoroughly wipe off the seal packing that seeps out.

7. INSTALL NO. 1 CAMSHAFT BEARING

-

Align the bearing claw with the claw groove of the bearing cap, and push in the No. 1 camshaft bearing.

NOTICE:

- Install the bearing while aligning it with the oil hole in the bearing cap.

- Clean the backside of the bearing and the contact surface of the bearing cap and prevent oil from adhering to them.

8. INSTALL NO. 2 CAMSHAFT BEARING

-

Install the No. 2 camshaft bearing to the cylinder head.

NOTICE:

Clean the backside of the bearing and the contact surface of the cylinder head and prevent oil from adhering to them.

9. INSTALL NO. 1 CAMSHAFT AND NO. 2 CAMSHAFT

NOTICE:

As the thrust clearance of the camshaft is small, the camshaft must be kept level while it is being installed. If the camshaft is not kept level, the portion of the cylinder head which receives the shaft thrust may crack or be damaged, causing the camshaft to seize or break. To avoid this, the following steps should be carried out.

-

Set the crankshaft position.

-

Using the crankshaft pulley set bolt, turn the crankshaft, and set the crankshaft set key into the left horizontal position.

NOTICE:

Having the crankshaft at the wrong angle can cause the piston head and valve head to come into contact with each other when the camshaft is installed, causing damage. Always set the crankshaft to the correct angle.

-

-

Apply a light coat of engine oil to the thrust portions and journals of the camshafts.

-

Place the 2 camshafts onto the cylinder head with the cam lobes of the No. 1 cylinder facing each direction as shown in the illustration.

-

Apply a light coat of engine oil to the 8 bearing caps.

-

Set the 8 bearing caps in their proper locations.

-

Apply a light coat of engine oil to the threads and under the heads of the 16 bearing cap bolts.

-

Uniformly install the 16 bearing cap bolts in several steps in the order shown in the illustration.

Torque:

for 10 mm head bolt:

9.0 N*m{ 92 kgf*cm , 80 in.*lbf }

for 12 mm head bolt:

24 N*m{ 245 kgf*cm , 18 ft.*lbf }

-

Using a wrench, turn the camshafts clockwise until the camshaft knock pin is at a position 90° to the cylinder head.

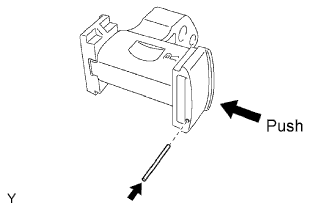

10. INSTALL NO. 2 CHAIN TENSIONER ASSEMBLY

-

While pushing in the tensioner, insert a pin of ?1.0 mm (0.0394 in.) into the hole to fix the tensioner in place.

-

Install the No. 2 chain tensioner with the bolt.

Torque:

21 N*m{ 214 kgf*cm , 15 ft.*lbf }

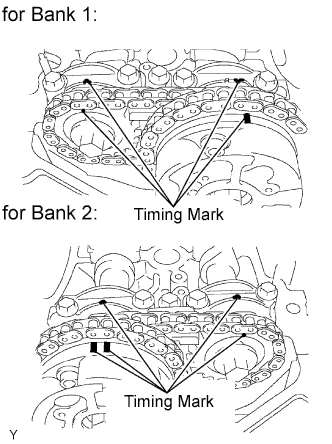

11. INSTALL CAMSHAFT TIMING GEARS AND NO. 2 CHAIN

-

Align the mark links (yellow) of the No. 2 chain with the timing marks (1-dot mark) of the camshaft timing gear and sprocket as shown in the illustration.

-

Align the timing marks on the camshaft timing gear and sprocket with the timing marks on the bearing caps, and install the camshaft timing gear and sprocket with the No. 2 chain to the camshafts.

-

Temporarily install the camshaft timing gear set bolt and camshaft timing sprocket set bolt.

NOTICE:

Do not push the camshaft timing gear assembly to the camshaft forcibly when installing it.

-

Hold the hexagonal portion of the camshaft with a wrench, and tighten the 2 bolts.

Torque:

100 N*m{ 1020 kgf*cm , 74 ft.*lbf }

-

Remove the pin from the No. 2 chain tensioner.

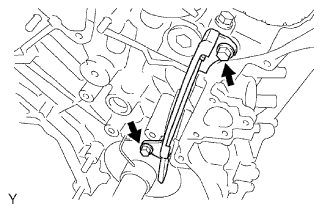

12. INSTALL NO. 1 CHAIN VIBRATION DAMPER

-

Install the No. 1 chain vibration damper with the 2 bolts.

Torque:

19 N*m{ 194 kgf*cm , 14 ft.*lbf }

13. INSTALL CHAIN TENSIONER SLIPPER

14. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY

-

While turning the stopper plate of the tensioner clockwise, push in the plunger of the tensioner as shown in the illustration.

-

While turning the stopper plate of the tensioner counterclockwise, insert a bar of ?3.5 mm (0.138 in.) into the holes on the stopper plate and tensioner to fix the stopper plate in place.

-

Install the chain tensioner with the 2 bolts.

Torque:

10 N*m{ 102 kgf*cm , 7 ft.*lbf }

15. INSTALL NO. 1 CHAIN SUB-ASSEMBLY

-

Set the No. 1 cylinder to TDC/compression.

-

Align the timing marks of the camshaft timing gears and sprockets with the timing marks of the bearing caps.

-

Install the crankshaft pulley set bolt, and turn the crankshaft to align the crankshaft set key with the timing line of the cylinder block.

-

-

Align the mark link (yellow) with the timing mark of the crankshaft timing gear.

-

Align the mark links (orange) with the timing marks of the camshaft timing gears, and install the No. 1 chain.

16. INSTALL NO. 2 CHAIN VIBRATION DAMPER

-

Install the 2 No. 2 chain vibration dampers.

17. INSTALL NO. 1 IDLE GEAR SHAFT

-

Apply a light coat of engine oil to the rotating surface of the No. 1 idle gear shaft.

-

Temporarily install the No. 1 idle gear shaft and No. 1 idle gear with the No. 2 idle gear shaft while aligning the knock pin of the No. 1 idle gear shaft with the knock pin groove of the cylinder block.

NOTICE:

Be careful of the idle gear direction.

-

Using a 10 mm hexagon wrench, tighten the No. 2 idle gear shaft.

Torque:

60 N*m{ 612 kgf*cm , 44 ft.*lbf }

-

Remove the bar from the chain tensioner.

18. INSTALL FRONT CRANKSHAFT OIL SEAL

-

Using SST and a hammer, tap in a new oil seal until its surface is flush with the timing chain cover edge.

SST

09226-10010

NOTICE:

- Keep the lip free from foreign matter.

- Do not tap the oil seal at an angle.

-

Apply MP grease to the lip of the oil seal.

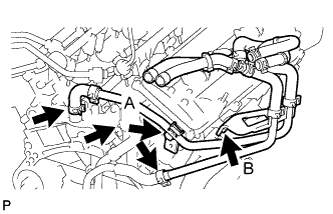

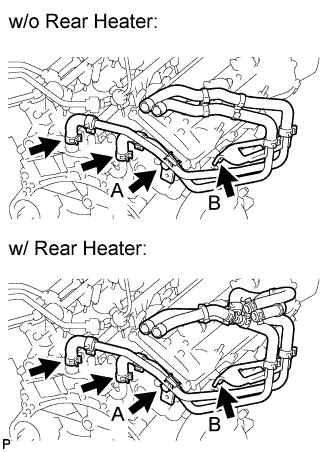

19. INSTALL TIMING CHAIN COVER SUB-ASSEMBLY

-

Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the timing chain cover, cylinder head and cylinder block.

-

Install a new O-ring to the cylinder head for bank 2 as shown in the illustration.

-

Apply seal packing as shown in the illustration.

Seal packing:

Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

Standard seal diameter:

3.0 to 4.0 mm (0.118 to 0.157 in.)

-

Apply seal packing in a continuous line to the timing chain cover as shown in the illustration.

Seal packing:

for water related part:

Toyota Genuine Seal Packing 1282B, Three Bond 1282B or equivalent

for oil related part:

Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

Standard seal diameter:

3.5 to 4.5 mm (0.138 to 0.177 in.)

HINT:

Water related parts are labeled "B" in the illustration.

NOTICE:

- Install the timing chain cover within 3 minutes after applying seal packing. After installing it, the timing chain cover bolts and nuts must be tightened within 15 minutes. Otherwise the seal packing must be removed and reapplied.

- Do not apply seal packing to "A" shown in the illustration.

-

Align the keyway of the oil pump drive rotor with the rectangular portion of the crankshaft timing gear, and slide the timing chain cover into place.

-

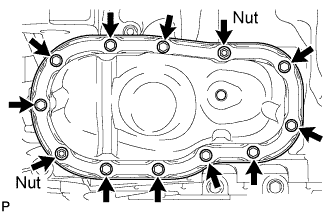

Install the timing chain cover with the 24 bolts labeled A and B, and the 2 nuts. Tighten the bolts and nuts uniformly in several steps.

Torque:

23 N*m{ 235 kgf*cm , 17 ft.*lbf }

NOTICE:

- Make sure not to wrap the No. 1 chain and slipper over the timing chain cover seal line.

- Install the timing chain cover 15 minutes or more after installing the water pump.

Standard Bolt:

Item Quantity Length Bolt A 9 25 mm (0.984 in.) Bolt B 15 55 mm (2.17 in.) NOTICE:

Make sure that there is no oil on the bolt threads.

20. INSTALL OIL FILTER BRACKET SUB-ASSEMBLY

-

Set a new O-ring to the timing chain cover.

-

Install the oil filter bracket with the 3 bolts and 2 nuts.

Torque:

19 N*m{ 194 kgf*cm , 14 ft.*lbf }

21. INSTALL WATER INLET HOUSING

-

Apply soapy water to a new O-ring, install it to the water outlet pipe.

-

Install a new O-ring to the water pump.

-

Install a new gasket to the water pump.

-

Install the water inlet with the 5 bolts.

Torque:

9.0 N*m{ 92 kgf*cm , 80 in.*lbf }

22. INSTALL OIL COOLER HOSE

-

Install the oil cooler hose.

23. INSTALL NO. 2 OIL COOLER HOSE

-

Install the oil cooler hose.

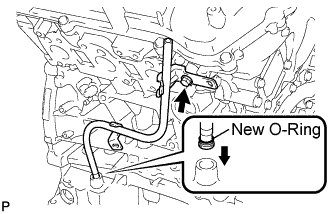

24. INSTALL OIL PAN SUB-ASSEMBLY

-

Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the cylinder block, rear oil seal retainer and oil pan.

-

Install a new O-ring to the timing chain cover.

Text in Illustration *1 New O-Ring

-

Apply seal packing in a continuous line as shown in the illustration.

Seal packing:

Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

Standard seal diameter:

3 to 4 mm (0.118 to 0.157 in.)

Text in Illustration *1 Seal Packing NOTICE:

- Remove any oil from the contact surface.

- Install the oil pan within 3 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after installing.

-

Install the oil pan with the 17 bolts (A, B and C) and 2 nuts. Tighten the bolts and nuts uniformly in several steps.

Torque:

for bolt A, B and nut:

21 N*m{ 214 kgf*cm , 15 ft.*lbf }

for bolt C:

10 N*m{ 102 kgf*cm , 7 ft.*lbf }

Text in Illustration

Bolt A

Bolt B

Bolt C

Nut Standard Bolt:

Item Quantity Length A 6 25 mm (0.984 in.) B 9 45 mm (1.77 in.) C 2 14 mm (0.551 in.)

25. INSTALL OIL STRAINER SUB-ASSEMBLY

-

Install a new gasket to the oil strainer.

Text in Illustration *1 Groove *2 Protrusion HINT:

Align the protrusion of the gasket with the groove of the oil strainer.

-

Install the oil strainer with the 2 nuts.

Torque:

9.0 N*m{ 92 kgf*cm , 80 in.*lbf }

26. INSTALL NO. 2 OIL PAN SUB-ASSEMBLY

-

Apply seal packing in a continuous line as shown in the illustration.

Seal packing:

Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

Standard seal diameter:

3 to 4 mm (0.118 to 0.157 in.)

NOTICE:

- Remove any oil from the contact surface.

- Install the No. 2 oil pan within 3 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after the installation.

-

Install the No. 2 oil pan with the 10 bolts and 2 nuts. Tighten the bolts and nuts uniformly in several steps.

Torque:

for bolt:

9.0 N*m{ 92 kgf*cm , 81 in.*lbf }

for nut:

10 N*m{ 102 kgf*cm , 7 ft.*lbf }

27. INSTALL CRANKSHAFT PULLEY

-

Using SST, install the crankshaft pulley with the pulley set bolt.

SST

09213-54015 (91651-60855) 09330-00021

Torque:

250 N*m{ 2549 kgf*cm , 184 ft.*lbf }

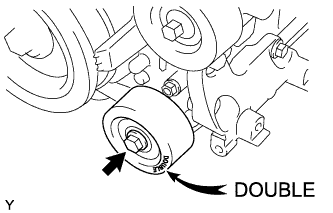

28. INSTALL NO. 1 IDLER PULLEY SUB-ASSEMBLY

-

Install the No. 1 idler pulley with the bolt.

Torque:

54 N*m{ 551 kgf*cm , 40 ft.*lbf }

HINT:

"DOUBLE" is marked on the No. 1 idler pulley to distinguish it from the No. 2 idler pulley.

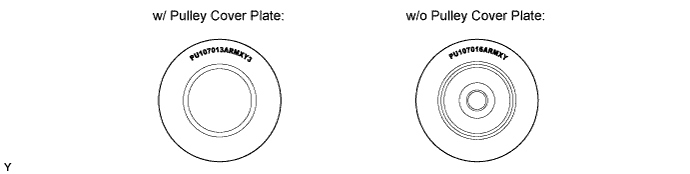

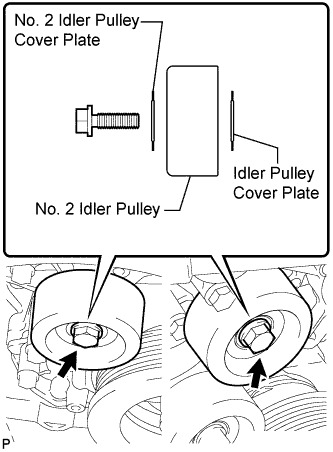

29. INSTALL NO. 2 IDLER PULLEY SUB-ASSEMBLY

-

w/ Pulley Cover Plate:

-

Install the idler pulley cover plate, idler pulley and No. 2 idler pulley cover plate with the bolt.

Torque:

54 N*m{ 551 kgf*cm , 40 ft.*lbf }

NOTICE:

If it is necessary to replace the pulley or either plate, replace the No. 2 idler pulley cover plate, No. 2 idler pulley and idler pulley cover plate as a set with new parts.

-

-

w/o Pulley Cover Plate: Install the 2 No. 2 idler pulleys with the 2 bolts.

Torque:

54 N*m{ 551 kgf*cm , 40 ft.*lbf }

30. INSTALL V-RIBBED BELT TENSIONER ASSEMBLY

-

Temporarily install the V-ribbed belt tensioner with the 5 bolts.

-

Tighten bolt 1 and 2 in numerical order.

Torque:

36 N*m{ 367 kgf*cm , 27 ft.*lbf }

-

Tighten the other bolts.

Torque:

36 N*m{ 367 kgf*cm , 27 ft.*lbf }

Standard Bolt:

Item Length A 70 mm (2.76 in.) B 33 mm (1.30 in.)

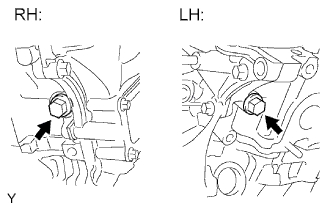

31. INSTALL OIL CONTROL VALVE FILTER

-

Install 2 new gaskets to 2 new unions.

-

Insert new filters to the unions.

-

Apply adhesive to 2 or 3 threads of the unions.

Adhesive:

Toyota Genuine Adhesive 1344, Three Bond 1344 or equivalent

-

Install the unions to the cylinder head LH and RH.

Torque:

62 N*m{ 632 kgf*cm , 46 ft.*lbf }

32. INSTALL REAR WATER BY-PASS JOINT

-

Apply soapy water to a new O-ring.

-

Install the O-ring to the water outlet pipe, and set 2 new gaskets to the water ports LH and RH.

-

Install the rear water by-pass joint with the 2 bolts and 4 nuts.

Torque:

for bolt:

10 N*m{ 102 kgf*cm , 7 ft.*lbf }

for nut:

9.0 N*m{ 92 kgf*cm , 80 in.*lbf }

-

Connect the engine coolant temperature sensor connector.

33. INSTALL WATER HOSE SUB-ASSEMBLY (for Automatic Transmission)

-

Temporarily install the heater water pipe, and then tighten the 2 bolts.

Torque:

for bolt A:

9.8 N*m{ 100 kgf*cm , 87 in.*lbf }

for bolt B:

13 N*m{ 138 kgf*cm , 10 ft.*lbf }

-

Connect the 3 water hoses.

34. INSTALL WATER HOSE SUB-ASSEMBLY (for Manual Transmission)

-

Temporarily install the heater water pipe, and then tighten the 2 bolts.

Torque:

for bolt A:

9.8 N*m{ 100 kgf*cm , 87 in.*lbf }

for bolt B:

13 N*m{ 138 kgf*cm , 10 ft.*lbf }

-

Connect the 2 water hoses.

35. INSTALL ENGINE OIL LEVEL DIPSTICK GUIDE

-

Install a new O-ring to the dipstick guide.

-

Apply a light coat of engine oil to the O-ring.

-

Push the dipstick guide end into the guide hole.

-

Install the dipstick guide with the bolt.

Torque:

9.0 N*m{ 92 kgf*cm , 80 in.*lbf }

36. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY RH

-

Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the cylinder head, timing chain cover and cylinder head cover.

-

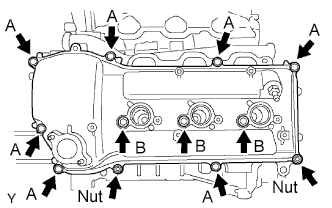

Apply seal packing as shown in the illustration.

Seal packing:

Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

Standard seal diameter:

2 to 3 mm (0.0787 to 0.118 in.)

NOTICE:

- Remove any oil from the contact surface.

- Install the head cover within 3 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after the installation.

-

Install a new gasket to the cylinder head cover.

-

Install the seal washers to the bolts.

-

Temporarily install the cylinder head cover with the 10 bolts and 2 nuts. Tighten the bolts and nuts uniformly in several steps.

Torque:

for bolt A:

10 N*m{ 102 kgf*cm , 7 ft.*lbf }

for bolt B and nut:

9.0 N*m{ 92 kgf*cm , 80 in.*lbf }

37. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY LH

-

Remove any old packing (FIPG) material and be careful not to drop any oil on the contact surfaces of the cylinder head, timing chain cover and cylinder head cover.

-

Apply seal packing as shown in the illustration.

Seal packing:

Toyota Genuine Seal Packing Black, Three Bond 1207B or equivalent

Standard seal diameter:

2 to 3 mm (0.0787 to 0.118 in.)

NOTICE:

- Remove any oil from the contact surface.

- Install the head cover within 3 minutes after applying seal packing.

- Do not start the engine for at least 2 hours after the installation.

-

Install a new gasket to the cylinder head cover.

-

Install the seal washers to the bolts.

-

Temporarily install the cylinder head cover with the 10 bolts and 2 nuts. Tighten the bolts and nuts uniformly in several steps.

Torque:

for bolt A:

10 N*m{ 102 kgf*cm , 7 ft.*lbf }

for bolt B and nut:

9.0 N*m{ 92 kgf*cm , 80 in.*lbf }

38. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY LH

-

Apply a light coat of engine oil to a new O-ring and install it to the oil control valve.

-

Install the oil control valve with the bolt.

Torque:

10 N*m{ 102 kgf*cm , 7 ft.*lbf }

NOTICE:

- Do not allow foreign matter to contact the oil seal face of the oil control valve (connecting surface with cylinder head).

- Be careful that the O-ring is not cracked when installing the oil control valve.

-

Connect the oil control valve connector.

39. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE ASSEMBLY RH

-

Apply a light coat of engine oil to a new O-ring and install it to the oil control valve.

-

Install the oil control valve with the bolt.

Torque:

10 N*m{ 102 kgf*cm , 7 ft.*lbf }

NOTICE:

- Do not allow foreign matter to contact the oil seal face of the oil control valve (connecting surface with cylinder head).

- Be careful that the O-ring is not cracked when installing the oil control valve.

-

Connect the camshaft timing oil control valve connector.

40. INSTALL VVT SENSOR (for Bank 2)

-

Apply a light coat of engine oil to the O-ring of the VVT sensor.

NOTICE:

- When reusing the sensor, inspect the O-ring.

- If the O-ring has scratches or cuts, replace the sensor.

-

Install the VVT sensor with the bolt.

Torque:

8.0 N*m{ 82 kgf*cm , 71 in.*lbf }

-

Connect the sensor connector.

41. INSTALL VVT SENSOR (for Bank 1)

-

Apply a light coat of engine oil to the O-ring of the sensor.

NOTICE:

- When reusing the sensor, inspect the O-ring.

- If the O-ring has scratches or cuts, replace the sensor.

-

Install the sensor with the bolt.

Torque:

8.0 N*m{ 82 kgf*cm , 71 in.*lbf }

-

Connect the sensor connector.

42. INSTALL SPARK PLUG

-

Install the 6 spark plugs.

Torque:

20 N*m{ 204 kgf*cm , 15 ft.*lbf }

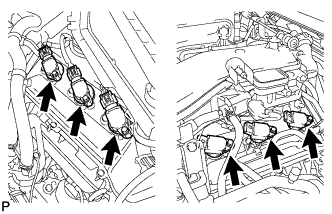

43. INSTALL IGNITION COIL ASSEMBLY

-

Install the 6 ignition coils with the 6 bolts.

Torque:

9.0 N*m{ 92 kgf*cm , 80 in.*lbf }

-

Connect the 6 ignition coil connectors.

44. INSTALL ENGINE ASSEMBLY

-

Install the engine assembly.